Are Fire Adapters the Most Overlooked Part of Your Home Fire Safety Plan?

In a fire, every second counts. Imagine firefighters arriving, ready to help, only to find their equipment is useless because it can't connect to your water source.

A fire adapter is a precision-made coupling that acts as a bridge between two different types of hose or hydrant connections. It ensures that any firefighter's hose can immediately connect to your system, eliminating a critical and potentially catastrophic delay during an emergency.

This is the ultimate example of interface design, a concept Jacky, you and I live by every day. When we design a mold, we have to ensure it perfectly fits the standard platen of an injection molding machine. We use locating rings and standardized bolt patterns. A fire adapter serves the same function but under the most extreme pressure imaginable. It's a small, inexpensive part that solves a huge compatibility problem, ensuring two critical systems can talk to each other when failure is not an option. It's not just a piece of hardware; it's a guarantee of interoperability.

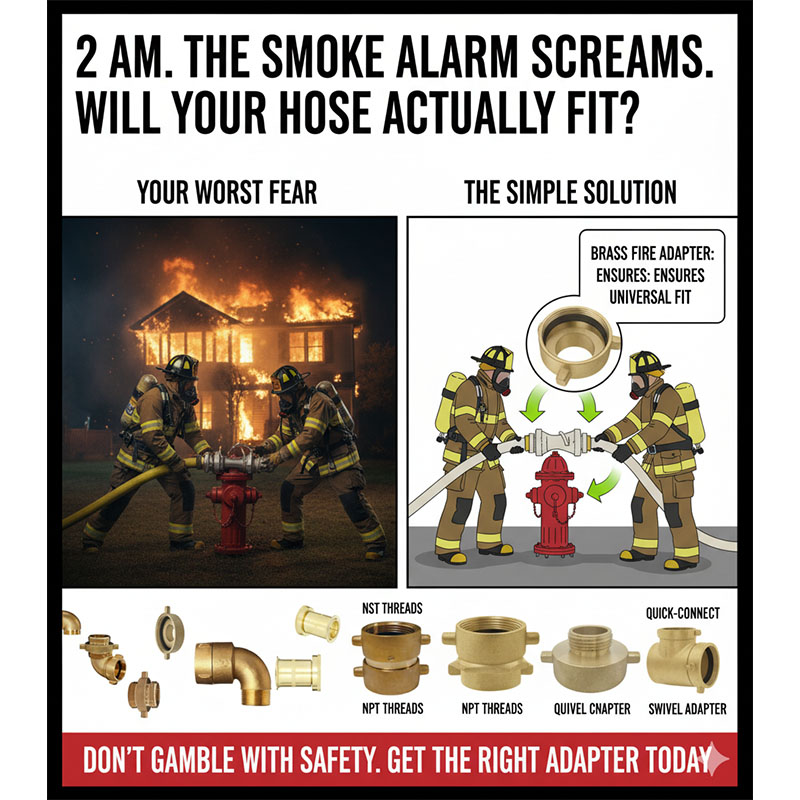

It's 2 AM and the Fire Truck is Here; Will Their Hose Actually Fit Your Connection?

The smoke alarm is screaming, and you see flashing lights. But what if the first responders face an unexpected delay that has nothing to do with their response time?

This nightmare scenario happens. If your property has a private hydrant or a standpipe connection, it may have a different thread type than the one your local fire department uses. Without an adapter, they simply cannot connect their hoses to your water source.

The core of this problem lies in a lack of standardization over time and across different regions. It’s a design issue at a civic level. In my manufacturing world, this would be like having three different suppliers send us mold bases with three different, non-standard leader pin spacings. Our entire production would grind to a halt because the two halves of the tool couldn't align. The fire adapter is the custom jig we'd have to machine on the spot to make it work. But in a fire, you don't have time to machine a custom solution. You need that solution in hand, ready to go. As a designer, Jacky, you understand that a system is only as strong as its weakest interface. In home fire safety, that interface is often the hose-to-hydrant connection.

What is a Fire Adapter, and Why is it More Than Just a Metal Coupling?

You might think it's just a simple piece of brass. But this small part carries an immense responsibility, and its design reflects that in ways you can't see.

A fire adapter is a precisely machined connector designed to join fire hoses, hydrants, or appliances that have mismatched thread sizes or types. It is engineered to withstand extremely high pressures and rapid temperature changes without leaking or failing.

Let's look at this from a material and manufacturing perspective. These aren't cheap, cast-pot-metal parts. Most high-quality adapters are forged or machined from brass or aluminum alloys. Brass is chosen for its corrosion resistance and durability. Aluminum is used for its light weight. The threads aren't just cut; they are often rolled for superior strength and a smoother finish, which is critical for making a fast, secure seal. The hexagonal flats for wrenches are designed to allow for high torque without stripping. In my CNC business, we machined parts with similar requirements for hydraulic systems. The tolerances have to be tight because a small leak at 50 PSI becomes a catastrophic failure at 300 PSI. So, while it may look like a simple coupling, it is a purpose-built, high-performance piece of safety equipment.

How Can a $50 Adapter Prevent a Total Loss of Your Home in a Fire?

You spend money on smoke detectors and insurance. But what if the single most effective piece of equipment to save your home costs less than a family dinner?

A $50 adapter is the key that unlocks a multi-thousand-gallon-per-minute water supply. It can be the difference between a small, contained fire and a total, devastating loss. The cost of the adapter is insignificant compared to the value it protects.

This is a classic case of risk mitigation through a small, targeted investment. As an engineer, Jacky, you deal with this all the time. It's about identifying the single point of failure that could cascade into a system-wide disaster. In a complex injection mold, we might add a $10 sensor to monitor a slide lock. Why? Because if that slide closes at the wrong time, it causes a $50,000 tool crash. The sensor's cost is nothing compared to the damage it prevents. Your fire adapter is that sensor. It's a passive device that only has one job, but its ability to perform that job is what allows the entire firefighting system to function as designed. Forgetting this component is like designing a fire suppression system with a locked valve and no key.

What's the Difference Between NPT, Storz, and Garden Hose Threads?

You know you need an adapter, but the terminology is confusing. Choosing the wrong thread type is just as bad as having no adapter at all.

These are different standards for connecting hoses and pipes. NPT and NST are traditional threaded systems, Storz is a quick-connect system, and GH is the standard for garden hoses. Knowing which ones your fire department and your home use is critical.

Understanding thread standards is crucial in engineering. When designing a mold's cooling system, we have to specify the exact fittings—NPT, BSPT, etc.—or a leak is guaranteed. It's the same here, but for firefighters. The key is to know what you have and what they have. Your job is to buy the bridge between the two. Here’s a quick breakdown:

| Thread Type | Common Use | Description |

|---|---|---|

| NST/NH | Fire Hoses & Hydrants (USA) | National Hose/National Standard. Coarse, durable threads. |

| NPT | Pipes & Industrial (USA) | National Pipe Tapered. Tapered threads create a seal. |

| Storz | Modern Fire Hydrants/Hoses | A genderless, threadless quarter-turn quick-connect. |

| GH | Garden Hoses | Standard Garden Hose thread. Not for high-pressure fire use. |

Your first step is a simple phone call to your local non-emergency fire department number. Ask them what thread standard they use on their trucks. Then, look at your own connection. That information is all you need to buy the perfect adapter.

How Do You Choose the Right Fire Adapter in Just 5 Minutes?

The options seem endless, and you're worried about making the wrong choice. You don't need to be an expert to get this right; you just need a simple checklist.

Choosing the right adapter is a quick process of matching four key things: the inlet type, the outlet type, the material, and ensuring it has the proper approvals for safety.

This is pure requirements-driven design, Jacky. You're not inventing something; you're selecting a component based on a clear set of needs. It's just like picking the right hot runner nozzle for a specific plastic and gate size. Here is your 5-minute checklist to get it right every time:

- Identify Your Connection (Inlet): Look at your home's standpipe or hydrant. Is it male or female? What is the diameter (e.g., 2.5 inches)? What is the thread type (likely NPT or NST)? Write this down.

- Confirm the Fire Dept. Connection (Outlet): Call your local fire department's non-emergency line. Ask for the size and thread type of their primary attack hoses. They will gladly tell you (it's often 2.5" NST or a 4" Storz).

- Choose the Material: For most home applications, brass is the best choice. It's durable, corrosion-resistant, and can be left in place for years without seizing up.

- Check for Approvals: If possible, look for adapters that are UL or FM approved. This means they've been independently tested to meet high safety and performance standards.

- Match Them Up: Find the adapter that says "2.5" Female NPT to 2.5" Male NST" (or whatever your specific requirements are). It's that simple.

Why Should You Test Your Fire Adapter, and What's the Drill?

You bought the adapter and it's sitting in a box. You assume it will work, but assumptions in safety systems can be fatal. This is a critical final step.

You must test the adapter to ensure it threads on smoothly and correctly to your connection before an emergency. A simple annual drill ensures it hasn't seized, been misplaced, or have damaged threads, confirming it's ready when you need it most.

In manufacturing, we never ship a new mold without a full trial. We call it a "mold qualification" process. We test every single function under real-world conditions to prove it works as designed. This is your personal mold qualification for your fire adapter. You don't need to blast water. The drill is simple, safe, and dry. Once a year, take your adapter and physically thread it onto your home's connection. Does it go on smoothly by hand for the first few turns? Does it tighten fully with a wrench? Then, unthread it. That's it. This five-minute annual check confirms three things: you know where the adapter is, you know it fits, and the threads are clean and functional. It transforms a piece of hardware in a drawer into a proven, reliable piece of your home safety plan.

Is Your Home's Invisible Guardian in Place and Ready?

You've installed smoke alarms and have a fire extinguisher. But you are likely still missing the one device that allows the professionals to do their job effectively.

The fire adapter is that invisible guardian. It stands ready, silently ensuring that when help arrives, a simple mismatched thread won't stand in the way of saving your home and family. Having the right one on-site and tested is the final link in your safety chain.

As designers and engineers, Jacky, we have a deep appreciation for things that work perfectly, especially when they are designed to solve a single, critical problem. The fire adapter is a perfect example of this. It's not glamorous. It's not electronic. It's a piece of mechanical engineering that solves a fundamental problem of connection and compatibility. It doesn't need batteries, it doesn't need an update. It just needs to be the right size and be there when it's needed. Taking the half hour to identify, purchase, and test this device isn't just a smart chore; it's an act of responsible planning. You are proactively designing a solution for a potential failure point in your family's safety system. Make sure your guardian is ready.

Conclusion

A fire adapter is not an accessory; it is essential. This small, low-cost device solves the critical problem of hose incompatibility, ensuring firefighters can protect your home without delay.