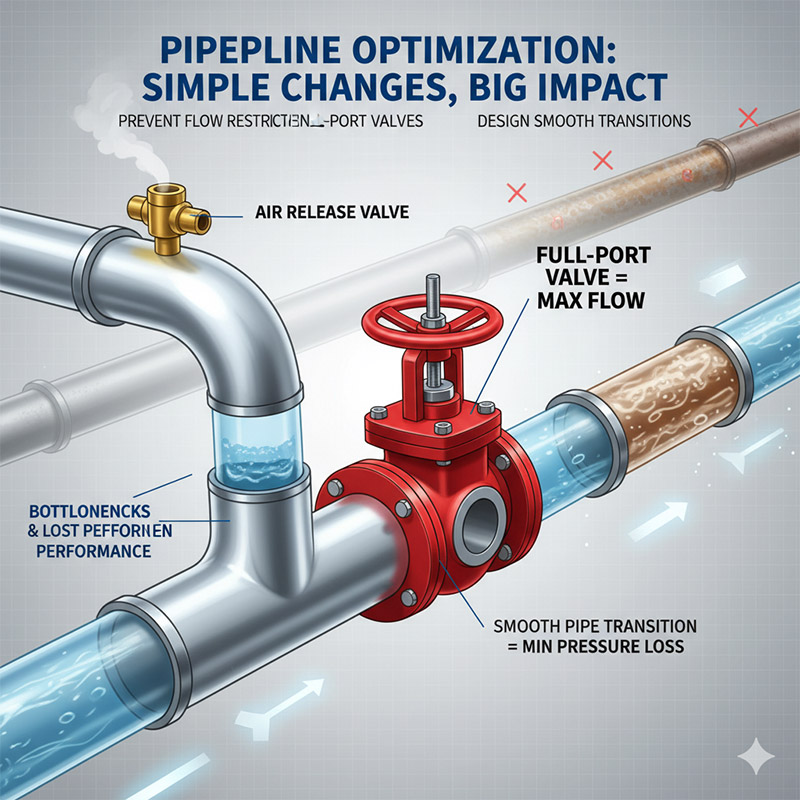

How Can You Make Your Pipeline System Work Better With Simple Changes?

Your pipeline has bottlenecks you can't see. These small inefficiencies are quietly costing you time and money in lost performance, slowly leading to bigger problems down the road.

Improve your system by placing air release valves at high points to prevent flow restriction, choosing full-port valves for maximum flow, and designing smooth pipe transitions to minimize pressure loss.

A client once called me about a major issue at their new plating facility. Their large cooling system, which was critical for maintaining the chemical baths at the correct temperature, was seriously underperforming. The pumps were supposedly oversized for the job, but the flow rate at the far end of the loop was pathetic. They were ready to rip out the pumps and buy even bigger ones. I asked them to wait and took a walk along the pipeline. What I found was a "death by a thousand cuts." They had used standard-port valves instead of full-port, numerous sharp 90-degree elbows where sweeping bends could have been used, and no air release valves at the highest point of the system. We didn't replace the pump. Instead, we spent a weekend making a few strategic component swaps. The result? The flow rate nearly doubled. This experience is a perfect lesson: a pipeline's performance is often lost in the small details, not in the big-ticket items.

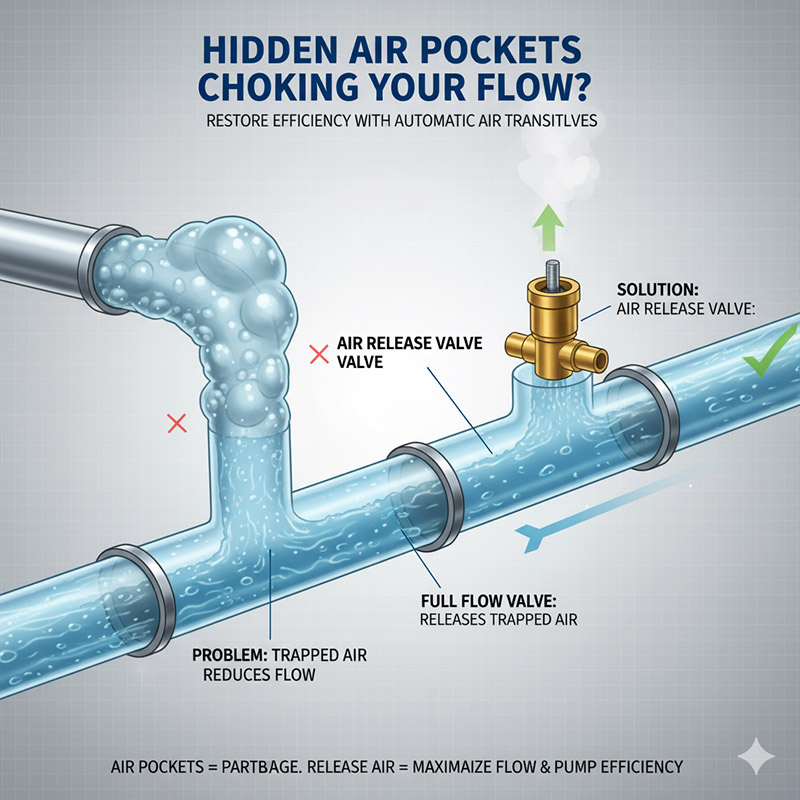

Are Hidden Air Pockets Silently Choking Your Pipeline's Flow Rate?

You're not getting the flow you expected from your pump. You have checked for blockages and leaks, but the poor performance persists, slowing down your entire process.

Yes, trapped air creates significant flow restriction, acting like a partial blockage. Installing automatic air release valves at the high points in your pipeline allows this trapped air to escape, restoring full flow and system efficiency.

Think about what happens when you have an air bubble in a clear drinking straw. The water has to fight its way around it. Now imagine that on a massive scale inside your pipe. Water cannot easily compress or push air out of the way. When air gets trapped at a high point in a pipeline, it forms a large, stubborn bubble. This bubble effectively reduces the internal diameter of the pipe at that point, sometimes drastically. This phenomenon is often called an "air lock." Your pump now has to work much harder to force the fluid past this restriction, leading to a major drop in flow rate and pressure downstream. As you know from designing parts, Jacky, an unplanned restriction can ruin a product's function. The solution is surprisingly simple: installing an automatic air release valve at these high points gives the air an easy way out, allowing the liquid to flow freely.

What is an Air Lock?

An air lock is a pocket of trapped air that obstructs liquid flow. In a pipeline, this typically occurs at peaks or high points where the air naturally congregates and has no escape route. The pump may not have enough pressure to force this air bubble down and out of the system.

Strategic Placement is Key

These valves are not installed randomly. You must identify the "summits" in your pipeline layout. This includes any upward loops or high horizontal runs where air will collect. Placing a valve there provides maximum benefit for minimal cost.

| Feature | System Without Air Valve | System With Air Valve |

|---|---|---|

| Flow Rate | Reduced and inconsistent | Maximized and stable |

| Pump Strain | High; pump works harder | Normal; efficient operation |

| Priming Issues | Pump may struggle to prime | System primes easily |

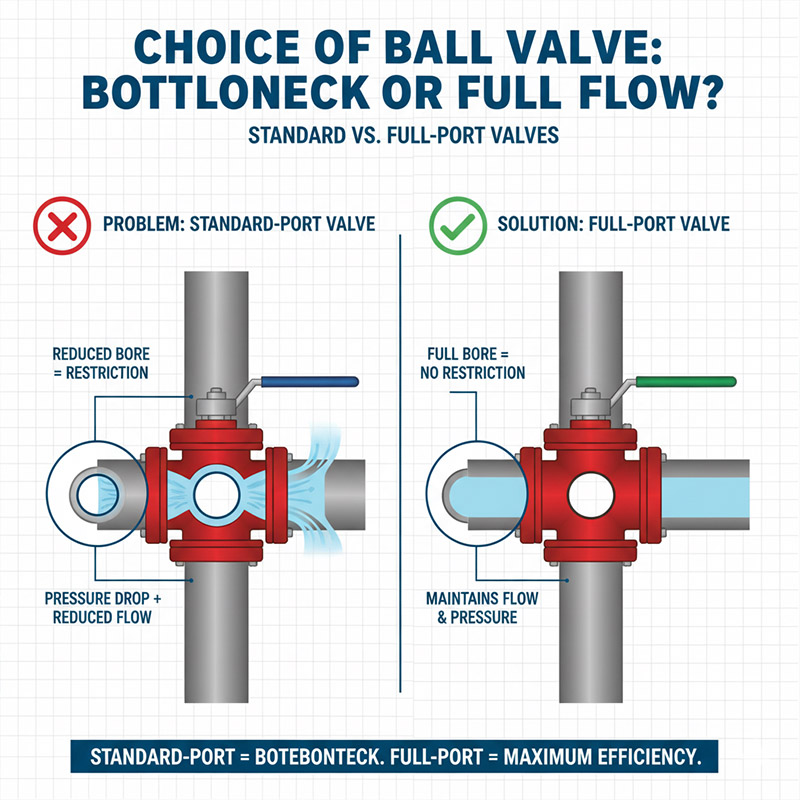

Is Your Choice of Ball Valve Secretly a Bottleneck?

You need to control a line, so you install a standard ball valve. But now, the pressure and flow downstream have dropped significantly, creating problems for your process.

It very well could be. A standard-port ball valve has a smaller hole than the pipe's inner diameter, creating a major restriction. Choosing a full-port valve ensures the opening matches the pipe, maintaining flow and minimizing pressure drop.

This is one of the most common and easily avoidable mistakes I see. A "2-inch standard-port ball valve" does not have a 2-inch hole through the ball. The hole might be 1.5 inches or even smaller. When your fluid, which has been flowing smoothly in a 2-inch pipe, suddenly has to squeeze through this smaller opening, you create turbulence and a significant pressure drop. It's like pinching a garden hose. The water sprays out faster, but the total volume of flow goes down. For a designer like you who thinks about efficiency, this is a critical detail. A full-port (or full-bore) valve is designed so that the hole in the ball is the same size as the pipe's internal diameter. When open, it's like a continuous piece of pipe. It offers almost no resistance to flow, preserving the pressure and energy your pump has worked so hard to create.

Visualizing the Restriction

Imagine your pipeline is a three-lane highway. A full-port valve keeps all three lanes open. A standard-port valve suddenly closes one of those lanes, causing a traffic jam and slowing everything down.

When to Choose Full-Port

Use full-port valves in any application where maintaining flow rate and minimizing pressure drop is critical. This is especially true on the main lines coming directly from your pump or in systems where you need to move high volumes of fluid efficiently.

| Valve Type | Port Diameter | Pressure Drop | Best Use Case |

|---|---|---|---|

| Full-Port | Matches pipe's inner diameter | Very Low | Main lines, high-flow applications |

| Standard-Port | Smaller than pipe's inner diameter | Moderate to High | Throttling, non-critical flow areas |

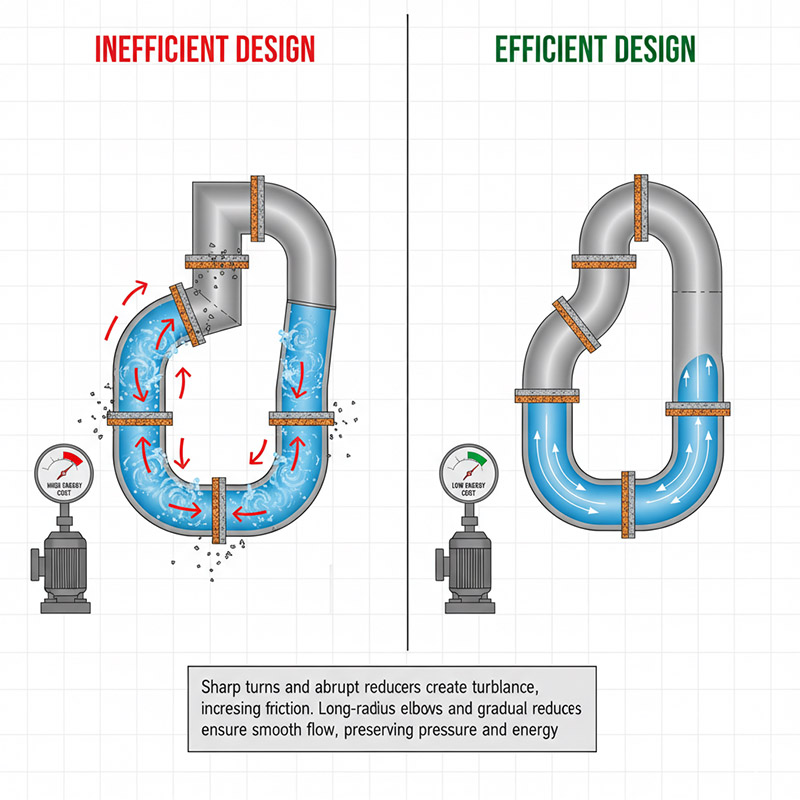

Can Sharp Turns and Abrupt Reducers Be Robbing Your System of Energy?

Your pipeline design includes several sharp 90-degree elbows and sudden pipe size changes. Now your pump's energy costs are higher than calculated, and you're seeing erosion at the joints.

Absolutely. Sharp bends and abrupt transitions create significant turbulence. This chaotic flow increases friction, forcing the pump to work much harder. Using long-radius elbows and gradual reducers creates smooth flow, preserving pressure and energy.

Fluid, like anything with mass, prefers to move in a straight line. When you force it to make a sharp 90-degree turn, it slams into the outer wall of the fitting. This creates a chaotic, swirling mess called turbulent flow. This turbulence is a huge energy thief. All that swirling and churning dissipates the energy your pump put into the fluid. The smooth, layered flow you want, called laminar flow, is disrupted. It's the difference between a race car taking a wide, sweeping turn versus trying to make a hairpin turn at full speed. As a designer, you know that smooth, aerodynamic shapes are more efficient. The same principle applies inside your pipes. By using long-radius elbows instead of standard ones, and tapered reducers instead of abrupt bushings, you guide the fluid gently, maintaining laminar flow and saving a surprising amount of energy.

Laminar vs. Turbulent Flow

- Laminar Flow: Smooth, efficient, and layered. The fluid moves in parallel paths. This is the ideal state for preserving energy.

- Turbulent Flow: Chaotic, swirling, and inefficient. It creates friction and pressure loss, and can even cause erosion over time.

Smart Design for Smooth Flow

Always think about the fluid's path. Every sharp turn is a source of energy loss. While standard elbows are cheaper and easier to package, the long-term energy savings from using sweeping bends often provides a very fast return on investment.

| Component | Flow Characteristic | Impact on System |

|---|---|---|

| Standard 90° Elbow | Creates high turbulence | High pressure loss, potential for erosion |

| Long-Radius Elbow | Maintains smoother flow | Low pressure loss, protects the system |

| Abrupt Reducer | Creates turbulence and a "jet" effect | High pressure loss, inefficient |

| Tapered Reducer | Gradual change, maintains laminar flow | Minimal pressure loss, very efficient |

Conclusion

Small, smart changes to your pipeline have a huge impact. By optimizing for flow with air valves, full-port valves, and smooth transitions, you will save energy and improve performance.