How Do We Prove Our Valves and Fittings Will Perform Flawlessly?

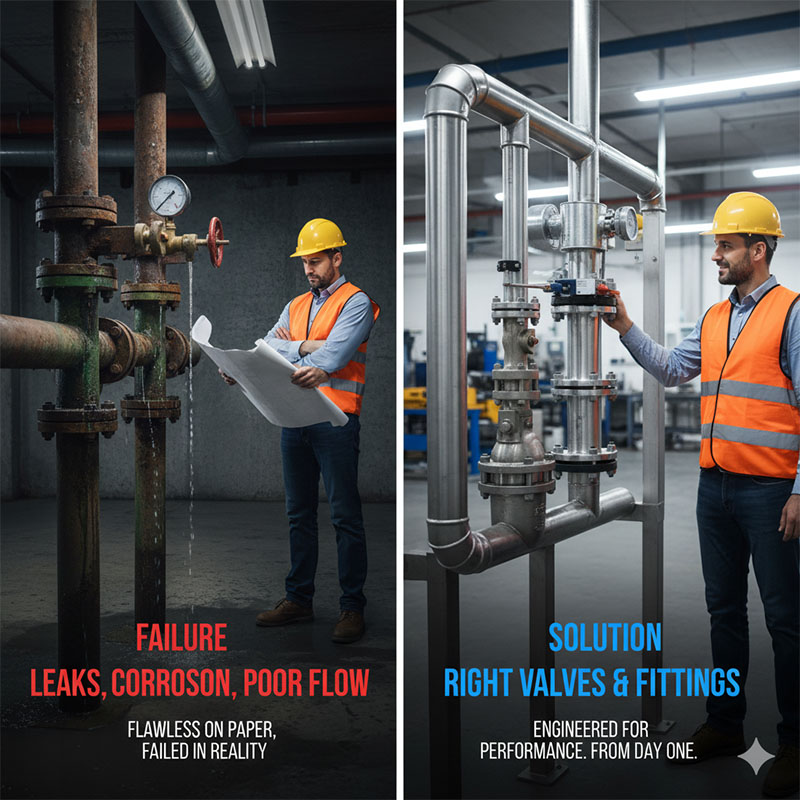

You've approved the design, but will it perform under pressure? A hidden flaw in a finished part can cause a catastrophic field failure, destroying your product's reputation.

We prove performance with a rigorous three-part validation process. We confirm every dimension with CMM technology, ensure all sealing surfaces are flawless, and subject every valve to a pressure test that exceeds its operational rating.

I once had a client, an excellent engineer, tell me something I've never forgotten. He said, "Mike, the part isn't finished until the test report is signed." He was absolutely right. A component without objective proof of its quality is just a well-shaped piece of metal. It's an unknown quantity. For a professional like you, unknowns are unacceptable. You need data. You need certainty. So let me walk you through the three tests we run on our valves and fittings to give you that absolute proof of performance.

How Can You Be Sure a Part Perfectly Matches the CAD Model?

A machinist's caliper says a part is "good," but tiny deviations stack up. This causes friction during assembly, delays on the production line, and inconsistent product performance.

We eliminate all guesswork by using a Coordinate Measuring Machine (CMM). This automated system measures parts against your CAD model with micron-level precision, providing a detailed report as proof.

In any machine shop, you'll see operators using digital calipers. They are great tools for quick checks on the factory floor. But for final validation of a critical component, they are not enough. The way an operator holds the caliper can slightly change the reading. That's why the heart of our quality lab is the Coordinate Measuring Machine, or CMM. Think of it as an incredibly precise robotic finger. We place your finished part on a granite slab, and its automated probe gently touches hundreds of specific points on the part. It compares these physical measurements directly against your original 3D CAD file. The CMM then generates a comprehensive report showing any deviation, often measured in millionths of an inch. This gives you a data-driven "digital twin" of the physical part, proving it's a perfect match to your design.

The Data of Dimension: Proving the Fit

-

### The Caliper vs. The CMM While calipers are essential for in-process checks, the CMM is our tool for final certification. It removes human variability and provides a far higher degree of accuracy and repeatability.

-

### Creating the Digital Proof The CMM report is your guarantee. It's a detailed, color-coded map showing that every critical diameter, hole position, and geometric tolerance is exactly where it should be.

| Inspection Method | Manual (Calipers) | Automated (CMM) |

|---|---|---|

| Accuracy | Good (Relies on operator skill) | Exceptional (Micron-level) |

| Repeatability | Varies by operator | 100% consistent |

| Data Output | Manual entry | Detailed digital report |

What Hidden Flaws on a Surface Can Cause Leaks?

An O-ring seal looks perfect when you assemble a product. But a microscopic scratch on the metal surface acts like a tiny knife, causing a slow leak weeks or months later.

We inspect and validate every sealing surface to be flawless. We use profilometers to measure smoothness and perform meticulous inspection to eliminate the microscopic flaws that cause seal failure.

This is one of the most overlooked areas of quality control, and it's where most failures begin. A part can be dimensionally perfect, but if the surface where a seal sits is even slightly too rough, it will fail. Why? Metal surfaces, even smooth ones, have microscopic peaks and valleys. If the peaks are too sharp, they can chew up a rubber O-ring. Worse yet, a "burr"—a tiny, sharp edge left over from machining—can slice a seal instantly. We combat this in two ways. First, we use a profilometer. This instrument drags a diamond-tipped stylus across the sealing surface to measure its roughness (Ra value) and ensure it meets your specification. Second, every part undergoes careful deburring and visual inspection under magnification to guarantee it is free of any sharp edges. This ensures a perfect, leak-proof seal for the life of your product.

The Science of Smoothness: Preventing Leaks

-

### The Danger of the Microscopic Burr Consider a burr to be a razor blade. It's the number one enemy of any seal. Our process is designed to hunt down and eliminate every single one.

-

### Measuring Smoothness A profilometer gives us a number—the surface roughness average (Ra)—that tells us if the surface is smooth enough to create a reliable, long-lasting seal.

| Risk Factor | Standard Finish | Our Validated Surface |

|---|---|---|

| Burrs | Often left by automated tumbling. | Removed by targeted deburring. |

| Roughness | Assumed to be "good enough." | Measured and verified with a profilometer. |

| Contaminants | May have residual oils/fines. | Surgically clean from ultrasonic baths. |

How Do You Really Know a Valve Won't Leak Under Pressure?

You install a new valve and assume it will hold. But a tiny, invisible flaw from the casting process or an error in assembly causes it to fail in the field.

We don't assume; we prove it. Every single assembled valve is subjected to a hydrostatic pressure test at 1.5 times its maximum working pressure to guarantee it is 100% leak-free.

This is the final exam for every valve we build, and it's a test with no partial credit. A valve either passes or it fails. Many manufacturers use "batch sampling." They'll pull one valve out of a hundred and test it, assuming the other 99 are identical. This is a risk we are not willing to take, and neither should you. Our policy is 100% hydrostatic testing. We connect every valve to a test bench, fill it with water, and use a pump to raise the internal pressure to 150% of its official rating. We then hold that pressure and our technicians, along with pressure-drop sensors, check for any leaks, no matter how small. This process provides absolute certainty that the valve's body is sound, the seals are working, and the assembly is perfect. It's the ultimate proof that the valve will perform for you in the real world.

The Ultimate Proof: Real-World Performance Testing

-

### The Problem with "Good Enough" Sampling Sampling means accepting a certain level of risk. A 1% failure rate is acceptable in sampling, but if you have that one failed part, it's a 100% failure for you.

-

### The 100% Test Guarantee By testing every single unit, we replace statistical probability with absolute certainty. You know for a fact that the specific valve you hold in your hand has been tested and passed.

| Testing Philosophy | Batch Sampling | 100% Hydrostatic Testing |

|---|---|---|

| Goal | Ensures the batch is likely okay. | Ensures your specific part is perfect. |

| Risk to You | A small but real chance of failure. | Zero chance of receiving an untested part. |

| Confidence Level | Statistical confidence. | Absolute, documented confidence. |

Conclusion

Dimensional data, surface validation, and pressure testing are our promises to you. They are the proof that every component we ship is ready to perform exactly as you designed it.