Do Your Mold Sight Glasses Really Need Special Maintenance?

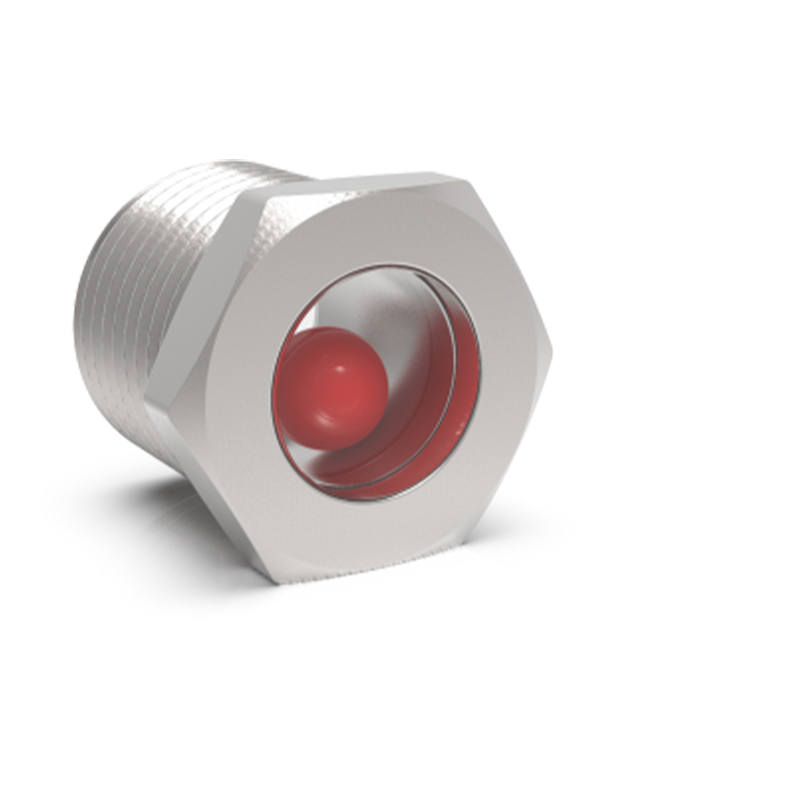

You installed them on every cooling line. Now you just glance at them, trusting the little spinners or floating balls. But are you ignoring a ticking time bomb?

Yes, they require specific maintenance. This maintenance is not difficult but is crucial for accuracy and safety. It involves regular cleaning to prevent buildup, checking seals to stop leaks, and verifying the internal mechanisms haven't been compromised by debris.

This reminds me of a visit to a high-volume cap and closure molder. They had one 96-cavity mold that was consistently producing about 5% scrap, always from the same quadrant of the tool. The process tech was stumped. The cooling manifold had flow indicators for every zone, and all of them read a healthy 4 gallons per minute. Everything looked perfect on paper. I asked him, "When was the last time you cleaned these?" He gave me a blank look. We pulled one of the "good" indicators from the problem quadrant. When we held it up to the light, we saw a hazy film of mineral scale coating the inside of the viewing tube. This film was just thick enough to make the floating ball "stick" at a high reading, even when flow was restricted. The maintenance they skipped wasn't a complex rebuild; it was a simple cleaning that would have saved them weeks of chasing scrap.

How Do You Clean and Maintain Flow Indicators Without Damaging Them?

You know your flow indicators are getting grimy, but you're afraid to clean them. You’ve heard stories of people using the wrong chemical and watching the plastic turn foggy and crack.

This fear is valid, as improper cleaning can destroy an indicator. Using harsh solvents or abrasive brushes will cause permanent damage, rendering the indicator useless or causing it to fail under pressure.

The solution is to use gentle methods. Disassemble the indicator completely. Use warm water, a mild soap like dish soap, and a soft-bristle brush. For stubborn mineral scale, use a commercial descaler that is certified as safe for plastics like polycarbonate and polysulfone.

Let's dive deeper into a safe and effective cleaning protocol. The number one rule is to know what your indicator is made of. Most are polycarbonate, polysulfone, or acrylic. Aggressive industrial degreasers, acetone, or brake cleaner will instantly cause crazing—a network of fine cracks—and make the plastic brittle. Always check the manufacturer's chemical compatibility chart if you are unsure. When it comes to mechanical cleaning, never use a wire brush or metal scraper. These will scratch the interior viewing surface, making it hard to read and creating spots where debris can collect in the future. A soft nylon bottle brush is your best friend. For reassembly, make sure the O-rings or flat gaskets are clean, pliable, and correctly seated. A tiny bit of silicone O-ring lubricant can help ensure a good seal and make future disassembly easier.

A Safe Cleaning Protocol

| Step | Action | Why It's Important |

|---|---|---|

| 1. Disassemble | Carefully take the indicator completely apart. Note the order of the components. | Allows you to clean every surface and inspect individual parts like O-rings and floats. |

| 2. Gentle Wash | Wash all parts in warm, soapy water using a soft brush. | Removes common grime and biofilm without damaging the plastic or scratching the see-through surfaces. |

| 3. Descale (If Needed) | Soak in a plastic-safe descaling solution according to the manufacturer's directions. | Dissolves hard water mineral deposits (calcium, lime) that cause parts to stick, without attacking the plastic body. |

| 4. Rinse & Dry | Rinse all parts thoroughly with clean water and let them air dry completely or use compressed air. | Removes any remaining soap or descaler residue that could contaminate your cooling system. |

| 5. Inspect & Reassemble | Check O-rings for cracks. Ensure floats or spinners move freely. Reassemble carefully. | This is your final quality check to prevent leaks or immediate failure upon reinstallation. |

What Is the 'Preventive' Maintenance That Matters Most?

You're tired of constantly reacting to problems. You clean an indicator, and a month later it's clogged again. You wonder if there's a better way than just cleaning up messes.

Yes, the best maintenance is proactive, not reactive. The most critical "maintenance" for a flow indicator happens outside the indicator itself, in the system that feeds it.

The most effective preventive action is installing proper filtration before the coolant enters the indicator. A 50-100 micron filter will catch the rust, scale, and sediment that cause 90% of indicator failures, dramatically extending their life and reliability.

Let's break down the layers of prevention. Filtration is your first and strongest line of defense. Think of it as protecting your investment. You wouldn't run an engine without an oil filter; don't run a cooling manifold without a water filter. This single step prevents the internal mechanisms—the ball, spinner, or piston—from getting jammed with debris, which is the primary cause of false readings. The second layer of prevention is your water quality. If you are running in an open-loop system with untreated water, you are fighting a losing battle. A closed-loop system with properly treated water (containing rust inhibitors and biocides) will keep the entire system clean, from the chiller to the indicator. Finally, there's the simple act of regular observation. Make it part of the operator's daily checklist to visually inspect all indicators. Are they cloudy? Are there any drips? Is a ball in a low-flow circuit suspiciously high? Catching these small visual cues early prevents a small issue from becoming a production-stopping failure.

Key Preventive Maintenance Actions

| Preventive Action | Frequency | Impact on Indicator Life |

|---|---|---|

| Install/Clean Upstream Filter | Check weekly, clean/replace as needed. | High. Prevents >90% of internal jams and sticking. |

| Monitor Water Quality | Test monthly or per facility protocol. | High. Prevents internal scale buildup and chemical attack on plastics. |

| Visual Inspection | Daily / at the start of each shift. | Medium. Catches early signs of leaks, clouding, or failure before they cause downtime. |

| Check for Leaks | Daily. Pay attention to thread connections. | Medium. Prevents catastrophic failure from cracked housings due to over-tightening. |

Conclusion

True sight glass maintenance is about prevention. By filtering your coolant and performing simple, regular cleanings, you ensure your indicators provide the accurate data you need to run a stable and profitable molding process.