Hydronic heating and cooling systems are widely used in modern commercial and residential buildings for their efficiency, scalability, and comfort. However, achieving hydraulic balance across various circuits and terminal units can be a significant challenge—especially in variable flow systems where loads change dynamically.

One proven solution to this challenge is the use of Differential Pressure Control Valves (DPCVs), also known as Pressure Balancing Valves. These valves play a vital role in maintaining system stability, enhancing energy efficiency, and simplifying system commissioning.

Understanding Differential Pressure Control Valves

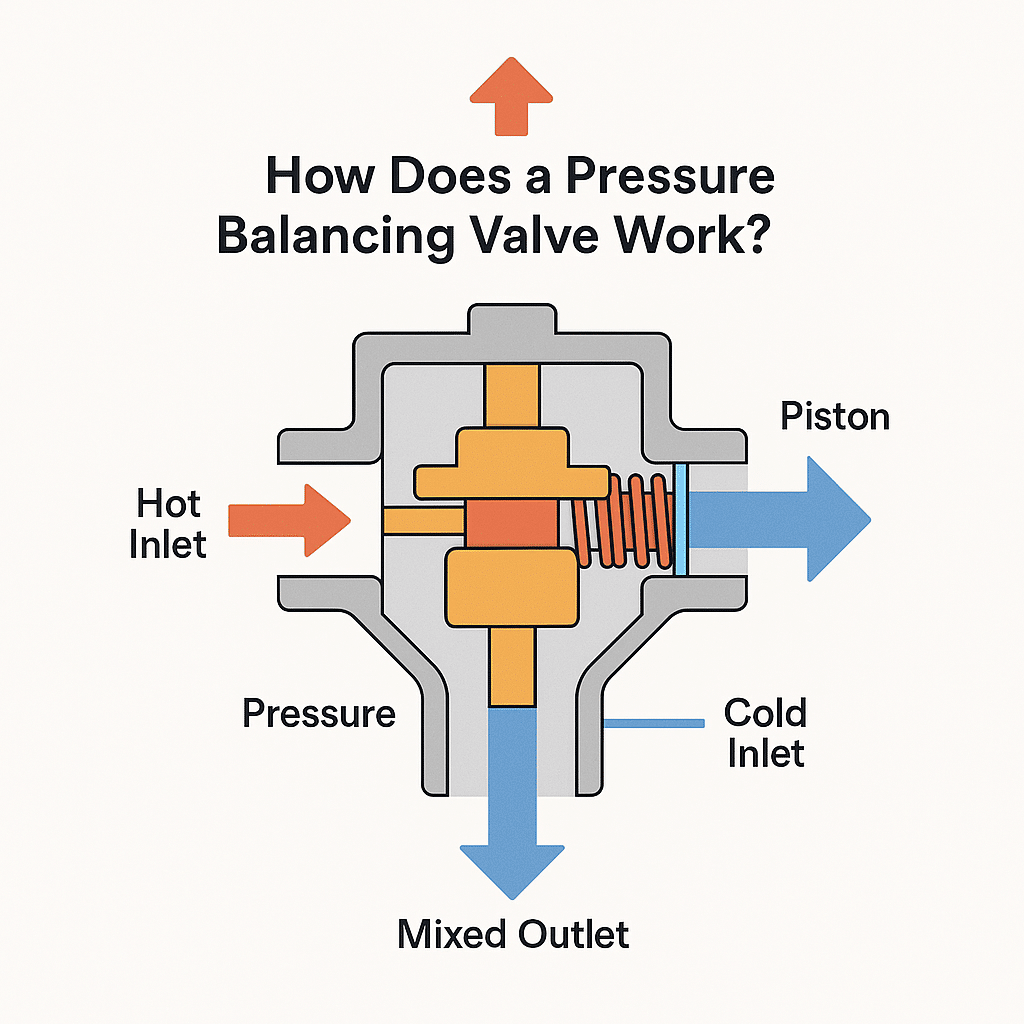

A Differential Pressure Control Valve is designed to automatically maintain a constant pressure differential across a defined section of a hydronic circuit, such as a fan coil unit, floor heating loop, or zone valve branch. This constant pressure ensures that control valves operate within their optimal range and that each terminal unit receives its design flow rate—even under partial load or fluctuating conditions.

In technical discussions, the term Pressure Balancing Valve is often used interchangeably with DPCV, reflecting the valve’s core function of hydraulic balancing through pressure regulation.

Technical Benefits of DPCVs

Incorporating DPCVs into hydronic systems brings several engineering and operational advantages:

-

Stabilized Control Valve Operation

By keeping the differential pressure across terminal control valves constant, DPCVs prevent valve hunting, improve modulation accuracy, and reduce system noise. -

Improved Energy Efficiency

When the pressure across branches is regulated, the required pump head can be reduced. This minimizes over-pumping and contributes to lower energy consumption. -

Simplified Commissioning

Unlike manual balancing valves, DPCVs automatically adapt to changing flow conditions, significantly reducing the time and complexity of commissioning work. -

Enhanced Comfort and Zoning Accuracy

Stable flow to each zone results in more precise temperature control and improved occupant comfort, particularly in large buildings with diverse usage patterns.

Product Application: Fanovo 3/4” BSP DZR Brass DPCV

Fanovo’s 3/4” BSP DZR Brass Differential Pressure Control Valve is engineered for reliability and durability in demanding hydronic environments. Constructed from dezincification-resistant (DZR) brass, it is ideal for use in closed-loop HVAC systems where water chemistry or operational stress may compromise conventional brass valves.

Key technical characteristics include:

-

Automatic pressure differential regulation

-

Corrosion-resistant DZR brass construction

-

Integrated on/off control functionality

-

Compact design for easy installation in limited space

-

Suitable for both heating and cooling applications

This valve is particularly well-suited for use in fan coil systems, radiant floor heating, and terminal circuits in district heating and cooling networks.

Installation and Operating Guidelines

To ensure optimal performance, the DPCV should be installed on the return side of the controlled circuit, with attention to flow direction as indicated on the valve body. The valve’s spring mechanism should be pre-set or adjusted to match the designed differential pressure requirements.

When installed correctly, the valve continuously modulates to maintain stable pressure conditions across the connected terminal device or zone. This ensures that design flow rates are achieved without the need for manual adjustment during commissioning.

Typical Use Cases

DPCVs are widely applied in various hydronic system configurations, including:

-

Multi-zone commercial fan coil systems

-

Underfloor heating systems in residential buildings

-

Terminal branches in chilled water and hot water distribution networks

-

Decentralized district energy systems requiring pressure regulation across branches

Conclusion

Differential Pressure Control Valves—also known as Pressure Balancing Valves—are a critical component in modern HVAC system design. They contribute to improved energy performance, simplified commissioning, and more consistent comfort by actively maintaining hydraulic balance throughout the system.

Fanovo’s DZR Brass DPCV provides a high-quality, long-lasting solution for engineers and contractors looking to optimize flow control and pressure regulation across their hydronic networks.