In industrial and commercial fluid control systems, pressure balancing valves are critical for maintaining stable flow rates, temperature control, and system safety. While often linked to residential plumbing, these valves are indispensable in demanding environments like chemical processing, HVAC systems, and water treatment plants.

This guide covers:

-

How pressure balancing valves work

-

Key industrial applications

-

Benefits for efficiency and safety

-

Why Fanovo’s engineered valves stand out

Related: The Role of Differential Pressure Control Valves

What Is a Pressure Balancing Valve?

A pressure balancing valve (or pressure regulator valve) is a mechanical device that equalizes fluctuating inlet pressures—typically between hot and cold fluids—to deliver a consistent output pressure and temperature. It prevents:

✔ System shock from sudden pressure changes

✔ Equipment stress caused by hydraulic surges

✔ Safety risks in temperature-sensitive processes

Common Uses:

-

Industrial piping systems

-

HVAC and cooling circuits

-

Pharmaceutical manufacturing

-

Water treatment and pumping stations

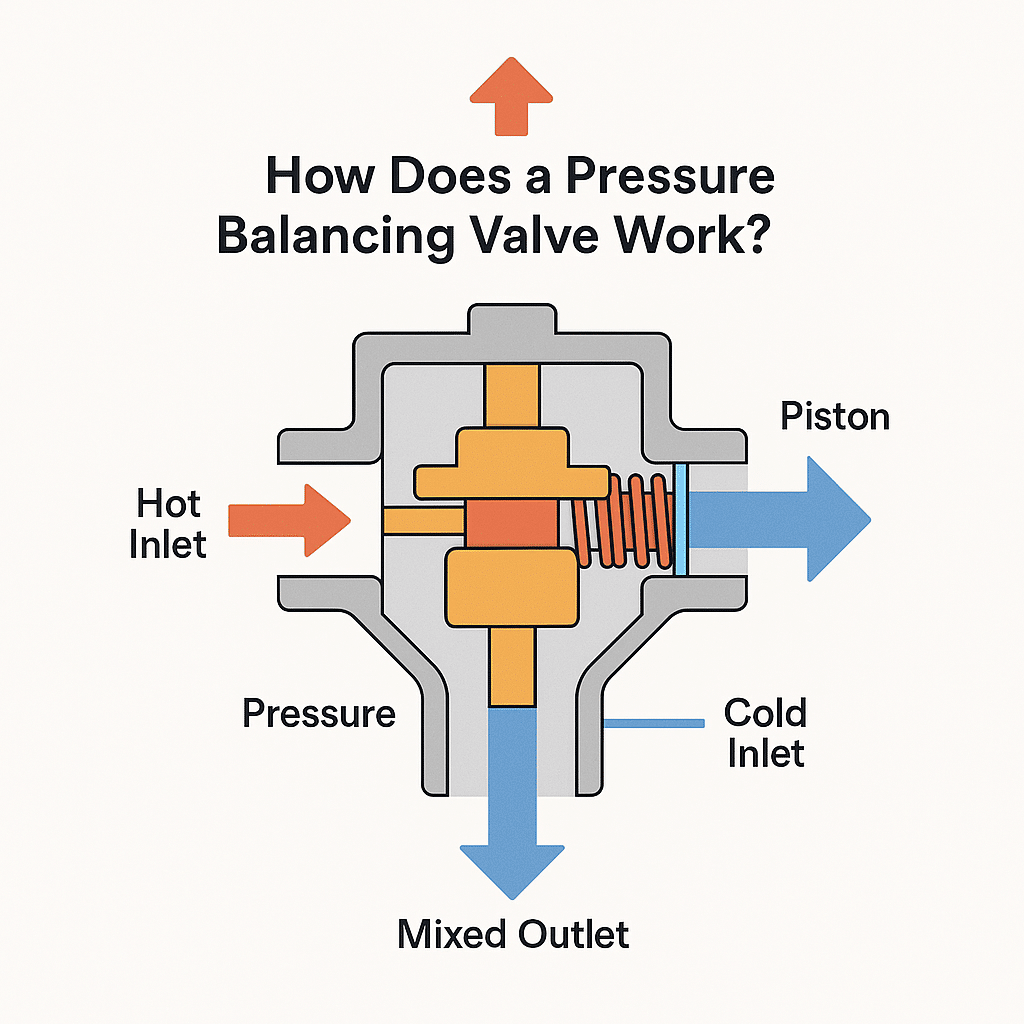

How Does a Pressure Balancing Valve Work?

Pressure balancing valves rely on a piston, diaphragm, or spring mechanism to auto-adjust flow rates. Here’s the process:

-

Inlet Pressure Detection

-

The valve monitors hot and cold fluid inlets (or dual pressure lines).

-

-

Automatic Adjustment

-

If one side’s pressure drops (e.g., cold water surge), the internal mechanism reduces flow on the opposite side (hot water) to maintain balance.

-

-

Stable Output Delivery

-

Outlet pressure and temperature remain constant despite upstream fluctuations.

-

Key Mechanism Types:

-

Piston-Based: Durable for high-pressure industrial systems.

-

Diaphragm-Operated: Precise for sensitive applications (e.g., pharmaceuticals).

Related: What is Custom Valve Manufacturing

Industrial Applications of Pressure Balancing Valves

1. Chemical & Pharmaceutical Manufacturing

-

Maintains exact fluid temperatures for reactive processes.

2. HVAC and Cooling Systems

-

Prevents heat exchanger damage from pressure spikes.

3. Food & Beverage Processing

-

Ensures consistent steam/water delivery for sanitation.

4. Water Distribution Networks

-

Protects pipelines from hydraulic shock (water hammer).

5. Marine/RV Systems

-

Compact valves regulate limited water supplies onboard.

5 Benefits of Pressure Balancing Valves

-

Equipment Protection – Shields pumps, boilers, and sensors from surge damage.

-

Energy Efficiency – Reduces wasted fluid/energy in unbalanced systems.

-

Safety Compliance – Critical for OSHA-regulated environments.

-

Lower Maintenance Costs – Minimizes wear from pressure fluctuations.

-

User Comfort – Stable temperatures in hotels, hospitals, and labs.

Why Choose Fanovo Pressure Balancing Valves?

Fanovo’s industrial-grade valves are engineered for reliability under extreme conditions:

-

Materials: Corrosion-resistant brass/stainless steel.

-

Testing: Rigorous ISO-certified performance checks.

-

Custom Solutions: Valves tailored to your system’s PSI, temperature, and flow needs.

Pro Tip: Pair with a thermostatic mixing valve for precise temperature control in critical processes.

Need Expert Help Selecting a Valve?

Fanovo’s engineers can recommend the ideal pressure balancing valve for your application. Contact us today for a free consultation.