What Is a Boiler Drain Valve Actually Used for on Your Molding Equipment? You need a quick mold change. The temperature control unit is full of hot, pressurized water, making the process slow and dangerous. How do you drain it eff

How Do You Know if Your Mold’s Bypass Valve is Open or Closed? Your mold temperature is unstable, causing defects. You suspect a flow issue, but the chiller seems fine. Is a hidden valve sabotaging your entire process? To tell if

Should Your Chiller’s Sight Glass Go Before or After the Filter-Drier? You’re desperately trying to fix a chiller that isn’t cooling your mold properly. The sight glass looks clear, but you still suspect there’s a problem with the

How Does an Industrial Float Valve Keep Your Chiller Tank from Running Dry? The emergency alarm sounds. Production halts. The problem isn’t the mold or the machine, but an empty chiller tank that has starved your entire facility o

Do Your Mold Sight Glasses Really Need Special Maintenance? You installed them on every cooling line. Now you just glance at them, trusting the little spinners or floating balls. But are you ignoring a ticking time bomb? Yes, they

Should You Use Stainless Steel or Brass Fittings for Your Mold Cooling Lines? You’re tired of seeing messy, green corrosion on your mold’s cooling fittings. A tiny drip from a cheap fitting just caused a two-hour produ

What Are the Most Common Problems with Mold Flow Indicators? You’re pulling your hair out over a mysterious quality issue. The parts have sink marks, but only in one corner. You check the cooling manifold, and every flow ind

Should a Flow Indicator Go Before or After the Filter on a Mold? You’re battling inconsistent parts and hot spots on your mold. You suspect poor cooling, but your flow indicators say everything is fine. You’re losing time and mone

How Can You Guarantee Leak-Free Connections on Your Molds? You see it from across the shop floor: a tiny, persistent drip from a hydraulic line on your new mold. It seems minor, but it means constant cleanup, slip hazards, and unp

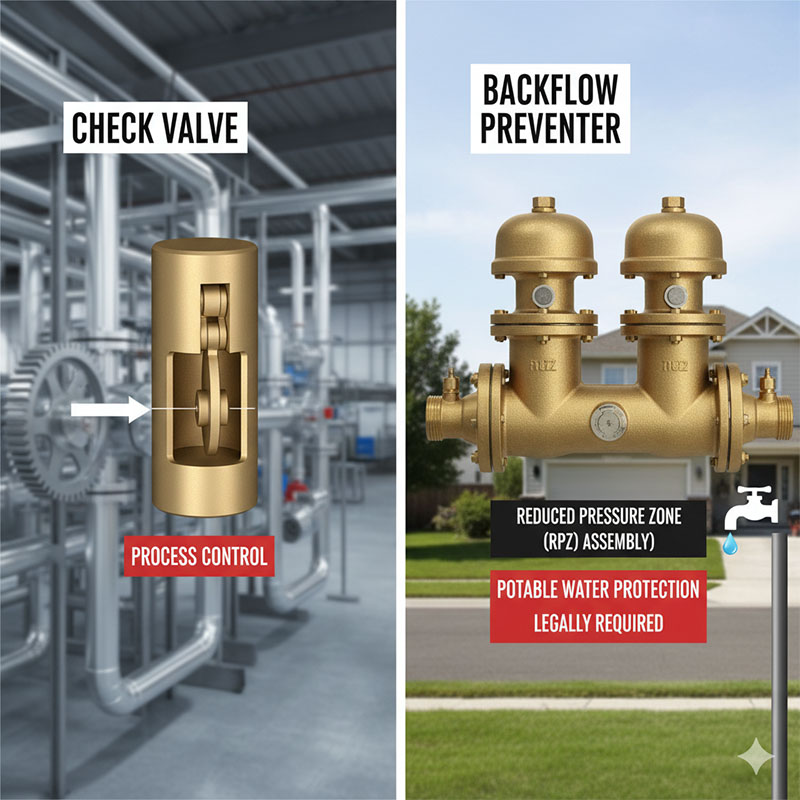

Are a Check Valve and a Backflow Preventer Actually the Same Thing? You hear the terms “check valve” and “backflow preventer” used on the factory floor, sometimes interchangeably. But you know there’s a critical, and potentially c

Gate Valve vs. Ball Valve: Which is Right for Your Garden Hose? You grab your garden hose, but the outdoor spigot is a nightmare. The handle is stiff, it takes a dozen turns to open, and when you finally shut it off, it still drip

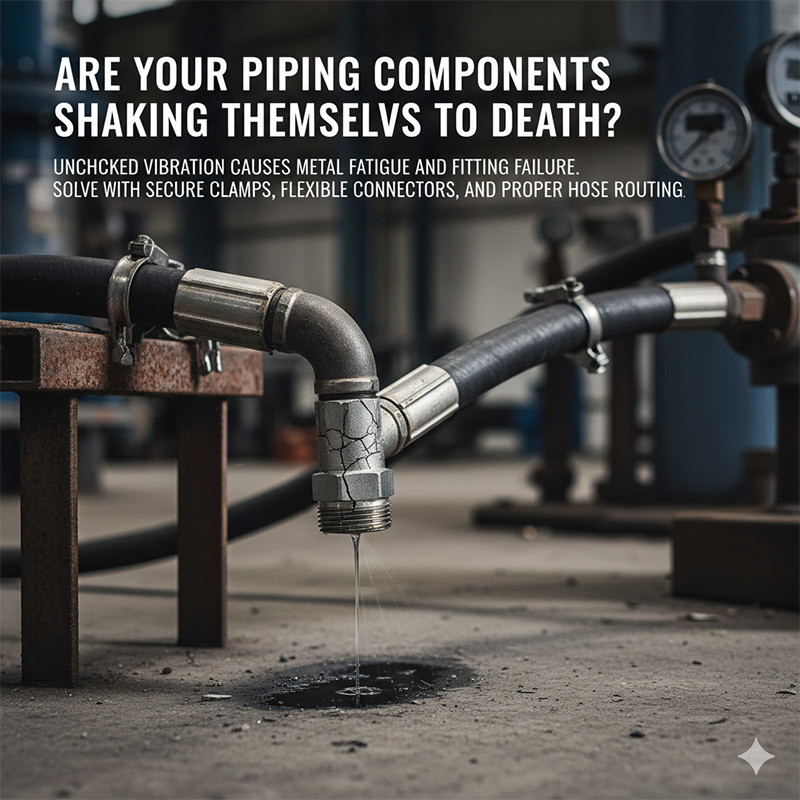

How Can You Double the Life of Your Mold’s Piping Components? Your high-performance mold is plagued by premature failures. Constant leaks from corroded or cracked piping components are causing frustrating downtime and eating into

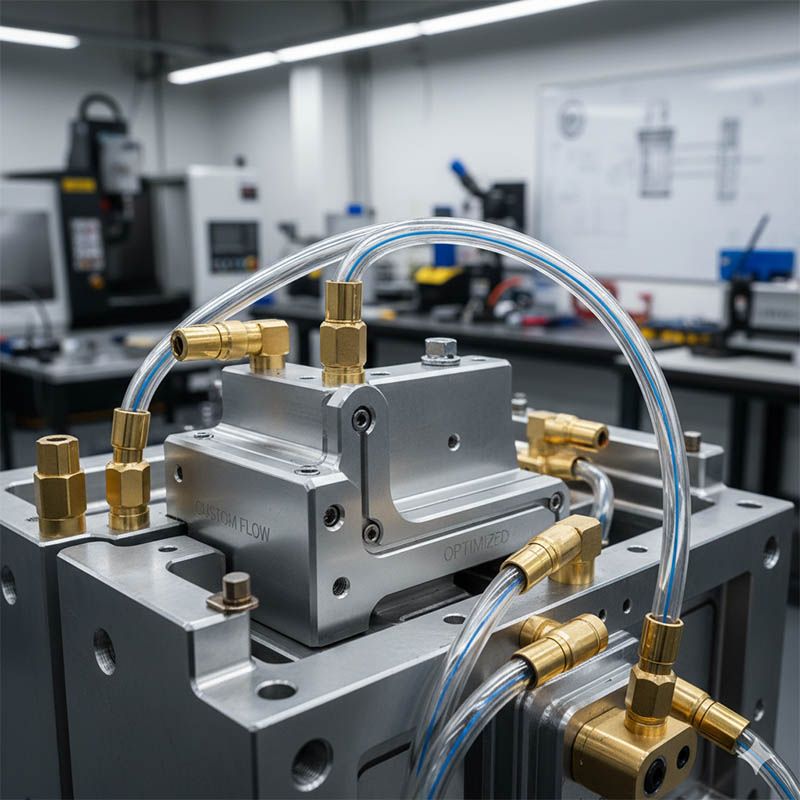

Is It Time to Design Your Own Custom Flow Control Parts? You’re stuck trying to plumb a complex mold. Standard fittings create clumsy hose routes, restrict flow, and introduce multiple potential leak points. The perfect solution s

Are Your Valves and Fittings a Maintenance Nightmare in Disguise? You’ve designed an innovative mold, but the maintenance team dreads working on it. Seemingly simple tasks like replacing a seal take hours, causing production

Are Your Valves and Fittings Secretly Sabotaging Your Mold? You’ve spent weeks perfecting your mold design. But the humble valves and fittings are an afterthought. This mistake can lead to leaks, pressure drops, and catastrophic d

Is Your Steam Boiler a Gentle Giant or an Explosive Powerhouse? You design a brilliant piece of equipment that uses steam. You assume the steam supply from the wall is consistent and reliable. But it’s not. The problem isn’t your