Are You Risking Overpressure Accidents and Costly Downtime? Here's How Compliant Relief Valves Can Protect Your Plant.

An overpressure event can burst a pipe or vessel in an instant. This endangers workers, destroys equipment, and brings your entire production line to a grinding, expensive halt.

A compliant relief valve is your non-electrical, automatic line of defense. It's engineered to vent excess pressure safely before it reaches catastrophic levels, turning a potential disaster into a manageable, non-event.

As a plant manager, you have to worry about a hundred things at once. I get it. I remember walking through a partner's factory once and seeing a hydraulic power unit for a large press. The pressure gauge was vibrating violently in the red zone. I asked the operator about it, and he just shrugged, saying "it does that sometimes." We immediately shut it down. We discovered the relief valve was clogged with debris and completely seized. That simple, ignored valve was the only thing stopping a 3,000 PSI hydraulic line from exploding like a bomb in a busy work area. That day taught me that the smallest safety components require the biggest attention.

What Does "Compliant" Really Mean for a Relief Valve, and Why Should You Care?

You have relief valves installed, so you believe your plant is safe. But if they don't meet specific industry standards, you could face massive fines or have an insurance claim denied after an accident.

A compliant relief valve is certified to meet strict safety and performance standards from bodies like the American Society of Mechanical Engineers (ASME). This certification is your proof that it will perform reliably under pressure.

Think of compliance as a guarantee. It’s an assurance from a third party that the valve isn’t just a piece of metal, but a precision safety instrument that has been rigorously designed and tested. In the event of an accident investigation by a body like OSHA, having certified components is one of the first things they will look for. Non-compliance can be interpreted as negligence, and the consequences are severe. This isn't just about following rules; it's about protecting your people and your business with a device that is proven to work when everything else fails.

Key Elements of Valve Compliance

| Compliance Factor | Why It Is Critical for a Plant Manager |

|---|---|

| ASME Certification | The industry gold standard. It proves the valve's design and capacity. |

| Material Traceability | Confirms the valve is made from the right materials for your gas/liquid. |

| Set-Pressure Accuracy | Guarantees the valve will open at the specified pressure, not too early or too late. |

| Capacity Stamping | The valve is clearly marked with its flow capacity (CFM or GPM). |

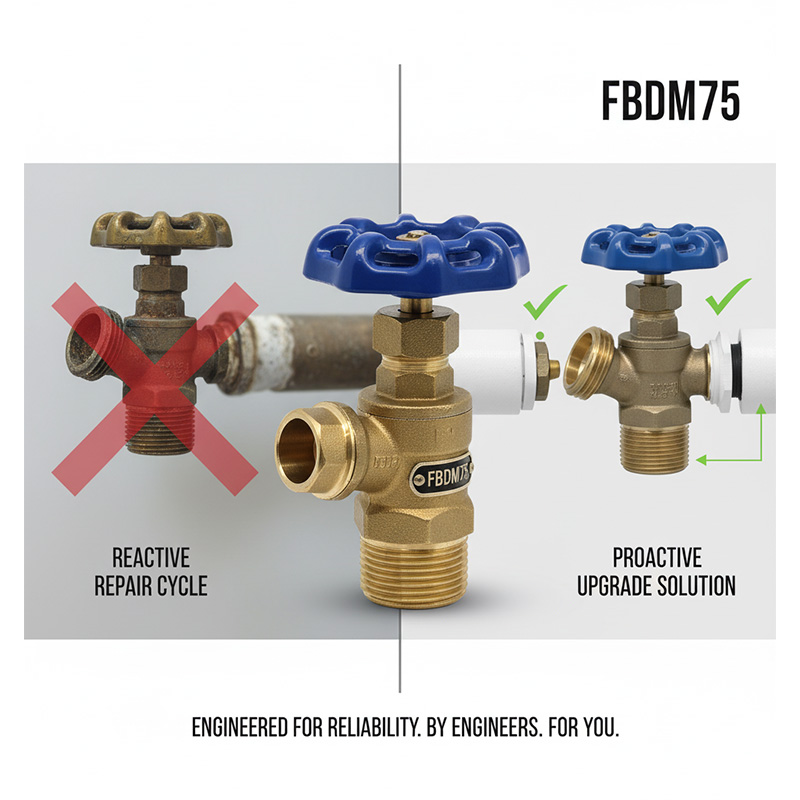

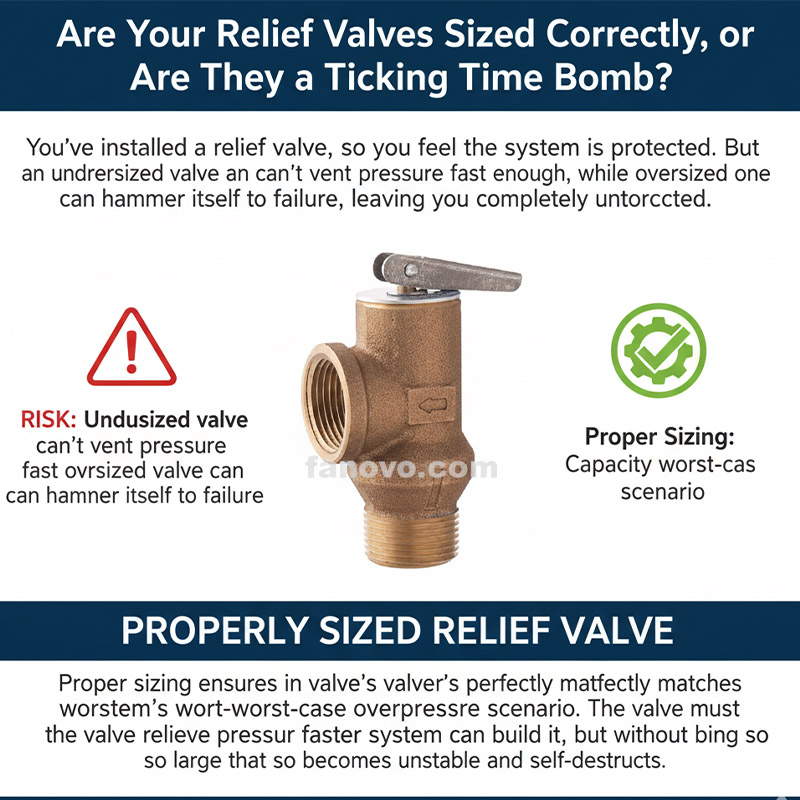

Are Your Relief Valves Sized Correctly, or Are They a Ticking Time Bomb?

You've installed a relief valve, so you feel the system is protected. But an undersized valve can't vent pressure fast enough, while an oversized one can hammer itself to failure, leaving you completely unprotected.

Proper sizing ensures the valve's capacity perfectly matches the system's worst-case overpressure scenario. The valve must relieve pressure faster than the system can build it, but without being so large that it becomes unstable and self-destructs.

Sizing a relief valve is not about matching the pipe size. It's a critical engineering calculation based on the maximum energy input of your system. An undersized valve is like trying to drain a flooding bathtub with a drinking straw; the water level will keep rising. The pressure will build until something ruptures. On the other hand, an oversized valve is also dangerous. It will open, vent a large amount of pressure very quickly, and slam shut. This rapid, violent opening and closing is called "chatter," and it will destroy the valve's internal seat in a short amount of time, causing it to fail. Getting the size right is absolutely essential for reliable protection.

The Dangers of Improper Sizing

- Undersized Valve: Fails to prevent overpressure. The system pressure continues to rise even with the valve open, leading to a rupture of the tank, pipe, or vessel. This is a catastrophic failure.

- Oversized Valve: The valve "chatters" by rapidly opening and closing. This hammering action damages the internal sealing surfaces, causing the valve to leak or fail to reseat properly after an event.

What Are the Hidden Costs of a "Set It and Forget It" Approach to Relief Valves?

Maintenance budgets are always tight, making it easy to skip testing relief valves. But internal corrosion, spring fatigue, or debris can cause a valve to seize shut, turning your safety device into a silent, catastrophic liability.

Neglecting relief valve maintenance creates hidden costs that are far greater than the price of a testing program. These include catastrophic failures, unplanned downtime, regulatory fines, and the immense cost of a workplace injury.

A relief valve is a mechanical device with a spring and a seal. It sits dormant, hopefully for years. But over that time, the spring can lose its tension, or the seal can become stuck to the seat from corrosion or process buildup. A valve that doesn't open is not a safety device at all; it's just a plug in your pipe. Regular testing is the only way to know if your last line of defense is actually ready. The cost of a testing program is a rounding error compared to the cost of even a minor overpressure incident.

The True Cost of a Failed Relief Valve

| Cost Category | Specific Financial Impacts |

|---|---|

| Direct Costs | Replacement of the valve and the ruptured equipment (vessel, pump). |

| Downtime Costs | Lost production, idle labor, paying overtime to catch up, missed deadlines. |

| Regulatory & Legal | Heavy OSHA fines, potential lawsuits, increased insurance premiums. |

| Human Costs | Medical expenses from injuries, and the tragic potential for a fatality. |

Conclusion

A compliant, correctly sized, and well-maintained relief valve is not an expense. It is essential insurance that actively protects your equipment, your people, and your plant’s bottom line every single day.