Why is a Simple Garden Faucet Fitting So Deceptively Complex?

That small brass fitting for your garden hose looks simple, but a cheap one just failed, causing a frustrating leak. You're annoyed by the wasted water and the product's poor quality.

The reliability of a fitting that lasts for decades comes from hidden craftsmanship. It’s a combination of choosing solid brass, using high-precision CNC machining, and performing rigorous quality testing on every part.

When you turn on the garden tap on a warm day and see that clean, steady stream of water, you probably don't think about much beyond the task at hand. Just last week, I was replacing a cheap plastic vacuum breaker on my own hose bibb that had cracked after just one winter. The failure reminded me of the stark difference between something designed to just be sold and something engineered to last. The replacement I bought was a heavy, solid brass fitting. To most people, it's just a small piece of metal. But for someone like me, who has spent a lifetime on factory floors, I see a story in that part. I see the material science, the machining precision, and the human oversight that came together to create something you can truly depend on. Let's break down what really goes into making a part you can trust.

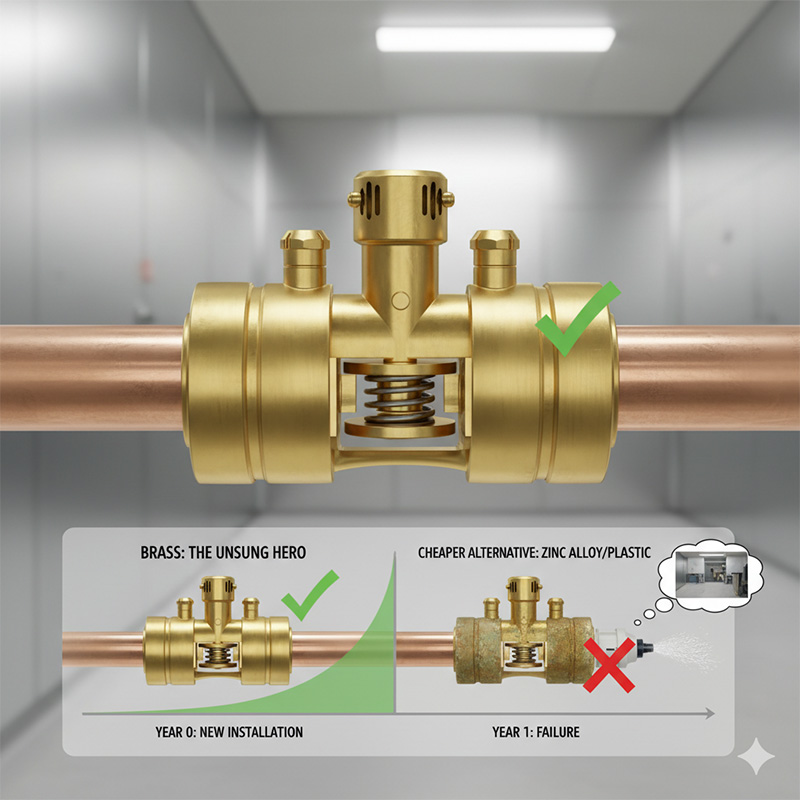

Why is Brass the Unsung Hero of Plumbing Fittings?

You install a new, shiny fitting, but within a year you see green corrosion or a fine spray of water. This small failure can lead to big problems, causing damage and waste.

The problem starts with the wrong material. Quality fittings use solid brass for its unique properties. Cheaper alternatives like zinc alloys or plastics simply can't withstand the constant pressure and corrosive effects of water over time.

For a designer like you, Jacky, it always comes back to material science. The choice to use brass is the first and most critical step in building a reliable product. Water can be surprisingly aggressive, and when it's under pressure 24/7, it will find any weakness in a material. Cheaper zinc alloys are prone to a type of corrosion called dezincification, where the zinc leaches out, leaving a weak, porous copper structure that eventually fails. Plastic becomes brittle with UV exposure and can easily crack if overtightened. Solid brass, on the other hand, provides an incredible defense. Its strength handles the pressure, its composition resists corrosion, and modern alloys are completely lead-free and safe. It's the foundation upon which all other quality steps are built.

Material Performance Showdown

| Material | Corrosion Resistance | Pressure Tolerance | Long-Term Durability |

|---|---|---|---|

| Solid Brass | Excellent | Excellent | Excellent |

| Stainless Steel | Excellent | Excellent | Excellent (often more expensive) |

| Zinc Alloy (ZAMAK) | Poor | Fair | Poor (Prone to internal failure) |

| ABS Plastic | Good | Poor | Poor (Becomes brittle with age/UV) |

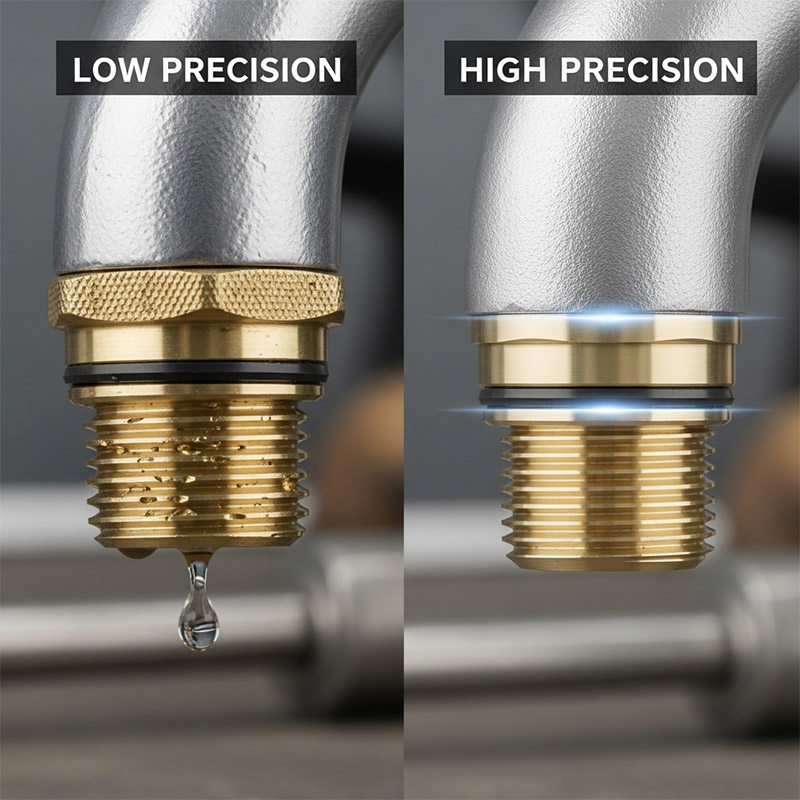

How Can a Machine's Precision Prevent a Tiny Drip?

You've bought a quality fitting, but it's tough to thread onto the faucet, feeling gritty and tight. A poor fit means a potential leak, no matter how hard you crank on it.

This frustration comes from low-precision manufacturing. True leak prevention depends on Computer Numerical Control (CNC) machining, which creates flawless threads and perfectly smooth sealing surfaces with microscopic accuracy.

Once you have a solid bar of high-quality brass, you need to shape it. This is where the magic of CNC machining comes in. Think of it as a robotic sculptor guided by an incredibly detailed computer program. This process allows us to hold "tolerances" – the acceptable range of variation for a dimension – that are incredibly tight, often down to the width of a human hair. This precision is most critical on the threads and the sealing surfaces. The threads on a CNC-machined part are perfectly formed, clean, and smooth. This ensures the fitting screws on easily and distributes pressure evenly. The sealing surface, where a rubber washer sits, must be perfectly flat and smooth. Any tiny scratch or burr left from a sloppy process can create a microscopic channel for water to escape, resulting in a slow, persistent drip. It’s this fanatical attention to detail that separates a part that "looks right" from a part that is right.

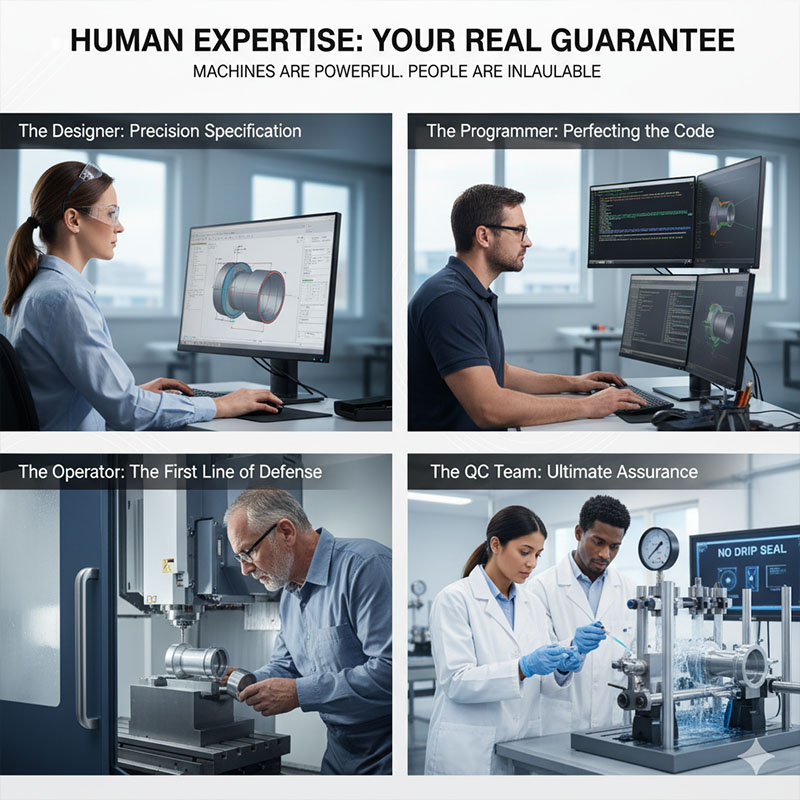

Why Are the People in the Factory Your Best Guarantee Against Failure?

You buy a part that looks perfect, but it fails under a sudden pressure surge. You can't see the microscopic flaws or rushed processes hidden inside the metal from the store shelf.

Your best guarantee isn't just the machine, but the experienced people overseeing the entire process. From the designer to the final inspector, human expertise turns a good process into a great product through rigorous testing and observation.

Automation is powerful, but it's not the whole story. True quality comes from a partnership between skilled people and precise machines. It starts with a product designer, like yourself, who specifies the correct wall thickness and tolerances needed for the application. Then a CNC programmer translates that design into perfect machine code. On the factory floor, a seasoned machine operator is the first line of defense. They can hear when a cutting tool is starting to get dull before the machine's sensors can. They inspect the first part off a new run to ensure everything is perfect. Finally, the quality control team performs the critical final checks. They take random parts from a batch and subject them to extreme pressure tests, often 5 times the normal household water pressure, to ensure they won't burst. They test the seals to confirm a drip-free connection. These people are your real guarantee, providing a level of judgment and experience that a machine alone cannot.

Conclusion

Every leak-free connection is a chain of trust. It is built from a thousand small but deliberate manufacturing details, from the metal to the machine to the people behind it.