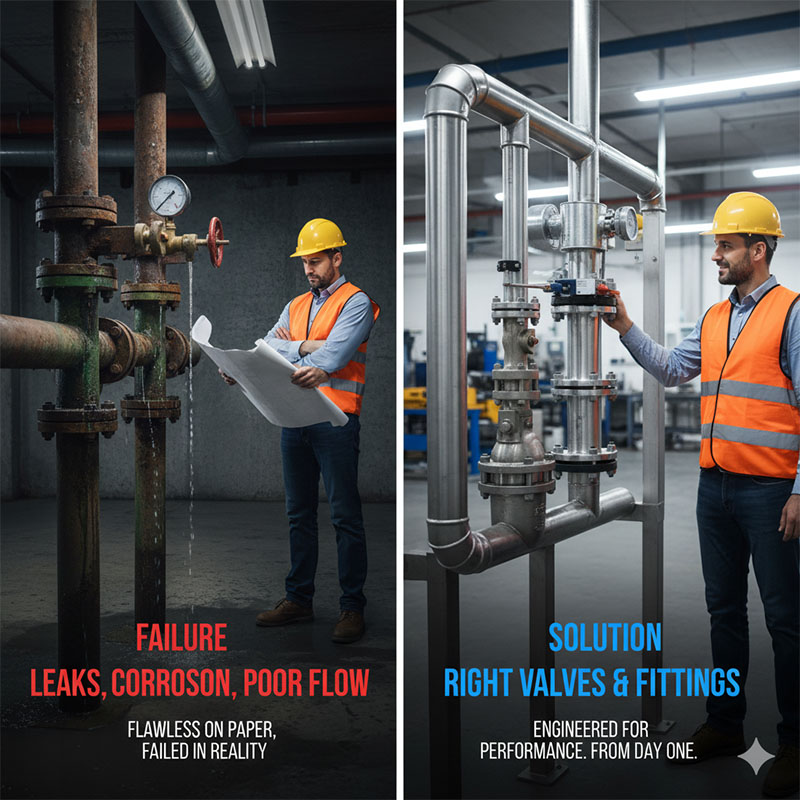

How Do Right Valves and Fittings Solve Common Piping System Problems?

Your design is flawless on paper, but in the real world, it fails. Persistent leaks, unexpected corrosion, and poor flow can ruin a project and your reputation.

The solution starts with the components you choose. High-quality valves and fittings are engineered to prevent these exact problems, ensuring your system performs as designed from day one.

I learned a tough lesson early in my career about the "cost" of a fitting. A client was building a series of water purification skids and decided to save a few dollars per unit by using a cheaper, generic brand of stainless steel fittings. Six months after deployment, we got frantic calls. The fittings were weeping and showing rust streaks. The cheaper fittings weren't a true 316L alloy. The "savings" of a few thousand dollars ended up costing them over a hundred thousand in recalls and repairs. That experience taught me that a fitting isn't just a connector; it's insurance against failure. Your component choices are the foundation of your system's reliability.

How Do You Stop Persistent, Costly Leaks?

You've tightened a connection as much as possible, but it still develops a slow drip. This causes product loss, safety hazards, and customer complaints, forcing costly service calls.

The problem is often not the tightness but the quality of the seal. Precision-machined surfaces and high-grade seals in quality fittings create a reliable, leak-proof connection that lasts.

Leaks almost always start at a connection point. A tiny imperfection is all it takes. A common culprit is poorly cut threads. If the threads are rough or don't have perfect geometry, they create tiny gaps, even when fully tightened. Another major failure point is the sealing surface itself. In fittings that use an O-ring or gasket, the metal surface it presses against must be incredibly smooth. A microscopic scratch or a burr left from the machining process can slice or damage the seal, creating a persistent leak that's hard to find. We solve this by using CNC machines that produce surgically precise threads and mirror-smooth sealing faces. We then use high-quality seal materials like Viton®, which resist chemicals and compression far better than standard rubber. It’s a system designed to create a perfect seal every time.

The Anatomy of a Leak-Proof Connection

-

### Thread Quality Imperfect threads prevent a full, secure engagement. Our precision threads ensure maximum contact and a tight, vibration-resistant fit.

-

### Sealing Surface Finish A rough surface will always compromise a seal. We machine our sealing faces to a specific, smooth finish (measured in Ra) to ensure O-rings and gaskets work perfectly.

| Feature | Standard "Commodity" Fitting | Our Precision Fitting |

|---|---|---|

| Threads | Often poorly formed, loose tolerance. | CNC-machined for perfect engagement. |

| Seal Face | Inconsistent, may have tool marks. | Machined to a verified smooth finish. |

| Material | Questionable material quality. | Verified, high-grade alloys. |

How Can You Prevent Corrosion From Destroying Your System?

You specified a "stainless steel" system, but after a few months in service, it's rusting. This compromises the structural integrity and can contaminate the fluid you are transporting.

The problem is that not all stainless steel is the same. The right corrosion-resistant alloy must be chosen for the specific fluid and environment to guarantee long-term performance.

This is one of the most critical issues in fluid system design. An engineer might specify "stainless steel" thinking it's a magical material that never rusts. But there are many different grades. The most common is 304 stainless steel. It works great for general applications like drinking water. But if your system is handling salt water, chlorides, or certain chemicals, the 304 grade will start to pit and corrode. For those more aggressive environments, you need 316L stainless steel. The "L" stands for low carbon, and it contains an element called molybdenum. This addition dramatically increases its resistance to chloride corrosion. For a designer like Jacky, making this distinction is vital. Choosing the right material grade isn't an upgrade; it is the correct engineering choice to prevent premature failure from the inside out.

Material Selection: Your Best Defense

-

### Understanding the Environment The first step is always to know what fluid is in the pipe and what the external environment is like. This dictates the material choice.

-

### Beyond "Stainless Steel" Always specify the exact grade. The difference between 304 and 316L can be the difference between a system that lasts 20 years and one that fails in one.

| Material | Best For | Avoid With |

|---|---|---|

| Brass | Air, water, inert gases. | Saltwater, strong acids. |

| SS 304 | Water, food products, mild chemicals. | Chlorides, saltwater, bleach. |

| SS 316L | Saltwater, chemicals, pharmaceuticals. | High-concentration strong acids. |

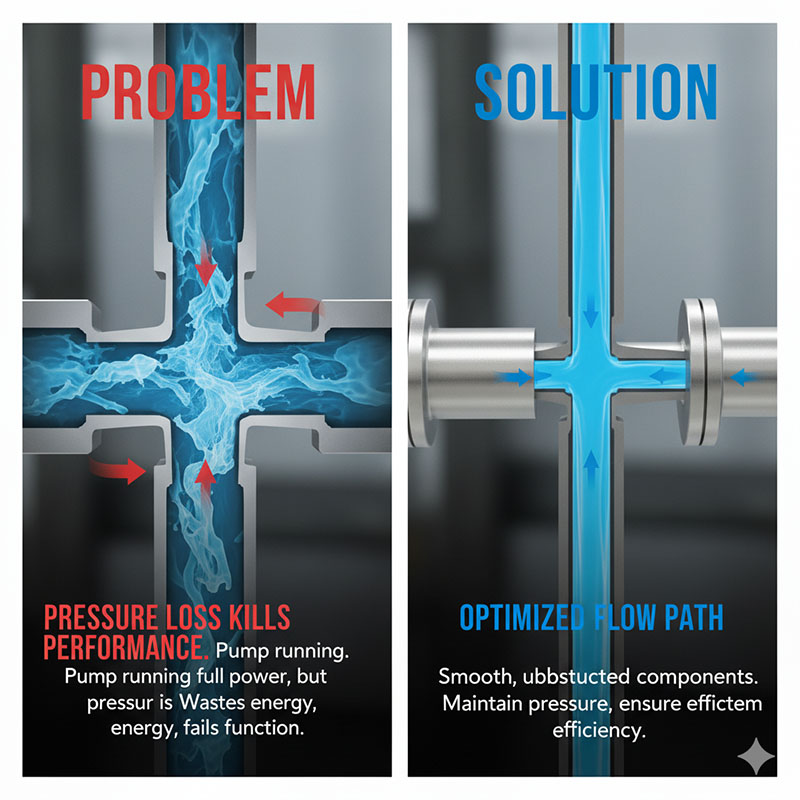

How Do You Eliminate Pressure Loss That Kills Performance?

Your pump is running at full power, but the flow rate or pressure at the other end is too low. The system isn't performing to spec, wasting energy and failing its function.

The energy is being lost to turbulence inside your valves and fittings. Choosing components with a smooth, unobstructed flow path is key to maintaining pressure and system efficiency.

Every time fluid makes a turn or goes through a valve, it loses a little bit of energy and pressure. This is called pressure drop. While you can't eliminate it completely, you can minimize it with smart component selection. A standard ball valve, for example, might have a port, or hole, through the ball that is smaller than the inner diameter of the pipe. This restriction forces the fluid to squeeze through, creating turbulence and a significant pressure drop. A "full-port" or "full-bore" ball valve, on the other hand, has a hole the same size as the pipe. The fluid flows straight through with almost no disturbance. The same concept applies to fittings. A sharp, squared-off 90-degree elbow creates much more turbulence than one with a gentle, sweeping bend. For a designer, adding up these small losses can result in a system that simply doesn't work.

Designing for Flow Efficiency

-

### The Importance of the Flow Path Look at the inside of a fitting. Is it a smooth, open path, or is it full of sharp edges and restrictions? The answer determines your system's efficiency.

-

### Full Port vs. Standard Port For any critical application where flow is important, a full-port valve is usually the better choice. It acts like a seamless piece of the pipe when it's open.

| Component Type | Low-Efficiency Design | High-Efficiency Design |

|---|---|---|

| Ball Valve | Standard or reduced port. | Full-port / Full-bore. |

| Elbow Fitting | Sharp 90-degree angle. | Long-radius or "sweep" elbow. |

| Internal Finish | Rough, as-cast surface. | Smooth, machined bore. |

Conclusion

The right components solve problems before they happen. By choosing fittings that prevent leaks, resist corrosion, and preserve flow, you design reliability and performance directly into your system.