Are You Confused by Refrigerant Adapter Choices and Need a Guide to Cut Through the Noise?

You're ready to recharge an A/C system, but you're staring at a wall of adapters. Choosing the wrong one means delays, wasted money, and the risk of refrigerant leaks.

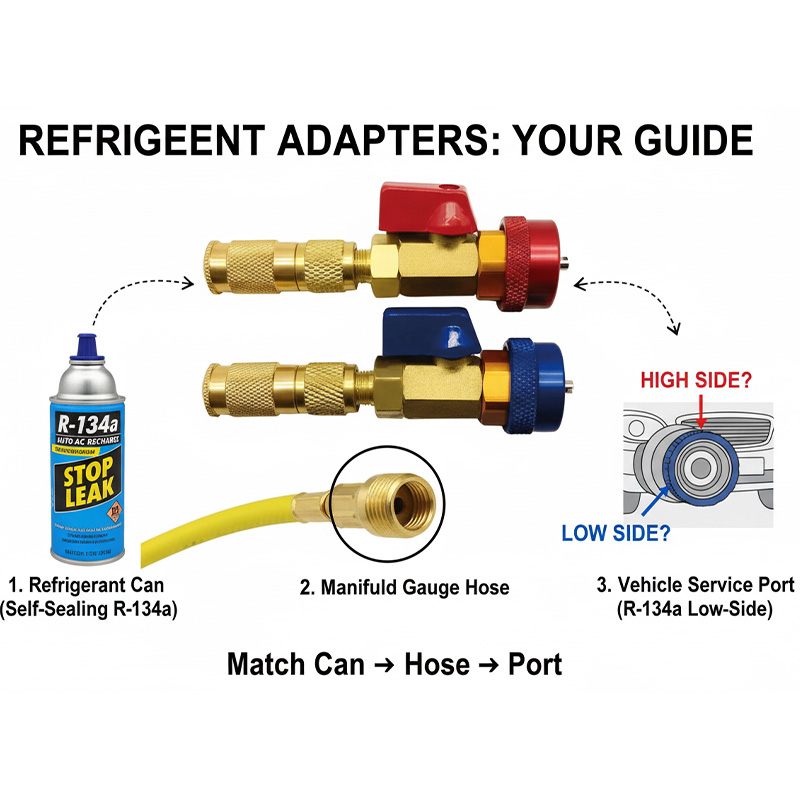

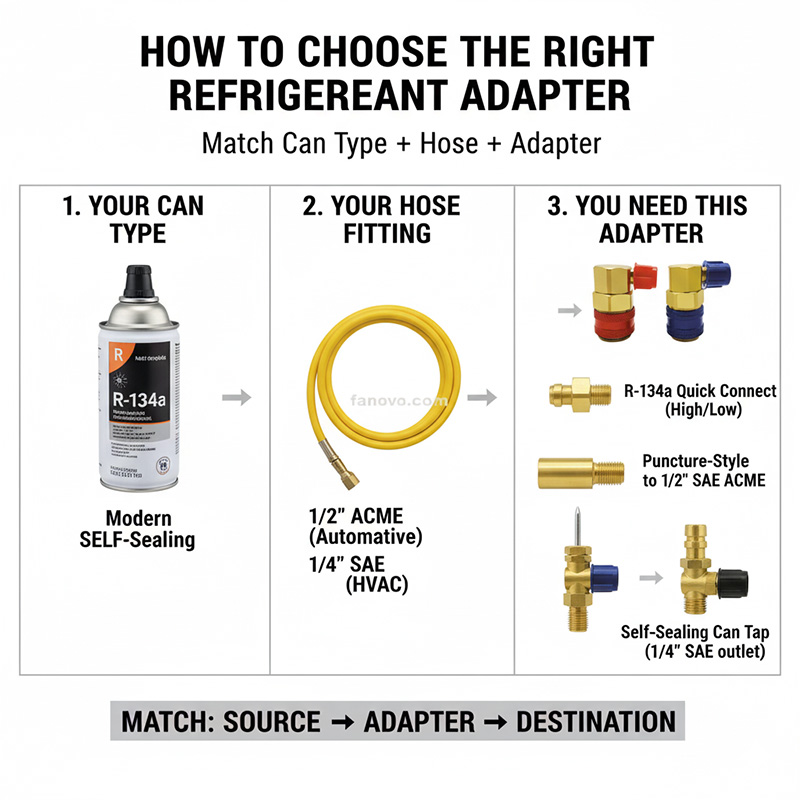

This guide simplifies your choice. The key is to match three things: the refrigerant can type, your gauge set's hose fitting, and the vehicle's service port. An adapter bridges the gap between the can and the hose.

Jacky, this sea of adapters reminds me of the early days of CNC machining. Every manufacturer had their own proprietary tool holders and control systems. It was a nightmare. Compatibility is a huge issue in any technical field. The good news is, just like with machine tools, there is a logic to the apparent chaos of refrigerant fittings. It all comes down to understanding why different standards exist and how to bridge them. Let's break it down so you're never confused again.

Why Are There So Many Different Refrigerant Adapters?

You just want to connect a can to a hose. So why do you need to choose between a dozen different-looking brass and aluminum fittings? It feels unnecessarily complicated.

The variety exists because of evolving safety regulations and different types of refrigerants. Over time, cans changed from puncture-style to self-sealing, and automotive systems moved from R12 to R134a to R1234yf, each requiring unique, non-interchangeable fittings to prevent mistakes.

This isn't just about making things difficult; it's smart design driven by safety and environmental protection. Each new standard aimed to solve a problem with the old one. Think of it like the evolution of USB connectors from Type-A to Micro to Type-C.

The Evolution of Standards

- The Old Days (R12 and Puncture Cans): The original systems used R12 refrigerant and simple puncture-style cans. The standard fitting on gauge sets was typically a 1/4" SAE flare fitting. These are still common in residential HVAC.

- The R134a Era (Automotive): When cars switched to the more ozone-friendly R134a, the industry introduced a new fitting, the 1/2" ACME thread, to prevent accidentally filling an old R12 system with the wrong gas.

- The EPA Mandate (Self-Sealing Cans): To reduce refrigerant venting, the EPA mandated that small cans (under 2 lbs) must be self-sealing. This created a new can top that required a new type of can tap.

- The Latest Standard (R1234yf): The newest automotive refrigerant, R1234yf, has its own unique left-hand threaded port to prevent cross-contamination.

This evolution led to the jungle of adapters we see today. Each one is a specific bridge between these different generations of technology.

How Do You Choose the Right Adapter for Your Specific Job?

You're holding your refrigerant can and your gauge set, but they won't connect. Buying the wrong adapter is a waste of time and could even lead to damaging your tools or system.

Choosing the right one is a simple three-step process. First, identify your can type. Second, identify your hose fitting size. Finally, select the adapter that connects those two specific ends.

-

What Should You Look for in a High-Quality Refrigerant Adapter?

You've found an adapter that fits, but it's made of cheap aluminum and feels flimsy. Using a poor-quality fitting could lead to leaks, stripped threads, or a sudden failure under pressure.

Look for quality materials and construction. Solid brass is far superior to aluminum as it won't strip easily. Also inspect the seals; a good adapter will have thick, durable rubber O-rings or gaskets to ensure a leak-proof connection.

As designers, we know that material choice is critical to a product's function and lifespan. This is especially true for parts used under pressure.

Material: Brass is Best

Solid brass is the preferred material for refrigerant fittings. It's strong, corrosion-resistant, and the threads are far less likely to strip or gall compared to cheaper aluminum. When you hold a solid brass fitting, you can feel the density and quality. It’s a sign that the manufacturer didn't cut corners.

Seals and Gaskets: The Weakest Link

The seal is where most leaks happen. Look for adapters with pre-installed, high-quality rubber O-rings. A good seal should feel pliable, not dry or brittle. Some premium adapters even come with a spare O-ring, which is a great sign of a thoughtful manufacturer.

Knurling and Grip

A well-designed adapter will have deep, functional knurling on the parts you need to tighten by hand. This allows you to get a good, snug grip for a secure, leak-free connection without needing to grab a pair of pliers, which could damage the fitting. It's a small detail that makes a big difference in usability.

Conclusion

Don't let the variety of refrigerant adapters confuse you. By identifying your can and hose, and choosing a high-quality brass fitting, you can ensure a safe, efficient, and leak-free A/C service.