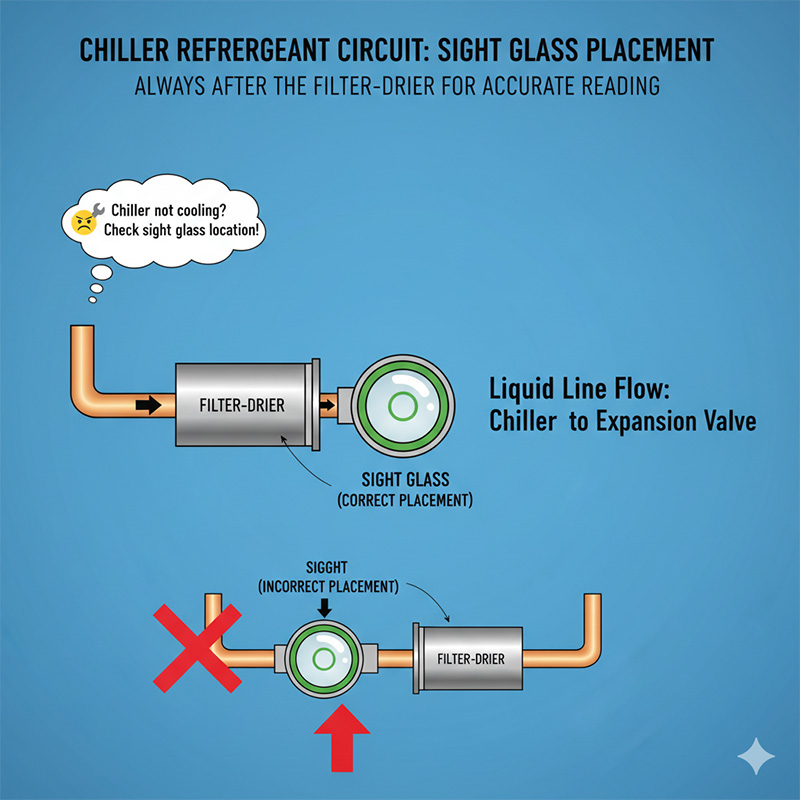

Should Your Chiller's Sight Glass Go Before or After the Filter-Drier?

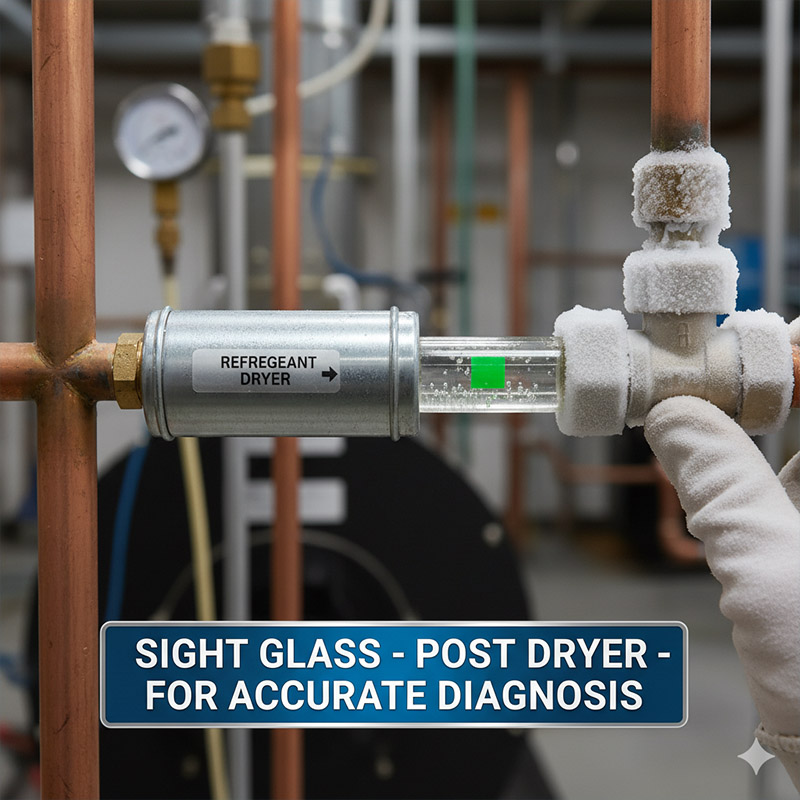

You're desperately trying to fix a chiller that isn't cooling your mold properly. The sight glass looks clear, but you still suspect there's a problem with the refrigerant circuit.

This confusion often happens when the sight glass is in the wrong place. To get an accurate reading, the sight glass must always be installed immediately after the filter-drier in the liquid line.

I learned this the hard way on a critical medical molding project. The brand-new process chiller kept faulting, and the cycle times for the mold were all over the place. The maintenance technician was convinced the system was low on refrigerant because he kept seeing bubbles in the sight glass. He added more refrigerant, but this just caused the compressor's high-pressure alarm to trip. After hours of frustration, I took a closer look at the chiller's plumbing. The manufacturer had installed the sight glass before the filter-drier. The bubbles he was seeing were normal before the drier, but they were masking the real problem. The filter-drier was partially clogged from installation debris, which we only discovered after we moved the sight glass to its correct position after the drier. We replaced the drier, and the system ran perfectly. It proved that a diagnostic tool in the wrong spot is worse than no tool at all.

Why Is Placing the Sight Glass After the Drier So Critical for Diagnosis?

You're staring at the sight glass, and it's telling you the refrigerant is dry. But your system is still showing classic signs of moisture, like a frozen expansion valve.

You feel like you can't trust your tools. The conflicting information makes it impossible to know if you have a moisture problem, a refrigerant charge problem, or something else entirely.

Placing the sight glass after the filter-drier is the only way it can perform its two essential jobs: confirming a proper refrigerant charge and verifying that the drier has successfully removed moisture.

Let's dive deeper into why this position is the only one that makes sense. A modern sight glass isn't just a window; it's a two-part diagnostic tool. First, it shows you if there's a solid, bubble-free column of liquid refrigerant heading to the expansion valve. Bubbles here mean the refrigerant is flashing to gas early, usually due to a low charge or a restriction. Second, the moisture indicator in the center changes color to show the presence of water vapor. If you place the glass before the drier, you are only inspecting the refrigerant before it has been cleaned and dried. This is not useful. You need to see the condition of the refrigerant after the filtering and drying process to confirm that the filter-drier is actually working. A sight glass after the drier is your system's quality control checkpoint.

Sight Glass Readings: Before vs. After the Drier

| Reading | Placed BEFORE Drier | Placed AFTER Drier (Correct) |

|---|---|---|

| Bubbles Present | Could be normal turbulence. Not a reliable indicator of low refrigerant charge. | Indicates a low refrigerant charge or a major restriction upstream. |

| Moisture Indicator "Wet" (Yellow) | Expected. Refrigerant hasn't been dried yet. This is useless information. | Critical Warning! The filter-drier is saturated and must be replaced immediately. |

| Moisture Indicator "Dry" (Green) | Tells you nothing about the drier's performance. | Confirms the filter-drier is working correctly and the system is free of moisture. |

Is There Ever a Reason to Put a Sight Glass Before the Drier?

You're trying to pinpoint a blockage causing high pressure in your chiller. You suspect the filter-drier is clogged, but you don't want to replace it without being sure.

Guesswork is expensive. Replacing a large filter-drier can cost hundreds of dollars in parts and labor, and you risk introducing more contaminants into the system if the drier wasn't the problem.

In advanced diagnostics, installing a second sight glass—one before and one after the drier—can definitively prove that the filter-drier is clogged, saving you time and money.

This two-glass setup is not standard, but it's an incredibly powerful trick for troubleshooting. A clogged filter-drier acts like a dam, creating a restriction in the liquid line. This restriction causes a significant pressure drop across the drier. As the high-pressure liquid refrigerant is forced through this tight spot, the pressure drop causes it to "flash"—boil prematurely into a gas. With two sight glasses, you can see this happening in real time. The glass before the drier will show a solid column of liquid, while the glass after the drier will be full of bubbles. This visual confirmation is instant proof that the pressure drop is happening inside the filter-drier, meaning it's clogged and must be replaced. This method allows you to be 100% certain of your diagnosis before you open up the system. It's a professional technique for critical equipment where diagnostic speed is everything.

Two-Sight-Glass Diagnostic Chart

| Sight Glass #1 (Before Drier) | Sight Glass #2 (After Drier) | Diagnosis |

|---|---|---|

| Solid Liquid | Bubbles | Clogged filter-drier. The pressure drop across the drier is causing the refrigerant to flash. |

| Bubbles | Bubbles | Low refrigerant charge. The system needs more refrigerant; the drier is likely not the problem. |

| Solid Liquid | Solid Liquid | System is healthy. No significant restriction or charge issue is visible here. |

Conclusion

For 99% of applications, the rule is simple: always place your sight glass immediately after the filter-drier. This correct placement turns it into a reliable tool that protects your chiller and your production schedule.