Are You Tired of Frequent Sight Glass Failures? Here's an Engineer's Guide to Prevention.

A cracked sight glass creates a huge mess and a safety hazard. This unexpected failure means costly downtime and emergency cleanups, all from one small component.

Preventing sight glass failure comes down to three things: selecting the right materials, respecting pressure/temperature limits, and following correct installation procedures. This turns a liability into a reliable window into your process.

Jacky, I know as a designer, you think about the big picture. But sometimes it's the little details that bring a whole system down. I remember we had a large hydraulic power pack for a stamping press. The sight glass on the oil tank suddenly failed overnight. No one was there, but we came into a shop floor covered in 50 gallons of hydraulic oil. It was a nightmare to clean up, and the press was down for a full day. We found out the maintenance team had replaced the sight glass a month earlier and used a standard rubber gasket. The hydraulic oil slowly degraded the rubber until it gave way. That day I learned a valuable lesson: the gasket is just as important as the glass itself.

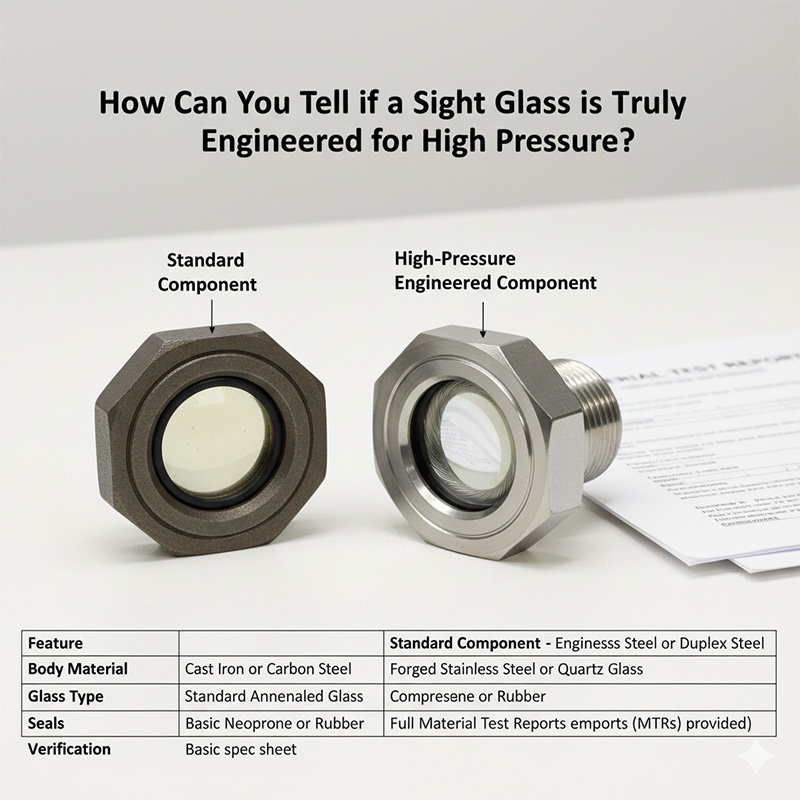

Is Your Sight Glass Material a Mismatch for Your Application?

You specify a sight glass, but it quickly becomes cloudy, etched, or cracked. This leaves operators blind to fluid levels and creates a weak point just waiting to fail.

The problem is often a material mismatch. You must choose a glass type and a gasket material that are chemically compatible with the fluid and can handle the operating temperature.

For a designer, material science is key. A standard, cheap sight glass is usually made from soda-lime glass, the same stuff as windowpanes. It's fine for water, but it has poor chemical resistance and can't handle rapid temperature changes. For most industrial jobs, you need to specify Borosilicate glass. It's what they use for laboratory beakers for a reason: it's tough and handles both chemicals and thermal shock. The seal is just as critical. The wrong seal can swell up, become brittle, or dissolve completely. This is a common failure point that is often missed during the design phase. Matching the glass and the seal to the application isn't an upgrade; it's a basic requirement for a reliable system.

Material Selection Guide

| Fluid / Condition | Recommended Glass Type | Recommended Seal Material |

|---|---|---|

| Water, Glycol, Air | Borosilicate | EPDM |

| Hydraulic Oils, Fuels | Borosilicate | NBR (Buna-N) or Viton (FKM) |

| Aggressive Chemicals | Borosilicate or Fused Quartz | Viton (FKM) or PTFE (Teflon) |

| High Temperature Steam | Borosilicate (Laminated) | Graphite |

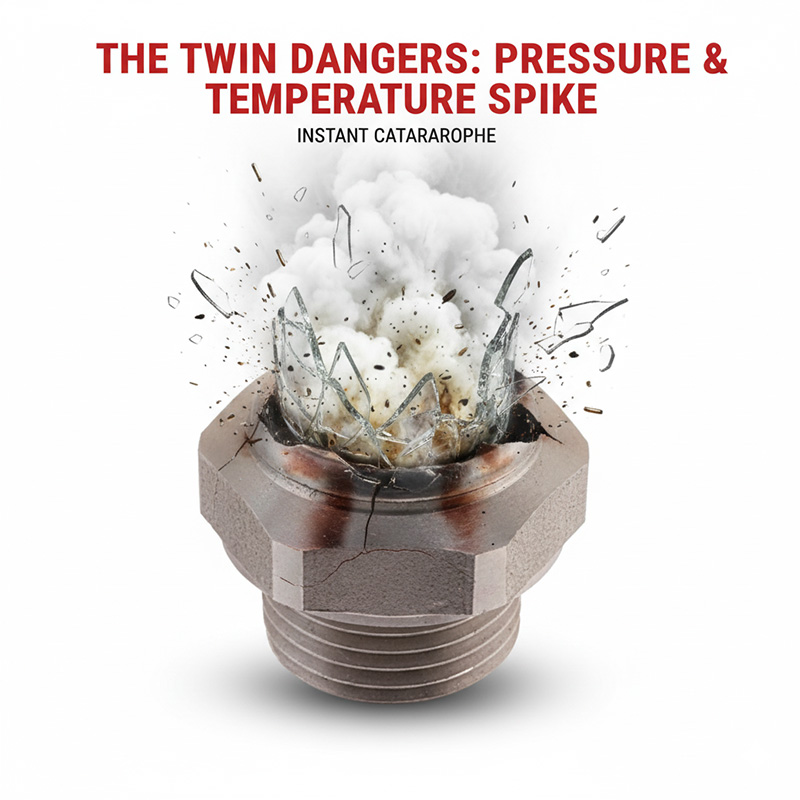

Are You Overlooking the Twin Dangers of Pressure and Temperature?

You choose a sight glass that fits perfectly. It looks strong and secure. But a pressure spike from a valve closing or a surge of hot fluid shatters it instantly.

Pressure and temperature are the enemies of any sight glass. You must ensure the component's stated pressure and temperature ratings are well above the maximum limits of your system.

This is one area where you can't cut corners. The pressure rating you see on a data sheet is often for ambient temperature. As the temperature of your system goes up, the maximum pressure the sight glass can safely handle goes down. This is called derating. For example, a sight glass rated for 150 PSI at 70°F might only be safe for 75 PSI at 300°F. You must look at the manufacturer's derating curve to be sure. Another killer is thermal shock. This happens when a fluid that is much hotter or colder than the glass suddenly hits its surface. The rapid expansion or contraction creates stress that can cause an instant fracture. Specifying a component with a wide operating temperature range and using borosilicate glass is your best defense against this.

Key Safety Considerations

| Factor | Why It's Critical for Designers |

|---|---|

| Safety Margin | Always select a sight glass with ratings at least 50% higher than the maximum system pressure. |

| Pressure Derating | Check the manufacturer's chart to find the true pressure rating at your operating temperature. |

| Thermal Shock Rating | Ensure the glass can withstand the maximum temperature difference it will experience in operation. |

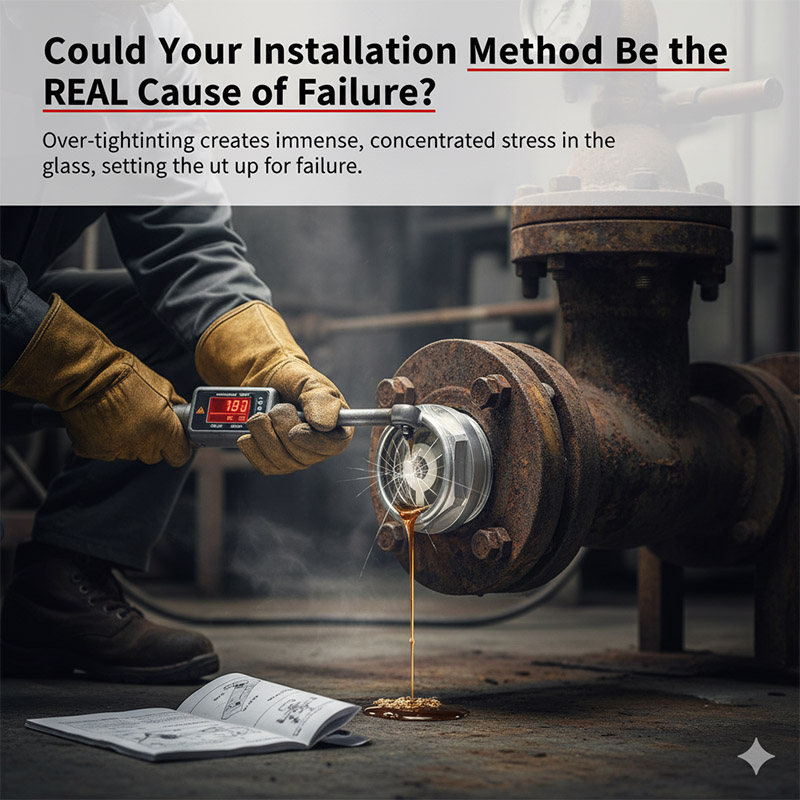

Could Your Installation Method Be the Real Cause of Failure?

You designed with the perfect, top-of-the-line sight glass. You specified all the right materials and ratings. But it still fails prematurely, and you don't know why.

The most common reason for failure in a well-specified sight glass is improper installation. Specifically, over-tightening the mounting bolts creates immense, concentrated stress in the glass, setting it up for failure.

This is a classic problem that happens on the shop floor, but it starts with your design notes. Glass is incredibly strong under uniform compression, but it's very weak against concentrated stress points. When a technician tightens the bolts on a flanged sight glass unevenly or uses an impact wrench, they are creating invisible stress points. The sight glass might look fine, but it's a time bomb. The slightest vibration or pressure fluctuation can cause a crack to start from one of those stress points. As a designer, you can help prevent this by adding a simple note on your drawing: "Install bolts to XX ft-lbs torque using a star pattern. Do not over-tighten." It's a simple instruction that can save a very expensive component.

Installation Best Practices Checklist

| Step | Action | Reason |

|---|---|---|

| 1. Clean Surfaces | Wipe the flanges, gasket, and glass. Ensure they are free of debris. | Debris can create a leak path or a high-stress point on the glass. |

| 2. Correct Gasket | Verify the gasket is the correct material and size. | Prevents chemical degradation and ensures a proper seal. |

| 3. Hand-Tighten | Install all bolts and hand-tighten until they are snug. | Ensures the sight glass is centered and seated evenly. |

| 4. Use Torque Wrench | Tighten bolts in a star or cross pattern, in three stages (e.g., 30%, 60%, 100% of final torque). | Applies pressure evenly across the glass surface. |

| 5. Final Check | Wait 15 minutes and do a final torque check on all bolts. | Gasket material can "settle," requiring a final tightening. |

Conclusion

A reliable sight glass isn't an accident. It's the result of diligent design: proper material selection, respecting pressure and temperature limits, and insisting on correct installation. Get these three right.