What Does Quality Valve Manufacturing Really Take?

You specify a quality valve, but it fails unexpectedly. Hidden manufacturing defects can undermine even the best designs, causing frustrating and costly downtime that reflects on you.

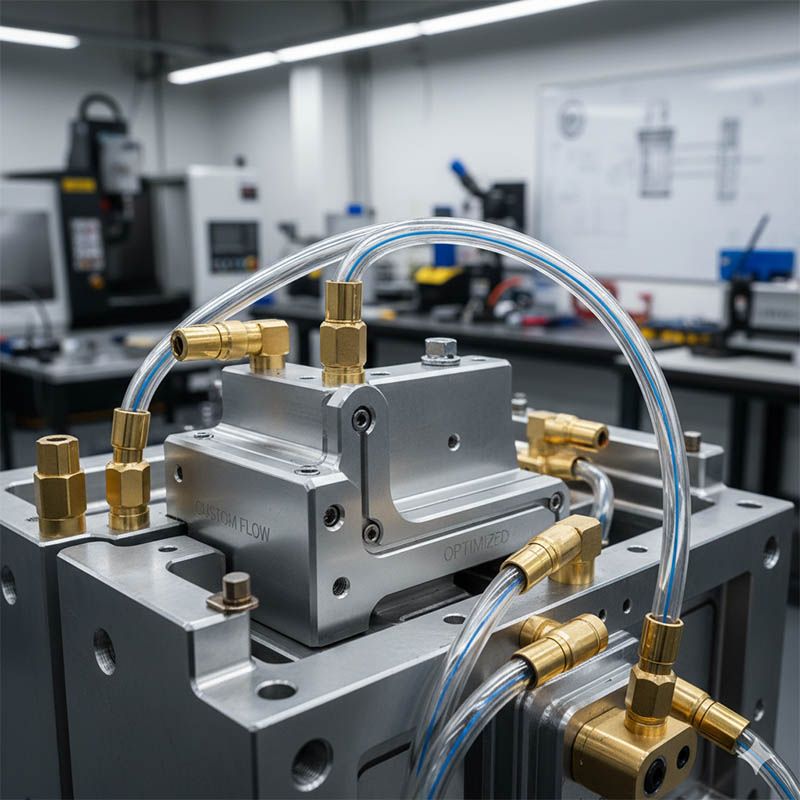

Quality manufacturing is a chain of control over every step. It starts with certified raw materials and continues through precision machining, meticulous assembly, rigorous testing, and proper finishing. One weak link breaks the chain.

A few years ago, a new client in the chemical processing industry came to me. They were having a nightmare with a competitor's ball valves. They looked fine, and the material certificates seemed to be in order, but they were leaking from the stems within months. They bought a large batch, and the problem was everywhere. We took one of the failed valves and cut it in half on a bandsaw. The problem was immediately clear. The internal bore where the stem seals sat was horribly machined. You could see the "chatter" marks from the cutting tool. That rough surface was acting like a file, shredding the soft seals every time the valve was operated. The competitor saved a few dollars by machining faster and not checking the surface finish. That decision cost my new client tens of thousands in downtime and labor. It's a lesson you never forget: the quality you can't see is the quality that matters most.

Why Does the Process Start Before the First Machine is Turned On?

Your design relies on a strong casting or forging. But hidden porosity and internal defects can lead to catastrophic failure, making you question the material's integrity.

It begins with certified raw materials. A quality manufacturer verifies the exact chemical composition of the metal. Furthermore, forging is chosen over casting for critical parts to guarantee a void-free, stronger material structure.

The foundation of any strong part is the metal itself. You can have the best machines in the world, but if you start with poor material, you'll make a poor part. The first step is always material certification. We ensure every batch of steel or alloy comes with a mill test report that verifies its chemical makeup. This guarantees it has the properties you designed for. Then comes the choice between casting and forging. For a critical, high-pressure component, casting can be a risk. It involves pouring liquid metal, which can trap gas and create tiny internal voids. A forging takes a solid billet of certified metal and shapes it with immense pressure. This process refines the grain structure and eliminates any hidden defects. As a designer, Jacky, knowing your part is forged gives you confidence that it has the maximum possible strength, without hidden weak spots.

Forging vs. Casting: The Hidden Difference

| Feature | Casting | Forging |

|---|---|---|

| Internal Structure | Can have hidden porosity/voids | Dense, uniform, void-free |

| Grain Flow | Random, non-directional | Aligned with the part's shape |

| Strength & Toughness | Good | Superior |

| Best Use Case | Complex shapes, low-stress parts | High-pressure, critical components |

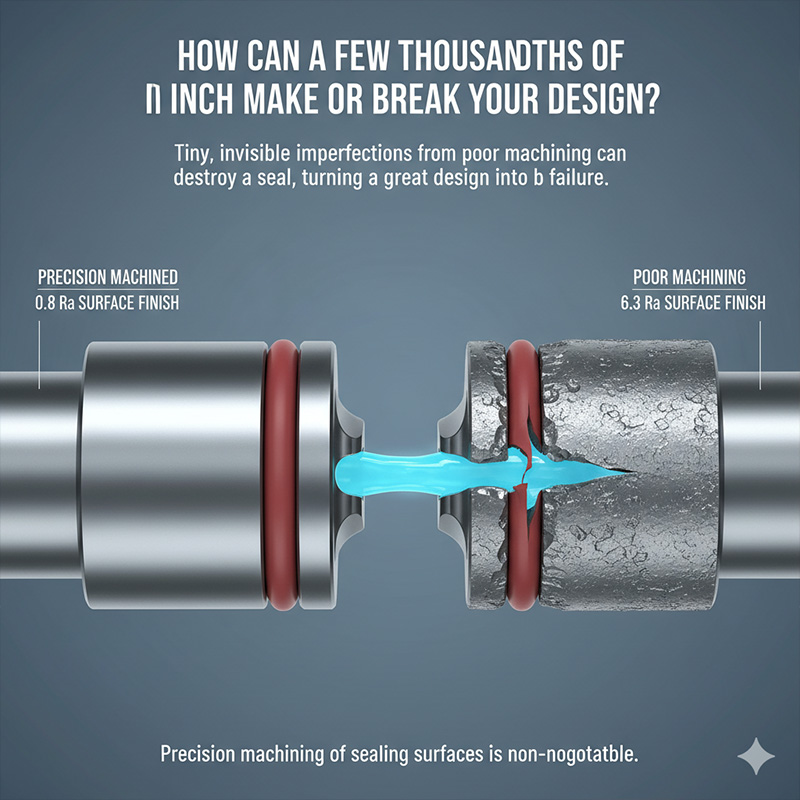

How Can a Few Thousandths of an Inch Make or Break Your Design?

Your new valve is leaking, and you can't figure out why. Tiny, invisible imperfections from poor machining can destroy a seal, turning a great design into a failure.

Precision machining of sealing surfaces is non-negotiable. The smoothness, or "surface finish," must be controlled to a microscopic level. A rough finish will tear apart soft seals, causing leaks.

This is where the magic of precision happens. After a part is forged, it’s put into a CNC (Computer Numerical Control) machine. For a valve, the most critical areas are the surfaces where seals sit and the "ball" or "disc" that stops the flow. These areas must be incredibly smooth. We measure this smoothness in "Ra," or Roughness Average. A lower Ra value means a smoother surface. An everyday machined part might have a finish of 125 Ra. A high-quality sealing surface needs to be 32 Ra or smoother. This level of finish ensures that a soft seal, like one made from PTFE, can press against it and create a perfect, leak-proof barrier without being scratched or torn over time. This isn't just about looking shiny. It is a functional requirement that is absolutely essential for the long-term reliability of the valve.

The Importance of Surface Finish (Ra)

-

### Concentricity and Roundness Beyond smoothness, the geometry must be perfect. The sealing area must be perfectly round, and it must be perfectly centered (concentric) with the rest of the valve. If it's even slightly oval-shaped or off-center, the seal will be unevenly compressed, creating a definite leak path.

-

### The "No-Compromise" Zone Quality manufacturing means treating these machined surfaces as the heart of the valve. It means using the best CNC machines, the sharpest cutting tools, and measuring every critical dimension on every part.

Why is How a Valve is Assembled and Tested Just as Important as Its Parts?

The valve arrives ready to install. But you have no idea if it was assembled correctly. Contamination or improper torque during assembly can lead to immediate failure upon installation.

Quality assembly happens in a clean area, using specific lubricants and calibrated tools. Crucially, every single valve must pass rigorous hydrostatic and pneumatic pressure tests to certify it is 100% leak-free before it ships.

You can have perfectly forged and machined parts, but if you assemble them poorly, the valve will fail. The assembly stage is its own craft. First, it must be done in a clean environment. A single grain of sand or a metal chip can damage a seal during assembly. Second, the right lubricants must be used. Using the wrong grease can cause seals to swell or degrade. Third, everything must be torqued correctly. Overtightening a packing nut can crush the seals, while undertightening it will cause a leak. But the final, most important step, is testing. A quality manufacturer doesn't just "batch test" a few valves from a run. We test every single valve. We conduct a shell test to ensure the body is sound, and a seat test to ensure it seals perfectly when closed. This is your ultimate guarantee of performance.

The Gauntlet of Testing

| Test Type | Purpose | How It's Done |

|---|---|---|

| Hydrostatic Shell Test | To confirm the body's integrity. | Valve is filled with water at 1.5x its pressure rating. |

| Pneumatic Seat Test | To check for tiny leaks at the seat. | Low-pressure air is applied; the valve is submerged to look for bubbles. |

Conclusion

Quality valve manufacturing is a total commitment. It’s about proven excellence at every stage, from certified material to final testing, ensuring reliability is built in, not just inspected.