How Does an Industrial Float Valve Keep Your Chiller Tank from Running Dry?

The emergency alarm sounds. Production halts. The problem isn't the mold or the machine, but an empty chiller tank that has starved your entire facility of cooling water.

This shutdown is often caused by a failed float valve, the simple mechanical device that automatically refills your cooling tower or reservoir. A float valve works using a buoyant ball that rises with the water level, pushing a lever that mechanically closes a water inlet valve.

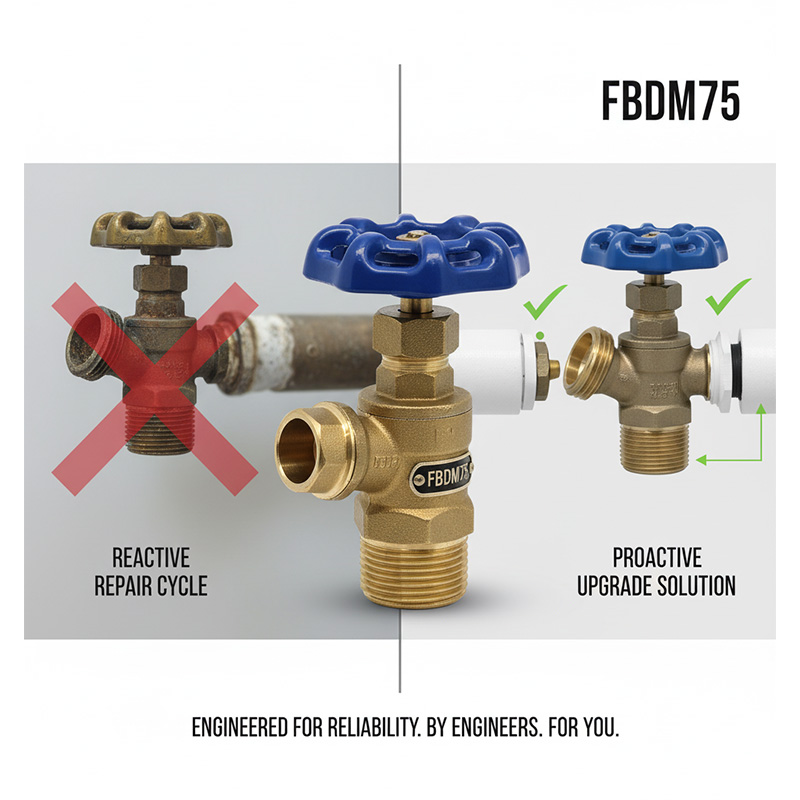

I'll never forget a call from a client who was losing hours of production every other week. Their main chiller tank would mysteriously run low, tripping the low-level sensor and shutting down their pumps. They had replaced the float valve twice with a standard model from a local hardware store. I went to their plant, looked at the tank, and saw the problem immediately. The turbulence from the massive return pipe was creating so much vibration that the plastic arm of the cheap float valve was literally snapping off after a week or two of use. They were using a toilet-filler mechanism to do an industrial job. We installed a heavy-duty, industrial brass float valve with a vibration-damping linkage, and they never had the problem again. It’s a classic case of needing the right tool for the job, even for the simple parts of the system.

How Does the Lever Actually Turn the Water Flow On and Off?

You see the float ball bobbing in the water, but how does that little plastic ball have enough strength to stop the massive pressure of the main water supply line?

The secret is leverage. The long lever arm multiplies the small, gentle upward force from the buoyant float into a powerful sealing force at the valve’s pivot point.

This mechanical advantage allows the float to exert hundreds of pounds of sealing pressure, easily closing the plunger against the water inlet and stopping the flow without any need for electricity or complicated sensors.

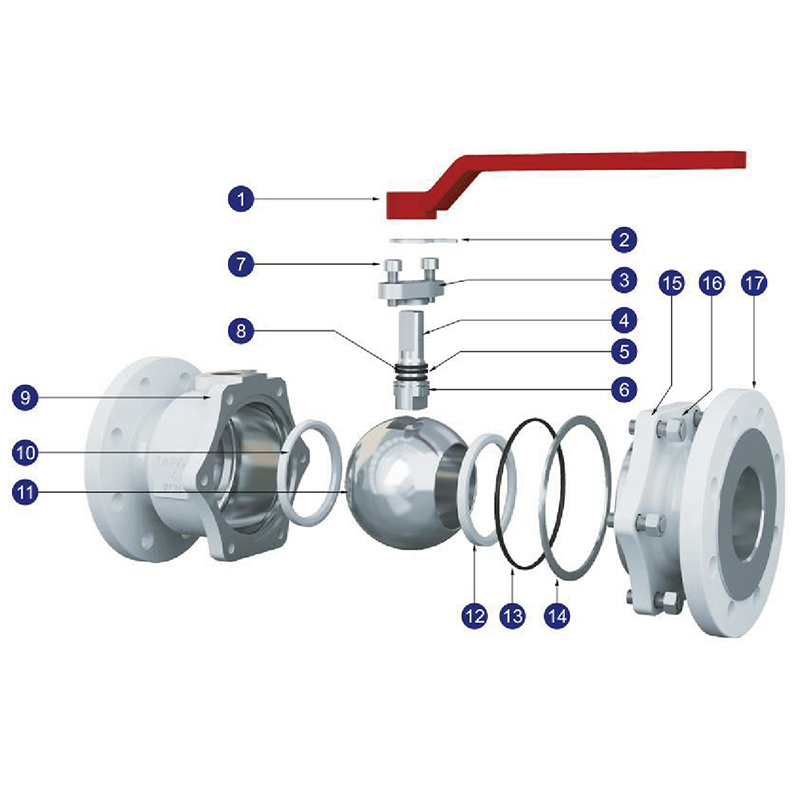

Let's break down how this powerful yet simple system works. It’s a beautiful example of basic physics. The system consists of a few key parts: the float itself, a long lever arm, a pivot point, and a plunger with a rubber seal. When the water level is low, the float hangs down, pulling the arm away from the plunger. This allows water pressure to push the plunger open, filling the tank. As the water level rises, it lifts the buoyant float. This upward force is multiplied by the length of the lever arm. Think of how a long wrench makes it easier to loosen a tight bolt. The long arm gives the float the power to push the plunger firmly against the valve seat, and the soft rubber seal creates a watertight closure, stopping the flow.

The Components of a Float Valve

| Component | Function | Material |

|---|---|---|

| Float Ball | Senses the water level. Provides the initial upward force. | Hollow plastic, copper, or stainless steel. |

| Lever Arm | Multiplies the force from the float. | Brass, stainless steel, or plastic. |

| Pivot | The fulcrum point for the lever arm. | Integrally cast in the valve body, often brass. |

| Plunger / Seal | The moving part that physically stops the water flow. | Brass or stainless steel plunger with a durable rubber seal. |

Why Would a Perfectly Good Float Valve Fail to Shut Off?

Your chiller tank is overflowing, wasting thousands of gallons of treated water and creating a slippery mess. You look at the float valve, and it appears to be working correctly.

This is a classic and frustrating failure mode. The valve often fails not because of a major break, but because a tiny piece of debris is preventing a complete seal.

The most common reason for a float valve to leak or overflow is a worn-out rubber seal or a small piece of rust or scale getting wedged between the seal and the valve seat. This creates a tiny gap that allows water to continuously leak through, even when the float is fully raised.

Troubleshooting these failures is usually straightforward. The first culprit to check is debris. Over time, rust and mineral scale from your water pipes can flake off and get caught in the small orifice of the valve. Even a speck of sand can be enough to prevent a full seal. The second most common issue is the seal itself. The rubber plunger seal is a wear item. After thousands of cycles, it can become hard, cracked, or deformed, losing its ability to create a perfect seal. A less common but possible failure is the float itself. If you're using a hollow float, it can develop a pinhole leak, fill with water, and sink, causing the valve to stay permanently open. This is why for turbulent tanks, a solid foam-filled or heavy-duty spun copper float is often a better choice. Regular inspection of these simple components is the key to preventing a messy overflow.

Troubleshooting Common Float Valve Issues

| Symptom | Common Cause(s) | How to Fix |

|---|---|---|

| Valve won't shut off (overflow) | 1. Debris in valve seat. <br> 2. Worn or damaged rubber seal. <br> 3. Waterlogged float. | 1. Shut off water, disassemble and clean. <br> 2. Replace the rubber seal. <br> 3. Replace the float ball. |

| Valve won't turn on (low water) | 1. Lever arm is stuck or bent. <br> 2. Float is hung up on tank wall or pipes. | 1. Straighten or free up the lever arm. <br> 2. Reposition the valve or float to ensure free movement. |

| Valve chatters or vibrates loudly | Water pressure is too high for the valve's design. | Install a pressure reducing valve (PRV) on the supply line before the float valve. |

Conclusion

The float valve is a simple hero in your cooling system. Understanding its reliance on leverage and keeping it clean from debris are the keys to ensuring it works reliably, preventing costly production shutdowns.