How Does a Frost-Free Spigot Actually Work? An Insider's Breakdown?

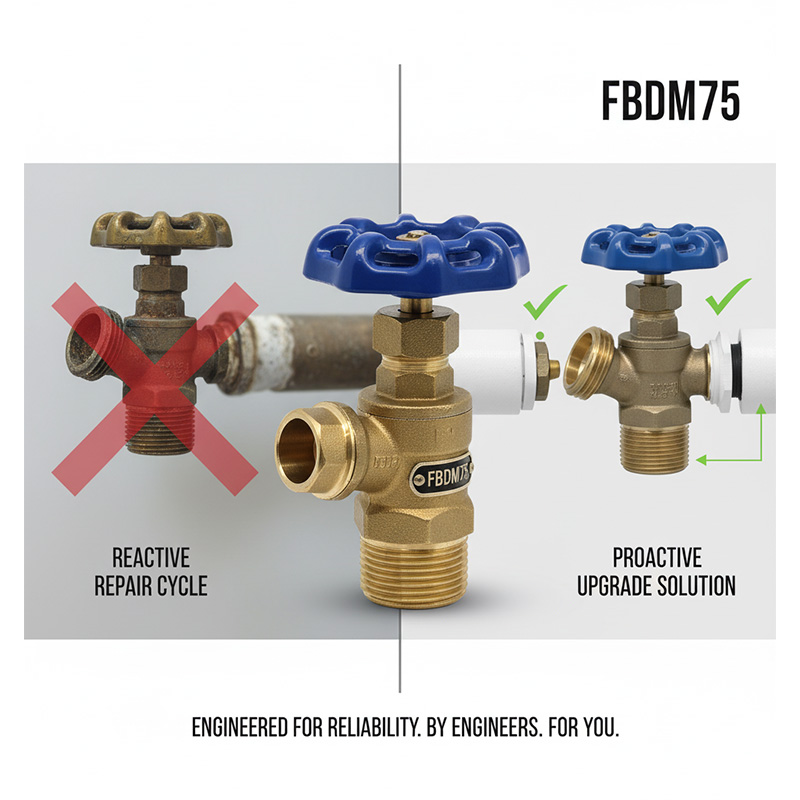

A burst pipe in winter is a costly nightmare. You see a standard spigot and worry about the freeze, the flood, and the fallout. It’s a preventable disaster waiting to happen.

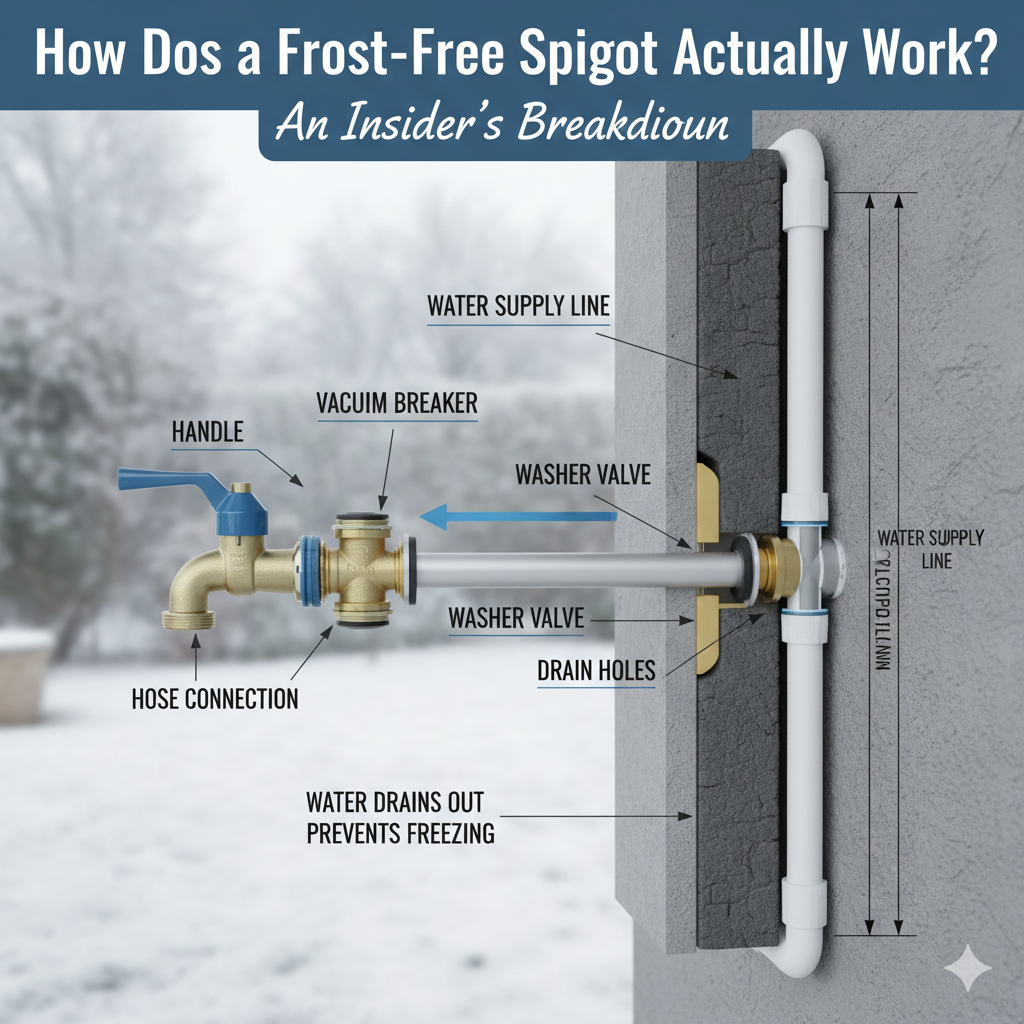

A frost-free spigot, or sillcock, prevents freezing by shutting off the water deep inside the warm wall of your building. Its long stem ensures no water is left in the unheated parts of the faucet, a simple design that eliminates the risk of ice expansion and burst pipes.

This simple mechanical solution is one of the most effective upgrades for any property in a cold climate. But not all frost-free spigots are created equal. As someone who has spent years on the factory floor and built a business around these components, I know the small details that make a huge difference. Let's break down how this device works and what you, as a professional, truly need to look for.

What Exactly Is a Frost-Free Sillcock?

Worried about explaining complex parts to your team or clients? The technical jargon can be confusing, making it hard to show the real value behind this essential piece of hardware.

Think of a frost-free sillcock as a remote control for your water. The handle is outside, but the valve that actually stops the water is on a long stem, positioned deep inside the heated part of the building. This simple extension is the key to its function.

I always tell my new employees to use that "remote control" analogy. The handle you touch is just the button. The real work happens 6, 8, or even 12 inches inside the wall, where it's warm. The principle sounds simple, but engineering that long rod, called a stem, and the valve at its end to perfection is where the real manufacturing skill comes in. It requires precise machining and high-quality materials to ensure it works flawlessly for decades. The entire design is based on one idea: moving the point of water shut-off away from the cold.

Key Components Breakdown

To understand its quality, you need to know its parts. Here’s a simple look at what makes up a frost-free sillcock:

| Component | Function |

|---|---|

| Handle | The user interface. It turns the stem to open or close the valve. |

| Stem | The long rod connecting the handle to the shut-off valve. |

| Valve Seat Washer | A rubber or synthetic seal at the end of the stem that stops the water flow. |

| Faucet Body | The outer casing, angled downwards to allow water to drain out after shut-off. |

| Vacuum Breaker | A safety device that prevents contaminated water from siphoning back into the supply. |

How Does the Frost-Proof Design Prevent Frozen Pipes?

You know frost-free spigots are supposed to work. But what’s the real weak link? What is the one component that separates a reliable sillcock from one that fails and causes damage?

The frost-proof design works by ensuring the valve seat washer, which stops the water, is located inside the heated building. When you turn it off, all water in the exposed pipe drains out, leaving nothing behind to freeze, expand, and cause a burst.

From a factory perspective, the most critical part is the rubber washer at the end of that long stem. I've seen countless cheap faucets fail because the manufacturer used low-grade rubber that gets brittle in the cold. It might work for a year, but then it fails to seal properly. Water slowly seeps past it and into the cold barrel. Then it freezes, expands, and 'bang'—you get a call about a burst pipe inside a client's wall. We insist on high-grade EPDM rubber because we know it's the difference between a product that lasts two years and one that lasts twenty. The material of that tiny washer is a major point of failure, and it’s something many people overlook until it’s too late.

Material Makes the Difference

The type of rubber used for the valve seat washer is not a small detail; it's everything.

| Material | Cold Weather Performance | Durability | Common Use |

|---|---|---|---|

| EPDM | Excellent. Remains flexible down to -60°F (-51°C). | High resistance to aging and weather. | High-Quality Sillcocks |

| NBR (Buna-N) | Poor. Becomes brittle around -40°F (-40°C). | Good for oil, but less durable in weather. | Cheaper, low-quality faucets. |

What Are the Critical Advantages for a Professional Installation?

You're a professional. You need to balance cost, quality, and your reputation on every job. Is spending a few extra dollars on a premium sillcock really worth it for your business?

For professionals, a high-quality frost-free sillcock is not a cost; it's insurance. It drastically reduces the risk of expensive callbacks, protects your reputation, and ensures client satisfaction, all of which are far more valuable than the initial savings on a cheaper part.

Let me be direct. Saving $8 on a sillcock might seem smart, but it's one of the most expensive mistakes a professional can make. I knew a contractor who installed twenty cheap spigots in a new housing development. The first winter, three of them burst. The cost to repair the drywall and water damage completely erased the profit from that entire job. A callback isn't just the price of a new faucet; it's your labor, your fuel, and most importantly, your reputation. A high-quality sillcock is an investment in your business's reliability and profitability. It's the kind of decision that separates the amateurs from the pros who are in it for the long haul.

The True Cost of a Callback

The upfront price tag is only part of the story. Here's a more realistic look at the numbers.

| Cost Factor | High-Quality Sillcock | Low-Quality Sillcock |

|---|---|---|

| Initial Part Cost | $25 | $17 |

| Installation Labor | ~$100 | ~$100 |

| Risk of Failure | Extremely Low | Moderate to High |

| Cost of a Callback | $0 | $500 - $2,000+ |

| Reputation Damage | Protected | High Risk |

| Total Effective Cost | ~$125 | Potentially Thousands |

What Key Features Define a High-Quality Frost-Free Sillcock?

You're at the supply house, looking at a wall of similar-looking spigots. The spec sheets all make big promises. How do you cut through the noise and identify true quality?

Beyond certifications like ASSE 1019, true quality is tangible. A high-quality sillcock feels heavy and solid. Its quarter-turn handle operates smoothly with a firm stop, a sign of precision machining. These are details the spec sheet won’t tell you.

Here's something I’ve learned from handling thousands of parts: you can feel the quality before you ever install it. It's in the 'hand feel'. When you pick up a good one, it has weight; it feels like solid brass, not cheap pot metal. Operate the handle. A well-made quarter-turn valve is smooth and closes with a defined 'thud', not a gritty or loose feeling. This is the difference between precision-machined internal parts and low-tolerance cast components. Before you even look at the box, your hands can tell you which product was built to last and which one was built to a price point. Trust that feeling; it's usually right.

A Professional's Quality Checklist

Use this quick guide to assess quality on the spot.

| Feature | Look For (High Quality) | Avoid (Low Quality) |

|---|---|---|

| Body Material | Heavy, solid forged brass. | Lightweight, appears porous or uneven. |

| Certifications | ASSE 1019, cUPC clearly marked. | Missing or dubious certifications. |

| Handle Action | Smooth, firm operation with a solid stop. | Gritty, loose, or wobbly feel. |

| Seals/Washers | Made from EPDM (often specified). | Unspecified black rubber (likely NBR). |

| Machining | Clean threads, no burrs or sharp edges. | Rough threads, visible casting marks. |

How Can You Partner with the Right Sillcock Manufacturer?

You need a reliable supply of quality parts. But choosing a supplier feels like a gamble. How do you find a manufacturer that's a true partner, not just another vendor?

Find a partner, not a vendor, by asking deeper questions. Move beyond the price list and inquire about their quality control process, raw material traceability, and how they handle problems. A true partner offers transparency and reliability, which are priceless.

When I built my own company, I learned that in the long run, the price list is the least important document. The cheapest supplier is useless if they disappear when a shipment is late or a batch has an issue. A true partner works with you to solve problems. Now, I ask potential manufacturing partners three questions:

- Can you show me your quality control process?

- What is your raw material traceability?

- What happens if there's a problem?

Their answers tell me everything. A great partner is proud to show you their processes. They can tell you where their brass comes from. They have a clear plan for when things go wrong. Look for that transparency and commitment to reliability. That is the foundation of a partnership that helps your business grow.

Conclusion

A frost-free sillcock is a simple device, but its quality is critical. Understanding how it works and what defines a superior product protects your clients, your reputation, and your bottom line.