How Can You Avoid Costly Leaks in Your Pipeline System?

A single, tiny leak can cause huge problems. It leads to product loss, safety risks, and expensive downtime, damaging your company's reputation and bottom line.

Avoiding leaks starts with smart design choices. Focus on three areas: selecting the right seal material for your application, ensuring perfect thread engagement, and using fittings with precision-machined sealing surfaces. These fundamentals prevent leaks before they start.

I remember a project with a client who manufactured chemical dosing systems. They were having a terrible time with field failures. Their units would work perfectly for a few weeks, then start leaking from multiple connection points. They were blaming the technicians for not tightening the fittings enough. I went to their site and took apart one of the failed fittings. The O-ring, which should have been soft and pliable, was hard and brittle. It had cracked. They had used a standard Buna-N O-ring for a system that was handling a mild solvent. The solvent slowly attacked the rubber. It's a classic example of how the smallest, most overlooked component can become the single biggest point of failure.

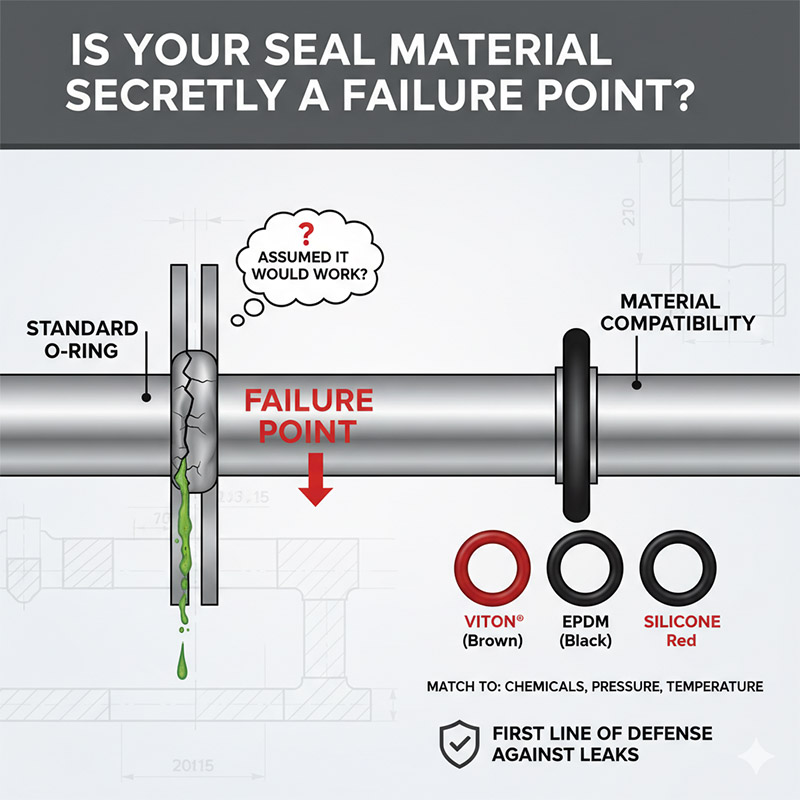

Is Your Seal Material Secretly a Failure Point?

You chose a standard O-ring, assuming it will work. But chemical incompatibility or extreme temperatures are causing it to swell or crack, creating a hidden path for leaks.

The key is material compatibility. Match your seal material (like Viton®, EPDM, or Silicone) to the specific chemicals, pressure, and temperature range of your system. This is your first line of defense against chemical degradation and leaks.

The O-ring is the unsung hero of many connections, but we often treat it like a simple commodity. This is a critical mistake. Every elastomer has a unique personality. It has chemicals it likes and chemicals it hates. For example, EPDM is fantastic for hot water and steam applications but will quickly get destroyed by petroleum-based oils. Buna-N (Nitrile) is the opposite; it's great for oils but weak against ozone and weather exposure. Viton® (FKM) is the premium option, offering broad chemical resistance and high-temperature performance, but it comes at a higher cost. As a designer, your job is to play matchmaker. You must look at your fluid compatibility chart and your expected temperature range and select the seal that won't just work on day one, but will continue to work for the intended life of the product. This proactive choice prevents 90% of seal-related leaks.

The Science of Sealing: Material Matters

-

### Chemical Compatibility This is non-negotiable. The seal material must be inert to the fluid it is sealing. Always check a chemical compatibility chart before specifying a seal.

-

### Temperature Range All elastomers have a specific operating temperature window. Extreme cold can make them brittle, while extreme heat can cause them to permanently deform or degrade.

| Seal Material | Excellent For | Poor For | Temp. Range (°C) |

|---|---|---|---|

| Buna-N (Nitrile) | Petroleum oils, water | Ozone, ketones, sunlight | -40 to 120 |

| EPDM | Hot water, steam, acids | Petroleum oils, solvents | -50 to 150 |

| Viton® (FKM) | Oils, fuels, acids, solvents | Ketones, amines | -20 to 200 |

| Silicone (VMQ) | Wide temps, water, ozone | Oils, strong acids | -60 to 225 |

Are Poorly-Made Threads Causing Your Connections to Weep?

You've tightened a fitting with a wrench until it won't budge. Days later, you see a slow, persistent weep. The connection feels tight, but it is not truly sealed.

Leaks often happen in the thread's "root," not the crest. Precision-cut threads, like NPTF (Dryseal), are designed to crush and form a metal-to-metal seal. Using quality fittings with clean, perfectly formed threads is essential.

Tapered threads, like the common National Pipe Thread (NPT), are designed to seal by interference. As you tighten the fitting, the male and female threads wedge together. However, with standard NPT threads, a tiny spiral gap remains at the root of the thread. This gap is why you must use a thread sealant or PTFE tape—to fill that void. But what if you could eliminate the void entirely? That's the idea behind NPTF, or Dryseal threads. The roots and crests of NPTF threads are designed to crush and deform during assembly, creating a complete metal-to-metal seal without any sealant. While sealant is still recommended to prevent galling, the thread form itself does the heavy lifting. The only way to get this level of precision is with modern CNC machining. Poorly made fittings with cast or roughly cut threads will never achieve this reliable, leak-free seal.

The Perfect Fit: Threads That Seal

-

### Standard vs. Dryseal Threads While they look similar, NPTF threads have a controlled design at the root and crest to create a metal-to-metal seal, making them inherently more resistant to leaks.

-

### The Role of Sealant On NPT threads, sealant is a gap-filler. On NPTF threads, sealant acts primarily as a lubricant to ensure the threads can fully engage without seizing (galling).

| Feature | Standard NPT Threads | Dryseal NPTF Threads |

|---|---|---|

| Sealing Mechanism | Thread flanks + sealant in gap. | Metal-to-metal seal at root/crest. |

| Sealant Required? | Yes, to fill the leak path. | No, but recommended for lubrication. |

| Reliability | Good (depends heavily on sealant). | Excellent (inherent in the design). |

| Typical Quality | Varies widely, common in cast parts. | Requires high-precision machining. |

Can a Microscopic Scratch on a Surface Cause a Massive Leak?

The fitting is brand new and the O-ring is correct. But the connection still fails a pressure test. A tiny, invisible flaw is sabotaging your entire assembly.

Yes, a microscopic flaw can cause a complete failure. A leak-proof seal depends on a flawless surface. The metal face an O-ring presses against must be perfectly smooth, as any scratch creates a leak path.

This applies to any fitting that uses a gasket or an O-ring to seal on a flat face, like a flange or a straight-thread port. The seal works by being compressed against a metal surface, filling in its microscopic imperfections. But if there is a scratch or tool mark on that surface, it creates a channel too deep for the elastomer to fill. It's like a tiny highway for fluid to escape. That's why engineers specify a "surface finish" for these critical faces, often measured by its roughness average, or Ra. A lower Ra value means a smoother surface. A typical surface off a CNC machine might be 64 Ra, but for a critical seal, a designer like Jacky might need to specify 32 Ra or even 16 Ra. Achieving these ultra-smooth finishes requires special tooling, controlled machining speeds, and sometimes post-machining processes like lapping or polishing. It's a level of detail that commodity fittings often ignore.

The Unseen Enemy: Surface Finish

-

### What is Surface Finish (Ra)? It's a measurement of the microscopic peaks and valleys on a metal surface. For sealing, smoother is always better.

-

### Why It's Critical An O-ring can't seal a scratch. The smoother the mating surface, the more contact area the seal has, and the more reliable the connection will be under pressure.

| Surface Finish (Ra µin) | Description | Typical Sealing Application |

|---|---|---|

| 125 | Standard Machined | General purpose, non-sealing faces. |

| 63 | Good Machined Finish | Low-pressure static seals. |

| 32 | Fine Machined Finish | High-pressure static O-ring seals. |

| 16 | Ground or Lapped | Dynamic seals (moving parts), metal seals. |

Conclusion

Preventing leaks is not about luck. It is about choosing the right seals, demanding precision threads, and specifying flawless sealing surfaces in your initial design.