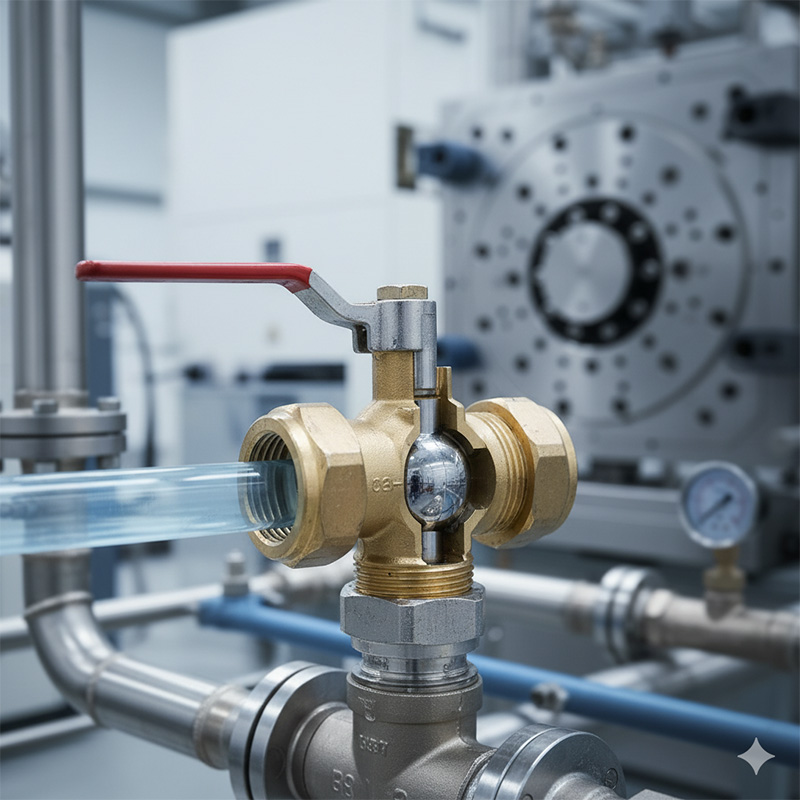

How Do You Know if Your Mold's Bypass Valve is Open or Closed?

Your mold temperature is unstable, causing defects. You suspect a flow issue, but the chiller seems fine. Is a hidden valve sabotaging your entire process?

To tell if a bypass valve is open or closed, you first need to identify its type. For quarter-turn valves, the handle's position is the key: it aligns with the pipe when open. For multi-turn valves, you must use indirect methods like checking for a temperature difference across the valve.

This takes me back to a molding shop I was visiting in the Midwest. They were making automotive interior parts and were plagued by a "ghost" that caused sink marks on a large part, but only on Mondays and Tuesdays. By Wednesday, the process would stabilize. They had swapped operators, checked the material, and calibrated the machine. Nothing worked. Frustrated, I started tracing the cooling lines from the mold back to the temperature control unit (TCU). Tucked away behind the unit was a bypass loop with a simple blue-handled ball valve. Someone on the weekend maintenance shift, thinking they were "helping," had cracked it open slightly to reduce the load on the pump. This small opening was diverting just enough chilled water away from the mold to cause cooling issues. Once we closed it, the problem vanished instantly. That little blue handle was costing them thousands of dollars in scrap every week.

Is the Handle's Position All You Really Need to Check?

You see the valve handle is aligned with the pipe. You assume it's fully open, but your mold's flow rate is still low. Are you being misled by the handle?

Yes, for a quarter-turn valve like a ball or butterfly valve, the handle's position is the primary indicator. A handle parallel to the pipe means open; perpendicular means closed.

But you should never assume. A worn-out or damaged valve can have a handle that moves, but the internal ball or disc does not. This gives you a false visual confirmation that can waste hours of troubleshooting time.

Let's dive deeper into these common valves. They are popular because they are simple, reliable, and quick to operate. A quarter-turn is all it takes to go from fully open to fully closed. This makes them perfect for on/off applications, like isolating a mold for a tool change. However, they are generally not designed for "throttling," or trying to finely control the flow by leaving them partially open. Leaving a ball valve half-open can cause turbulence and uneven wear on the seals.

When the Handle Lies to You

The biggest mistake is trusting the handle position without question. Over time, the connection between the external handle and the internal valve stem can strip or break, especially on cheaper valves. The handle might point to "open," but the internal ball is stuck closed. If you suspect this, don't just rely on the visual. Confirm flow with a downstream flow indicator or by feeling the temperature of the pipe. For critical lines, this is why training operators to use lockout tags is so important. It prevents someone from accidentally closing a valve that should be open.

| Valve Type | How it Works | Best Use Case in Molding |

|---|---|---|

| Ball Valve | A ball with a hole through it rotates to allow or block flow. | On/off isolation for mold cooling lines. |

| Butterfly Valve | A disc rotates inside the pipe to allow or block flow. | Larger diameter lines, like main chiller supply headers. |

What If Your Valve Has No Handle or the Handle Just Spins?

You find a big, round-handled valve on the main water line. You turn it and turn it, but you're not sure if it is open, closed, or somewhere in the middle.

This uncertainty is a real problem. With multi-turn valves like gate or globe valves, there's no quick visual cue. You need a reliable, indirect method to know for sure what's happening inside.

The best way is to use a non-contact infrared (IR) thermometer. Measure the pipe temperature just before the valve, and then just after it. If flow is happening, the temperatures will be nearly identical. If the valve is closed, the pipe after it will be much closer to the ambient air temperature.

Let's explore these indirect methods. They are your secret weapon for troubleshooting complex flow problems in a noisy factory.

Feeling the Flow with Temperature

This temperature trick is based on a simple principle: heat transfer. If your chilled water is 60°F (15°C) and the factory air is 80°F (27°C), a closed valve will act like a dam. The pipe after the valve will quickly warm up toward 80°F. If the valve is open, the constant flow of 60°F water will keep the pipe after the valve at 60°F. The greater the temperature difference between your process water and the ambient air, the more obvious this effect will be. It's a fast, safe, and surprisingly accurate way to confirm flow without ever touching the valve itself.

Using Your Other Senses

Don't forget the basics. In a quieter area, you can often hear the rush of water through an open valve. You can also place your hand on the pipe after the valve; you can sometimes feel a slight vibration from the turbulent flow. And finally, look downstream. Is there a flow indicator, like one of our sight glasses, on the line? If that indicator's spinner is moving, then you know for sure that the upstream valve is open.

| Diagnostic Method | How It Works | Best For Identifying... |

|---|---|---|

| Handle Position | A visual check of the handle's alignment with the pipe. | Open/closed status of quarter-turn valves. |

| IR Thermometer | Detects temperature differences caused by lack of flow. | Open/closed status of any valve type, especially multi-turn. |

| Flow Indicator | Visual confirmation of fluid movement downstream. | The absolute confirmation of flow, regardless of valve type. |

Conclusion

Knowing your valve's true status is fundamental to stable process control. Use handle position for quick checks on ball valves and an IR thermometer to be certain with any valve, protecting your mold and your production schedule.