What Makes a Flow Control System Truly Robust?

You meticulously design a system with quality parts. But unexpected failures, leaks, or vibration still occur, causing costly downtime and threatening your project's reputation.

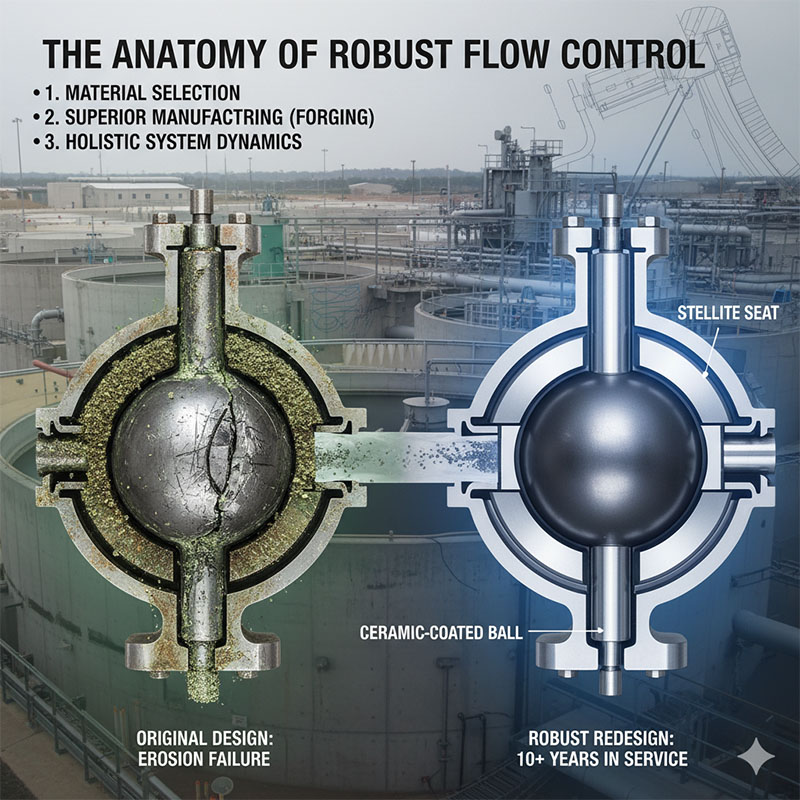

A truly robust system integrates three key elements: precisely matched material selection for the environment, superior manufacturing processes like forging for critical components, and a holistic design that accounts for system dynamics.

I once worked with a partner on a large municipal water reclamation project. They were experiencing rapid, unexplainable failures in their main shutoff valves. On paper, everything was correct—the pressure ratings were right, the valve type was standard for the industry. But the valves were failing in less than a year. I flew out to see the site. When we cut a failed valve open, the problem was obvious. The "reclaimed" water had fine, abrasive particulates in it that were acting like liquid sandpaper, completely eroding the soft seats and scoring the valve body. The original spec didn't account for wear resistance. We collaborated on a new solution: a valve with a hardened Stellite seat and a ceramic-coated ball. It cost more upfront, but it has now been in service for over a decade. It proved that a "robust" system isn't just about pressure; it's about deeply understanding the entire environment.

Is Simply Specifying "Stainless Steel" Enough to Guarantee Longevity?

You specify stainless steel for its corrosion resistance. Yet, you still find surface rust or, even worse, pitting and cracking, making you question your entire material strategy.

No, this is a dangerous oversimplification. The specific grade of stainless steel (e.g., 304, 316, Duplex) is critical. Choosing the wrong grade for the environment leads to premature and catastrophic failure.

As a designer, Jacky, you know that details matter, and this is a big one. The "stainless" family is broad. Grade 304 is a great general-purpose choice, but expose it to any chlorides (like saltwater, de-icing salts, or certain chemicals), and it will start to show rust and pitting. For those environments, you must upgrade to Grade 316, which contains Molybdenum for superior chloride resistance. For even more aggressive environments, like those in chemical processing or offshore oil and gas, we need to go further to Duplex stainless steels. These have a mixed microstructure that gives them incredible strength and resistance to stress corrosion cracking. Partnering with us means we help you look beyond the basic spec and select the exact alloy that provides true long-term strength for your specific application.

Matching the Grade to the Application

| Material Grade | Key Characteristic | Ideal Environment | Avoid In |

|---|---|---|---|

| SS304 | General purpose, good formability | Food equipment, architectural, fresh water | Any marine or chloride environment |

| SS316 | Excellent chloride resistance | Marine, pharmaceutical, chemical processing | High-stress, very high chloride applications |

| Duplex 2205 | Extreme strength & corrosion resistance | Oil & Gas, desalination, caustic chemicals | General purpose (cost prohibitive) |

Does It Matter if Your Valve Body is Forged or Cast?

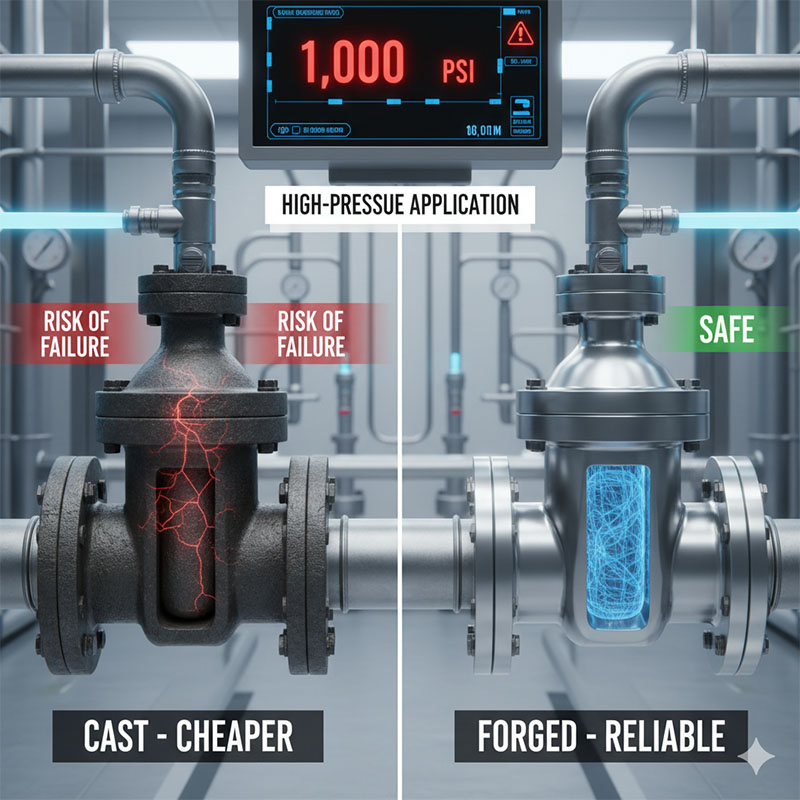

You need a component for a high-pressure application. A cast version is cheaper and readily available, but you have a nagging fear about hidden defects leading to failure.

Yes, critically. Forging creates a denser, more uniform grain structure, eliminating the risks of porosity and voids common in castings. This results in a mechanically stronger and more fatigue-resistant component.

This is a fundamental choice that impacts the ultimate strength of your system. A casting is made by pouring molten metal into a mold. While effective, this can trap tiny gas bubbles or impurities, creating internal voids (porosity). These hidden defects are weak points that can become the origin of a crack under pressure or vibration. Forging, on the other hand, takes a solid piece of metal and shapes it under immense pressure. This process refines the metal's internal grain structure, aligning it to the shape of the part. There are no hidden voids. For you as a designer, this means you get a part with superior tensile strength and fatigue resistance. For a critical, high-pressure flow control system, that isn't a small detail—it's the foundation of its safety and reliability.

Manufacturing Method Breakdown

-

### Casting Good for complex, non-critical shapes where cost is the primary driver. It offers design flexibility but comes with the inherent risk of internal defects.

-

### Forging Essential for high-pressure and high-stress applications. Provides maximum strength and reliability by creating a superior, uniform internal structure.

-

### Machining from Bar Stock Excellent for dimensional accuracy and good material integrity, but can be wasteful as it involves removing a lot of material. The grain structure is linear, not aligned to the part's shape.

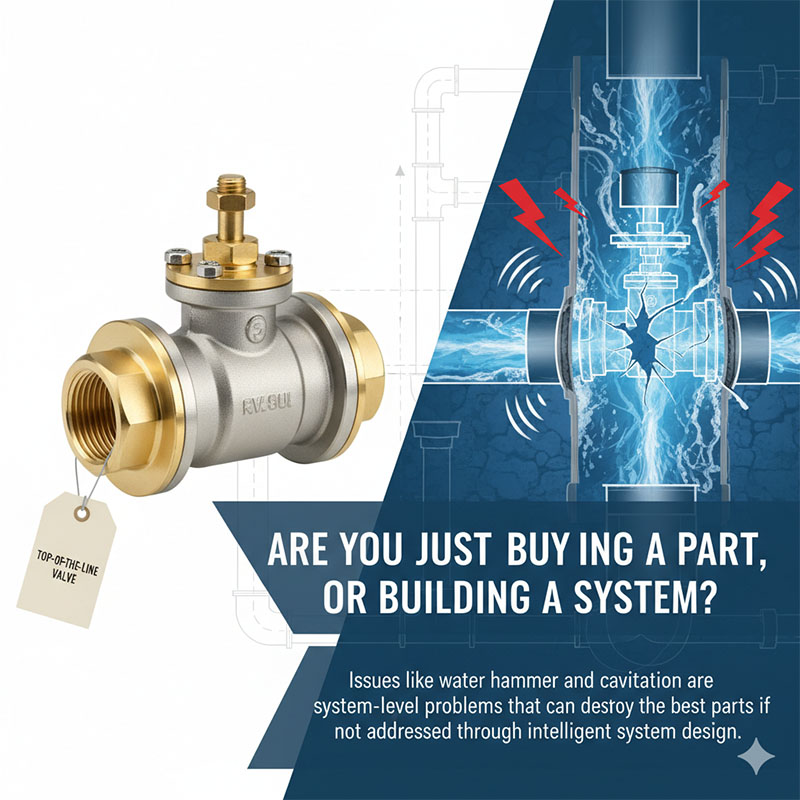

Are You Just Buying a Part, or Building a System?

You've chosen a top-of-the-line valve, but the system still experiences loud noises, vibration, or damaging pressure spikes. The problem persists despite using the "best" components.

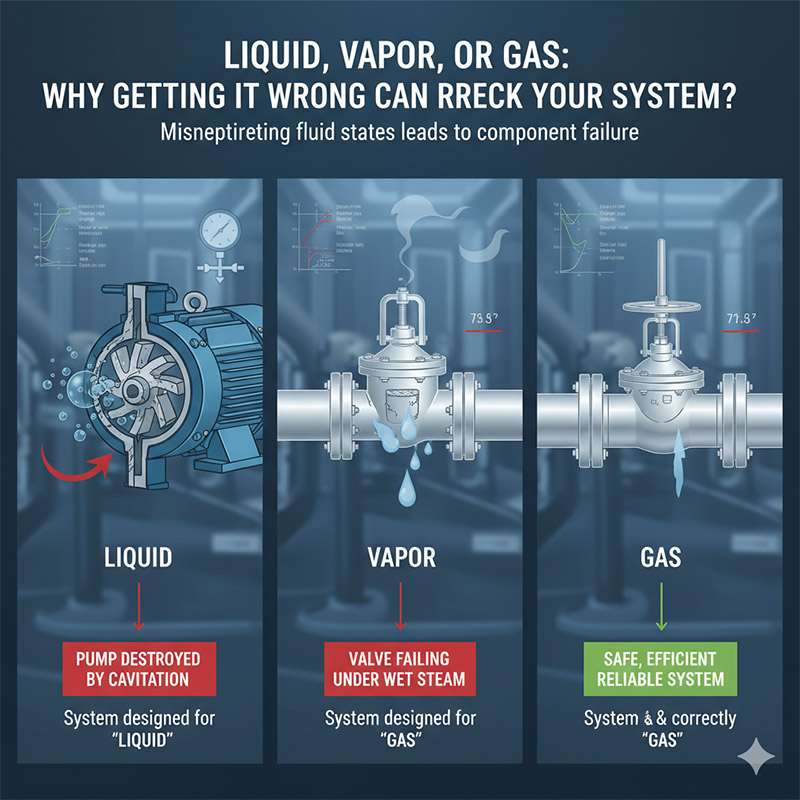

You must think beyond the component and analyze the system's dynamics. Issues like water hammer and cavitation are system-level problems that can destroy the best parts if not addressed through intelligent system design.

A flow control system is more than a collection of parts; it's a dynamic environment. When a valve closes suddenly, the moving column of water has nowhere to go, and its momentum converts into a massive pressure spike called water hammer. This shockwave can literally break pipes and destroy instruments. Similarly, a poor pressure profile can cause cavitation, where vapor bubbles form and implode, blasting metal from your valve's internals. A true partner helps you anticipate these issues. We can help you select a valve with a specific closing speed, or recommend a globe valve instead of a ball valve for better throttling control to prevent cavitation. By analyzing the entire system, we can help you build a system that is not only strong but also stable and quiet.

System Problems vs. Part Problems

| Symptom | Common Misdiagnosis | Likely System Cause |

|---|---|---|

| Loud Banging on Valve Closure | Faulty Valve | Water Hammer (System Design) |

| Rumbling/Gravel Noise | Defective Valve Internals | Cavitation (Pressure Drop Issue) |

| Valve Seat Erosion | Poor Quality Seat Material | Abrasive Media in the Fluid |

Conclusion

Building strong flow control systems is a collaborative effort. It’s about matching materials to the environment, choosing the right manufacturing process, and designing for the system as a whole.