How Do We Make Every Single Valve and Fitting Count?

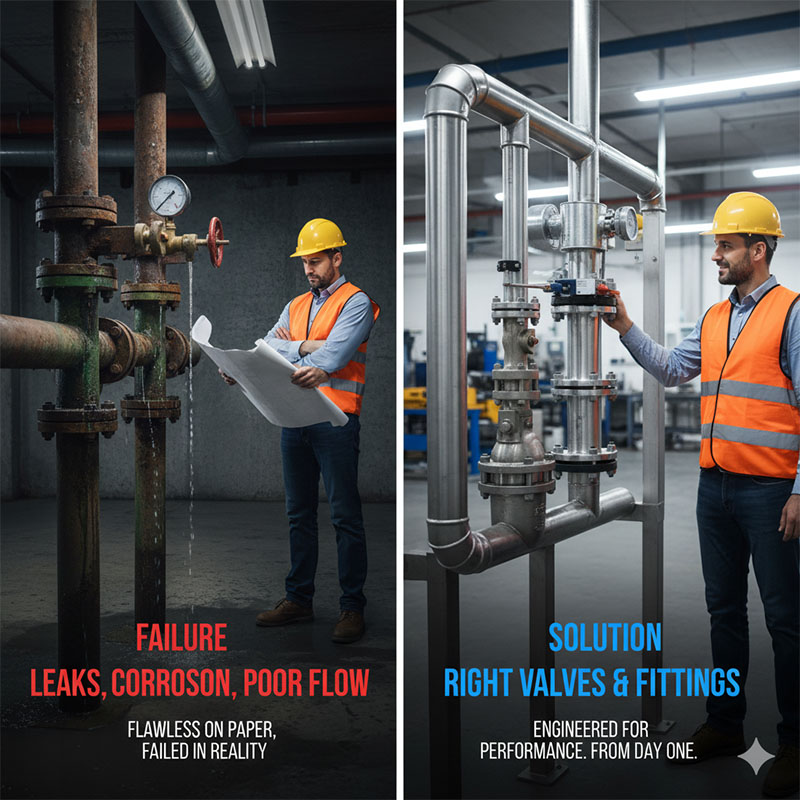

You've designed a perfect system on paper. But a single, seemingly insignificant fitting fails, causing a leak that shuts everything down and puts your project weeks behind schedule.

We make every part count by controlling the entire process with an obsession for detail. From verifying the raw metal's chemistry to pressure testing every finished piece, nothing is left to chance.

Years ago, I was considering a new supplier for some basic stainless steel fittings. Their price was incredible, almost too good to be true. I decided to fly out and visit their factory before placing a big order. It was a wake-up call. The place was disorganized, raw material bars were stored outside in the rain, and there was no real quality control station. I saw a worker checking a critical thread with a worn-out, beat-up caliper. I knew right then that I could never trust my clients' projects to that kind of operation. A low price is worth nothing if the process is broken. That visit reinforced my core belief: a quality part isn't an accident. It's the result of a quality process, every single time. Our factory is built on that principle.

Does Quality Really Start With a Simple Bar of Steel?

You receive a part that looks perfect, but it corrodes or cracks in the field. The provided material certifications feel worthless, and you have no way to verify the material's integrity.

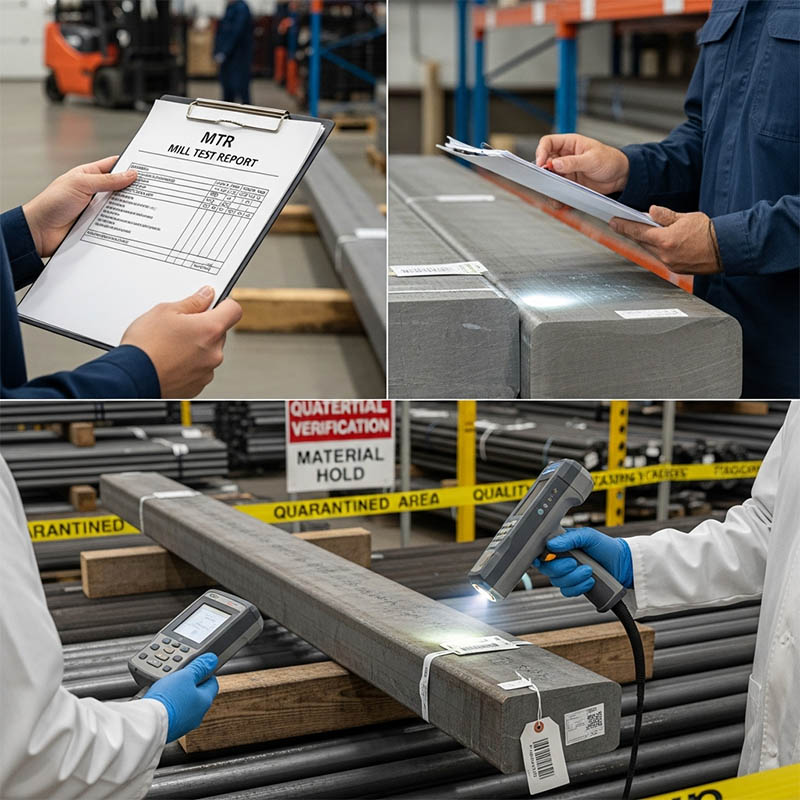

Yes, quality begins with 100% verifiable raw materials. We quarantine all incoming metal until its Mill Test Report (MTR) is verified, ensuring the chemical composition and mechanical properties match your exact specifications.

The entire manufacturing journey starts with a single piece of raw material, usually a long bar of steel or another alloy. If this starting point is flawed, every part made from it will be flawed. That’s why our process begins at the receiving dock. Every single batch of material arrives with a document called a Mill Test Report, or MTR. This is like the material's birth certificate, detailing its exact chemical makeup and the results of strength tests. But we don't just trust the paperwork. We use a handheld XRF (X-ray fluorescence) analyzer to double-check the alloy composition on the spot. This guarantees that the bar labeled "316 Stainless Steel" is actually 316 stainless steel. This step is non-negotiable for us. It prevents material mix-ups and ensures the part you designed, Jacky, has the exact corrosion resistance and strength you're depending on.

The Foundation: Material Control

-

### Quarantined Receiving No material hits the factory floor until it is cleared by our quality team. Each bundle is tagged and tracked from the moment it arrives.

-

### MTR Verification We meticulously review the MTR for every batch to ensure it meets international standards like ASTM or ASME for chemistry, tensile strength, and hardness.

-

### Physical Inspection & Analysis We visually inspect for any surface defects and use our XRF analyzer for positive material identification (PMI). This provides a final, foolproof layer of verification.

Is "Close Enough" Good Enough in Precision Machining?

You specify a component with tight tolerances, but parts from different batches don't fit together perfectly. This inconsistency points to a lack of control in the manufacturing process.

No. "Close enough" leads to leaks and failures. Our CNC machines are programmed to exact dimensions with tolerances measured in thousandths of an inch. Every critical dimension is checked with calibrated instruments.

Once the raw material is verified, it moves to our CNC machining centers. This is where a simple bar is transformed into a complex valve body or fitting. "CNC" stands for Computer Numerical Control, meaning the machine cuts the metal based on a precise digital design. For you as a designer, the most important concepts here are tolerance and surface finish. A critical dimension might be specified as 1.500 inches, with a tolerance of +/- 0.002 inches. This means the final part must be no larger than 1.502 and no smaller than 1.498 inches. Our process is designed to hold these tolerances consistently. Furthermore, for sealing surfaces, the smoothness, or surface finish, is key. We machine these surfaces to be exceptionally smooth to prevent damage to seals and O-rings, which is a primary cause of leaks. We achieve this with constant monitoring, sharp tooling, and a relentless focus on precision.

The Pillars of Precision Machining

| Control Element | Why It Matters | Our Standard |

|---|---|---|

| CAD/CAM Programming | Ensures the machine cuts the exact geometry of your design. | All programs are written and simulated by expert engineers. |

| Calibrated Metrology | Guarantees that the tools measuring the part are accurate. | All calipers, micrometers, and gauges are calibrated on a strict schedule. |

| In-Process Inspection | Catches any deviation from the standard as it happens. | Operators check critical dimensions on the first part, and every few parts after. |

Can You Trust a Part That Hasn't Been Tested?

You install a new valve, and it leaks the moment you pressurize the system. The component is dead on arrival, forcing an immediate, costly shutdown and replacement.

Absolutely not. A part without a final test is just a piece of metal with a question mark on it. Every single valve we assemble undergoes rigorous hydrostatic and pneumatic pressure testing.

Creating perfect components is only half the battle. They have to be assembled and tested correctly. Assembly is performed in a designated clean area to prevent any contamination from dirt or metal chips that could compromise a seal. But the final and most crucial step is testing. We believe that batch testing—where you only test a few items from a large run—is an unacceptable risk. That's why every single valve we make goes through a two-part pressure test. First is the hydrostatic shell test. We fill the valve with water and pressurize it to 1.5 times its working pressure rating to ensure the body itself is structurally sound. Second is the pneumatic seat test. We apply low-pressure air to the valve and submerge it in water to look for even the tiniest bubbles, which would indicate a leak in the seal. A valve doesn't get our name on it until it passes both tests with zero leaks.

Our Testing Gauntlet: The Final Guarantee

-

### Clean Assembly Parts are cleaned and carefully assembled by trained technicians using specified lubricants and calibrated torque wrenches to ensure seals are seated correctly.

-

### 100% Pressure Testing Not 1 in 10, not 1 in 100. Every valve is tested. This is the only way to guarantee a zero-leak performance when it arrives at your facility.

-

### Traceability Each tested valve is serialized, allowing us to trace it all the way back to the specific batch of raw material it was made from.

Conclusion

Making every part count isn't a slogan; it's a systematic process of control, precision, and verification that we follow every day, from raw steel to the finished, tested product.