Should You Use Stainless Steel or Brass Fittings for Your Mold Cooling Lines?

You’re tired of seeing messy, green corrosion on your mold’s cooling fittings. A tiny drip from a cheap fitting just caused a two-hour production stop to prevent damage to the mold.

The choice depends on your specific application and coolant type. Generally, stainless steel offers superior corrosion resistance and is essential for aggressive coolants or medical parts. Brass is a cost-effective and reliable workhorse for general-purpose molding applications with standard treated water.

I learned this lesson on a project for an automotive client. To save a few hundred dollars on the bill of materials, the original tool shop used standard brass quick-disconnect fittings on a mold we designed. The problem was that the client's facility used a specific type of glycol in their water system to prevent freezing. Within six months, we started getting calls about intermittent leaks. When I finally went to the plant, I saw it firsthand. The brass fittings were weeping coolant. The glycol had leached the zinc out of the brass alloy, a process called dezincification, making them porous and weak. We replaced every single fitting with stainless steel, and the problem vanished instantly. That tiny "savings" upfront cost the client thousands in downtime and my own time in troubleshooting. It proved to me that the fitting material is not just a detail; it's a critical system choice.

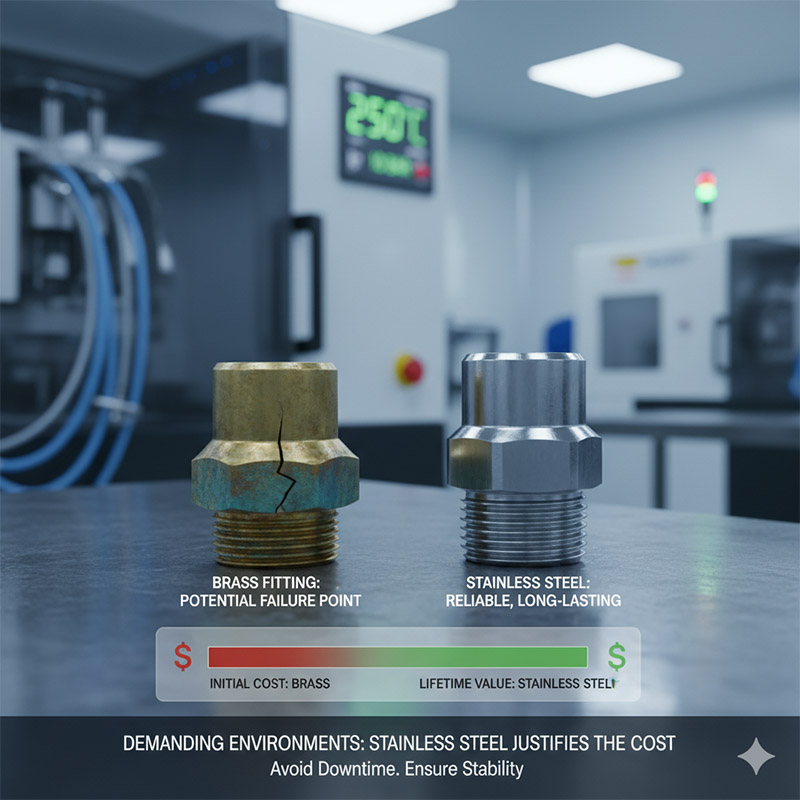

When Does Stainless Steel's Durability Justify the Higher Cost?

You want to use the best components, but your budget is tight. The price difference between stainless steel and brass fittings seems huge, making you question if the extra cost is really worth it.

That higher upfront cost is an investment against future failure. Stainless steel is the clear winner and a necessity when dealing with aggressive coolants, high temperatures, or applications where contamination is not an option, like medical molding.

Use stainless steel to avoid costly downtime and ensure process stability in demanding environments. Its strength and resistance to corrosion and chemical attack mean you can install it and forget it, whereas a brass fitting might be a ticking time bomb.

Let’s dive deeper into why stainless steel commands a premium. First is corrosion resistance. Stainless steel contains chromium, which forms a passive, invisible layer of chromium oxide on the surface. This layer instantly reforms when scratched, providing continuous protection against rust and chemical attack. This is vital when using deionized (DI) water, which is very aggressive and will literally pull minerals out of brass, or when using certain types of glycol-based coolants. Second is strength. Stainless steel is significantly stronger and harder than brass. This means the threads are less likely to get stripped or damaged during installation and removal, a common issue in busy molding shops. Finally, there's cleanliness. In medical or food-grade molding, you cannot risk leaching minerals like lead (present in some brass alloys) or copper into the cooling circuit, which could potentially contaminate the molding environment. Stainless steel is inert, making it the only real choice for these critical applications.

Stainless Steel vs. Brass: A Head-to-Head Comparison

| Feature | Stainless Steel (e.g., 304 or 316) | Brass |

|---|---|---|

| Corrosion Resistance | Excellent. Self-passivating surface protects against rust and chemicals. | Good to Fair. Vulnerable to dezincification and attack from aggressive fluids like DI water. |

| Upfront Cost | Higher. Can be 2-4 times the cost of brass. | Lower. Very cost-effective for general applications. |

| Strength & Durability | Very High. Resists thread stripping and physical damage. | Moderate. Softer material, threads can be damaged more easily. |

| Chemical Compatibility | Excellent. The default choice for DI water, glycols, and harsh chemicals. | Limited. Best for standard, treated water systems. |

| Cleanliness | Excellent. Inert and non-leaching, ideal for medical/food grade. | Fair. Can leach lead or zinc into the system. Not for cleanroom use. |

Is Brass Ever the Smarter Financial Choice for Cooling Fittings?

Your purchasing manager is pushing back on the cost of stainless steel fittings for every mold. You start to wonder if you're over-specifying and wasting money on non-critical projects.

Absolutely. Over-engineering is its own form of waste. For a huge number of molding applications, brass is not just acceptable; it's the smarter, more economical choice.

When your process uses a standard, well-maintained closed-loop system with treated water, and you aren't molding for a highly sensitive industry, brass fittings perform reliably and save you money. Their excellent thermal conductivity and lower cost make them the workhorse of the industry for a reason.

The key is to understand where brass fits. Think about molding standard consumer products like toy parts or electronic housings. These molds often run in facilities with professionally treated tower or chiller water. The water has rust inhibitors and biocides that make it relatively non-aggressive. In this environment, a quality brass fitting will last for years without issue. Brass also has slightly better thermal conductivity than stainless steel, though in the context of a small fitting, this performance difference is negligible. The real benefit is the cost savings. When you are building a manifold with 20 in/out ports, choosing brass over stainless steel can save a significant amount of money that can be better used elsewhere in the mold build. The trick is to be honest about your operating conditions. If you choose brass, you must commit to using clean, treated water. Using brass fittings with poor quality water is asking for them to get clogged with rust and scale.

Decision Checklist: Which Material Do You Need?

| Decision Point | Choose Stainless Steel If... | Choose Brass If... |

|---|---|---|

| 1. What is your coolant? | You use Deionized (DI) Water or an aggressive Glycol mixture. | You use standard, chemically treated city or tower water. |

| 2. What is the part application? | The part is for medical, food, or another cleanroom environment. | The part is for general consumer, industrial, or automotive use. |

| 3. What is the mold temperature? | You are running high-temperature materials requiring hot oil or high-pressure water. | You are running standard materials below 120°C (250°F). |

| 4. What is the environment? | The mold will be in a corrosive environment or requires frequent wash-downs. | The mold is in a typical, climate-controlled molding facility. |

Conclusion

Choosing between stainless steel and brass fittings isn't about good versus bad; it's about using the right tool for the job. Analyze your coolant, application, and budget to make a smart choice that ensures both reliability and cost-effectiveness.