How Do We Turn Raw Metal into Trusted Precision Parts?

You receive a shipment of gleaming new parts, but a nagging doubt remains. You can't see the internal quality, leaving you to hope that they perform as promised.

Our factory builds trust into every part through a transparent, three-stage process: We meticulously verify all raw material, utilize a complete precision machining ecosystem, and perform rigorous final validation.

I often invite clients to walk through our factory. They expect to see a typical machine shop. What usually surprises them is the quiet, methodical atmosphere. It's less like an old-school factory and more like a laboratory. They see operators checking parts, technicians analyzing material, and detailed reports at every station. A tour is the best way to show that "trust" isn't a slogan for us; it's a series of deliberate, verifiable actions. Since you can't be here in person today, let me walk you through our process, exactly as I would if you were standing next to me.

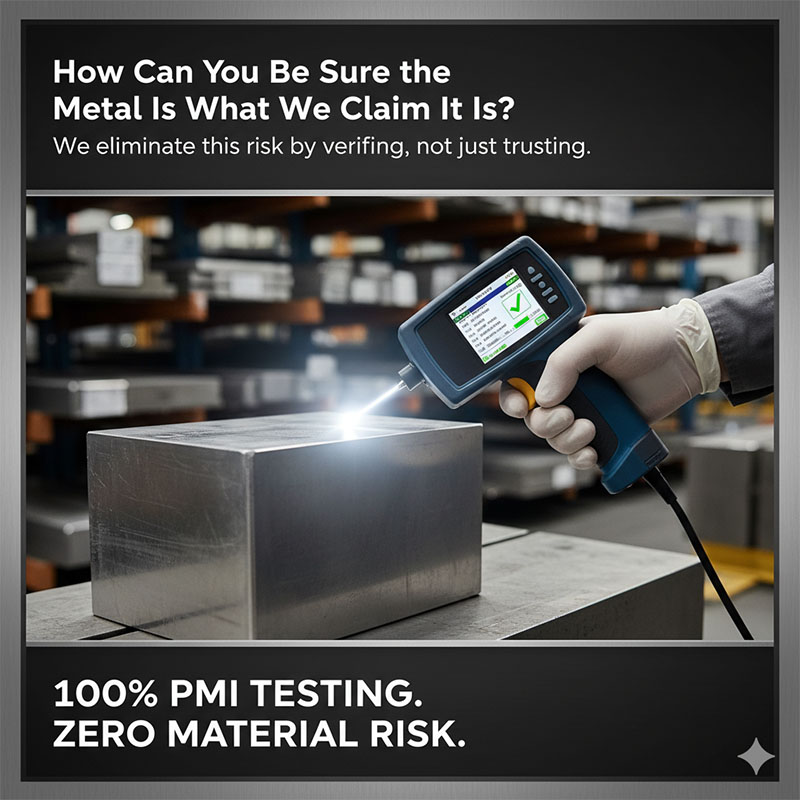

How Can You Be Sure the Metal Is What We Claim It Is?

You approve a design based on a specific alloy, but you secretly worry about material substitution. A supplier mix-up could lead to catastrophic corrosion or mechanical failure later on.

We eliminate this risk by verifying, not just trusting. We use Positive Material Identification (PMI) to test 100% of our raw materials upon arrival, confirming their chemical composition before they ever enter production.

It all starts when a truck delivers a new batch of stainless steel or alloy bars. Every batch comes with a Mill Test Report (MTR), a certificate from the steel mill. Most suppliers file this paper and are done. We consider it Step Zero. The first thing we do is pull out our X-ray fluorescence (XRF) analyzer. This is a handheld device that looks a bit like a ray gun from a science fiction movie. We place it directly on the metal bar, pull the trigger, and within seconds, it gives us a precise chemical breakdown of the material. This tells us if the 316L Stainless Steel we ordered is truly 316L. This step is non-negotiable. I once heard a story from an engineer about a batch of fittings that failed because a supplier's employee had accidentally mixed bars of 304 and 316 stainless steel. That simple mistake cost millions. Our PMI process makes that kind of error impossible.

Trust vs. Verify: The Material Check

-

### The Mill Test Report (MTR) This is the material's "birth certificate." It's our baseline for what the material should be, but we treat it as a claim that needs to be proven.

-

### Positive Material Identification (PMI) This is our "DNA test." Using XRF technology, we confirm the MTR is accurate, ensuring the exact alloy composition required for your application is what we use.

| Standard Practice (Trust) | MoldAll Practice (Verify) |

|---|---|

| Accepts the MTR paperwork. | Scans every raw material batch with PMI. |

| Risks material mix-ups. | Eliminates the risk of material mix-ups. |

| Quality is assumed. | Quality is confirmed with data. |

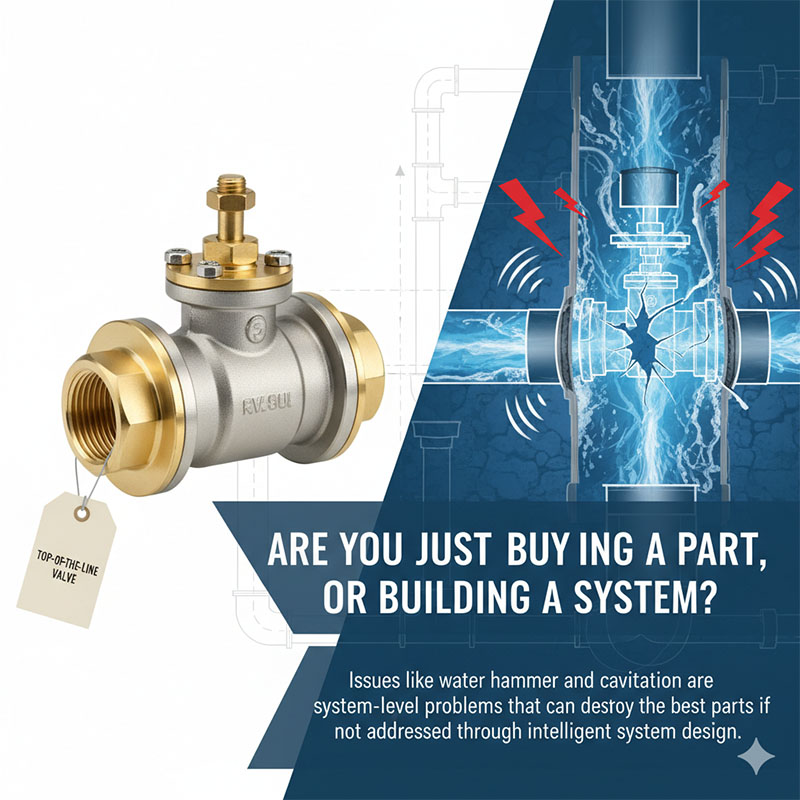

What Makes Our Machining a True Precision 'Ecosystem'?

You've received parts that are technically "in tolerance" but vary widely from part to part. This inconsistency creates frustrating problems during automated assembly and affects product performance.

We achieve consistent precision by treating machining as an ecosystem. It’s a combination of state-of-the-art CNC machines, premium tooling, and a climate-controlled environment, all working in harmony.

Anyone can buy a CNC machine. The real secret to consistent precision isn't just the machine itself, but the entire environment around it. This is what I call the "machining ecosystem." First, the foundation is a stable environment. Our machine shop is climate-controlled to maintain a constant temperature. Why? Because metal expands and contracts with even small temperature changes. A part machined on a hot afternoon will be dimensionally different from one machined on a cool morning. Second, we invest heavily in tooling. We don't use cutting inserts until they are completely worn out. We change them frequently to ensure every cut is as clean and precise as the first. Finally, our experienced programmers use advanced CAM software to create toolpaths that minimize stress on the part and the tool, resulting in superior surface finishes. For you, Jacky, this means the 10,000th part you receive will be a virtual clone of the first.

The Three Pillars of Our Machining Ecosystem

-

### The Machine & Environment Our multi-axis CNC machines are housed in a temperature-stable facility to eliminate thermal variation, a major source of inconsistency in precision work.

-

### The Tooling & Programming We use premium cutting tools and sophisticated CAM software. This allows for smoother cuts, better surface finishes, and less tool wear, all leading to higher part-to-part consistency.

| Standard Machine Shop | Our Precision Ecosystem |

|---|---|

| Variable shop temperature. | Stable, climate-controlled facility. |

| Uses tools until failure. | Proactively changes tools for consistency. |

| Basic machine programming. | Advanced CAM software for optimal toolpaths. |

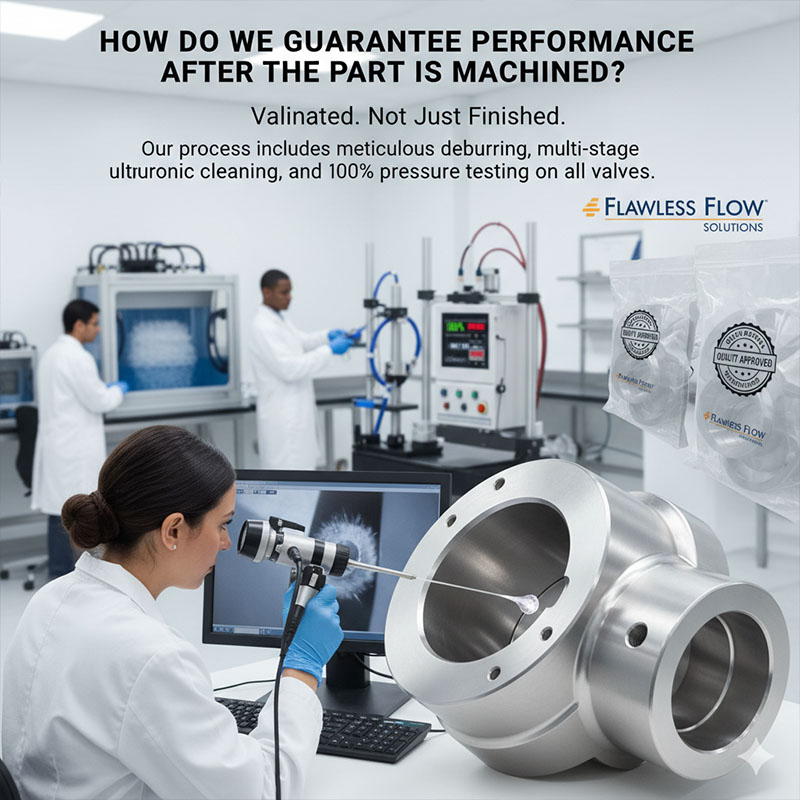

How Do We Guarantee Performance After the Part Is Machined?

A finished part looks perfect, but a tiny, hidden burr shreds an O-ring during assembly. This "minor" oversight leads to leaks, product recalls, and a complete loss of trust.

A part isn't finished until it’s validated. Our process includes meticulous deburring, multi-stage ultrasonic cleaning, and 100% pressure testing on all valves to ensure flawless real-world performance.

The machining process, by its very nature, can create microscopic sharp edges called burrs. To the naked eye, the part looks perfect. But under a microscope, these burrs are like tiny razor blades. Left on a fitting, they can slice a rubber O-ring during assembly, creating a leak path that might not show up for weeks or months. This is why our post-machining process is so intensive. Every part goes through a careful deburring stage, often done by hand under magnification. After that, they are submerged in a multi-stage ultrasonic cleaning bath. This process uses high-frequency sound waves to blast away any residual cutting fluid, metal fines, and contaminants from every surface and internal passage. Finally, for any assembled part like a valve, the job has one more step: it gets hooked up to a test rig for a full hydrostatic pressure test. We don’t sample; we test every single one.

The Final Steps to Flawless Performance

-

### Deburring & Cleaning We use both manual and automated processes to remove all burrs, followed by an ultrasonic cleaning cycle to ensure parts are surgically clean.

-

### 100% Function Testing Every valve we assemble is subjected to a pressure test that exceeds its stated working pressure. A pass/fail report gives you documented proof of its integrity.

| Basic Finish | Our Validated Finish |

|---|---|

| Quick tumble deburring. | Manual inspection and deburring. |

| Simple solvent wash. | Multi-stage ultrasonic cleaning. |

| Batch spot-check for leaks. | 100% pressure testing on all valves. |

Conclusion

Our factory builds trust by showing our work. By verifying materials, perfecting our machining ecosystem, and validating every final part, we deliver precision you can not only see but trust.