Is a Simple Leaky Fitting Threatening Your Entire Production System?

You're losing production time and risking equipment damage from leaky connections. A small drip from a cheap adapter seems minor, until it causes a slip hazard or shorts out expensive electronics.

High-performance adapters, often called fire adapters for their ruggedness, create a secure, leak-proof seal. They ensure operational continuity by eliminating a common point of failure, keeping your systems running safely and efficiently.

Jacky, this makes me think of a close call we had years ago. We were running a brand-new, very expensive multi-cavity tool for a medical device. It had complex cooling channels and was positioned right over the machine's central control unit. A technician used a cheap, cast aluminum camlock fitting on one of the main water lines. Overnight, a hairline crack formed. The slow drip landed squarely on the control board. The resulting short circuit fried the board, taking down a $500,000 machine for three days. We lost the cost of that cheap fitting a thousand times over. It proved to me that the smallest connections can cause the biggest failures.

What Exactly Makes a Fire Adapter "High-Performance"?

You see two adapters that look similar, but one costs twice as much. It's tempting to save money on what seems like a simple fitting, but then you face constant leaks and premature failures.

A high-performance adapter uses superior materials and precision manufacturing. Forged metals, not cast, provide immense strength. Precision-machined threads and locking mechanisms ensure a perfect fit, while high-grade gaskets create a durable, leak-proof seal.

As a designer, you know that materials and manufacturing methods are everything. A "high-performance" label isn't just marketing; it's a promise of reliability rooted in engineering. A cast part has a porous, crystalline structure that can hide internal voids and weaknesses. Forging, on the other hand, aligns the grain structure of the metal, making it incredibly strong and resistant to cracking under pressure or from impact. This is why critical components on airplanes are forged, not cast. The same principle applies to a fitting that's holding back hundreds of PSI of water pressure just inches from your valuable mold or machine electronics.

Forged vs. Cast: A Designer's View

| Feature | Cast Adapter (Standard) | Forged Adapter (High-Performance) |

|---|---|---|

| Manufacturing | Molten metal poured into a mold. | Solid metal shaped under high pressure. |

| Material Strength | Lower, prone to hidden cracks. | Extremely high, dense, and uniform. |

| Pressure Rating | Good for low-pressure only. | Excellent for high-pressure systems. |

| Durability | Brittle, can crack if dropped. | Tough, can withstand impacts. |

| Cost | Low | Higher |

How Does a Connection Fitting Directly Ensure Operational Continuity?

Your team is constantly chasing down small, nagging issues. A minute to tighten a leak here, five minutes to replace a bad gasket there. Each small interruption adds up to hours of lost production every month.

Operational continuity comes from eliminating unplanned stops. A high-performance adapter is designed to be installed and forgotten. Its robust construction resists vibration, pressure spikes, and wear, preventing leaks and failures that cause unscheduled downtime.

Think about the concept of Overall Equipment Effectiveness (OEE). It's a measure of your plant's true productivity. Every time a machine stops for a preventable reason, your OEE score drops. A leaky fitting is a classic example of a preventable failure. While a 5-minute stop doesn't seem like much, it breaks the rhythm of production. The operator loses focus, the process temperature might fluctuate, and the first few parts after restarting might be scrap. A reliable adapter contributes directly to a higher OEE score by maximizing availability. It’s a component that pays for itself not by what it does, but by what it prevents: the constant, profit-killing interruptions that plague so many shops. It transforms a weak link into a strong, reliable connection.

How Do You Select the Right Adapter for Your Specific Application?

You need to specify a connection for a new mold design. There are dozens of types and materials. Choosing the wrong one can lead to corrosion, leaks in the field, or connection difficulties for the production team.

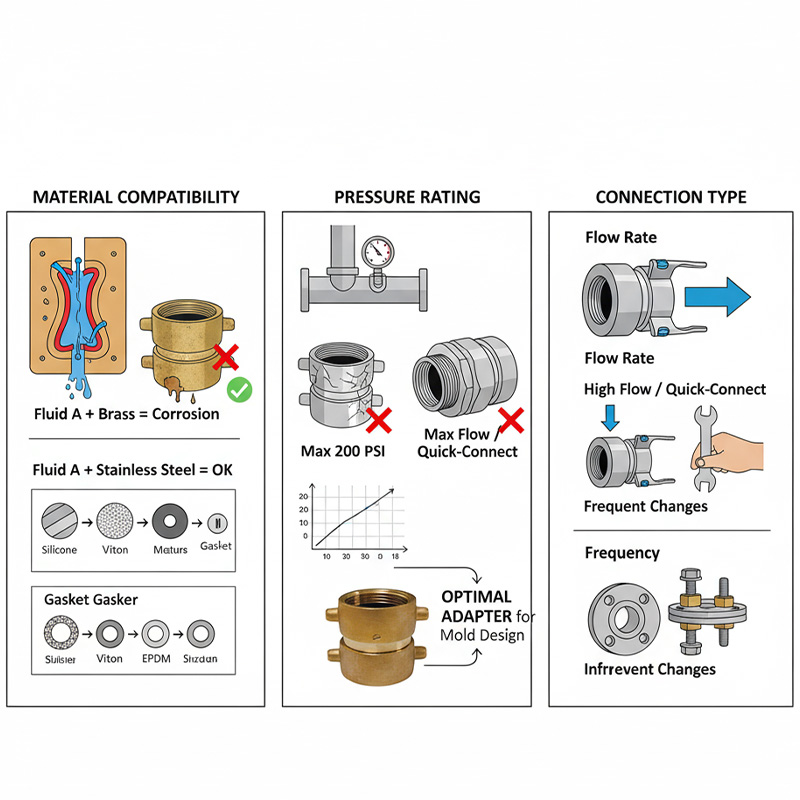

To select the right adapter, you must match its specifications to the system's demands. Your three primary criteria are Material Compatibility (fluid vs. metal/gasket), Pressure Rating, and Connection Type, based on the required flow rate and frequency of connection.

For a designer like you, Jacky, selection is a methodical process. This is where you can add huge value by preventing future problems right on the drawing board. Don't just specify "1-inch hose connector." Be precise. Your selection process should be a simple checklist that considers the environment and the task. For example, a large-volume cooling line for a structural foam mold needs a different solution than a small line on a high-speed packaging mold. One might prioritize massive flow (Storz), while the other needs a compact, quick-disconnect ability (Camlock). Getting this detail right makes the production team's life easier and ensures the system you designed works flawlessly.

Quick Selection Guide for Mold Designers

| Selection Criteria | Key Question to Ask | Common Options & Recommendations |

|---|---|---|

| 1. Pressure & Temp | What is the max operating pressure and temperature? | Check the adapter's specs. Ensure its rating is at least 25% above the system's max pressure. |

| 2. Media/Fluid | What fluid will it carry (water, glycol, oil)? | Brass: Good for water. Stainless Steel: For corrosive fluids or cleanrooms. Aluminum: Lightweight. |

| 3. Gasket Material | Is the fluid compatible with the seal? | NBR: Standard for water/oil. Viton (FKM): For chemicals and high temps. EPDM: For glycol-based coolants. |

| 4. Connection Type | How often will it be connected/disconnected? | Threaded (NPT): Semi-permanent. Camlock: Frequent use, fast. Storz: Large diameter, very fast quarter-turn. |

Conclusion

High-performance adapters are not just fittings; they are engineered components that guarantee system integrity. By choosing the right one, you prevent failures, ensure continuity, and protect your most valuable assets.