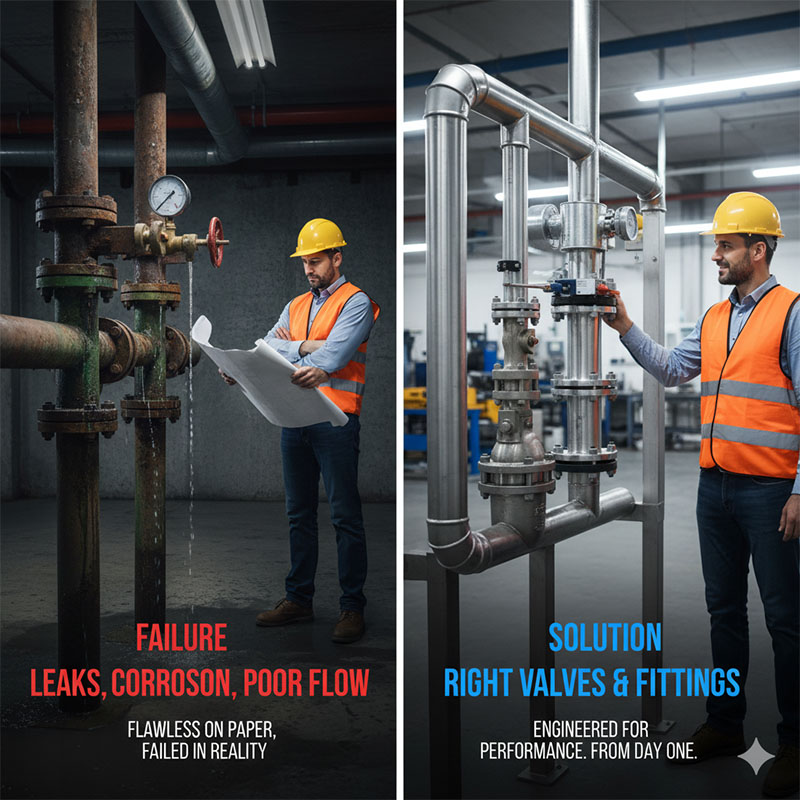

Are Your Valves and Fittings a Maintenance Nightmare in Disguise?

You’ve designed an innovative mold, but the maintenance team dreads working on it. Seemingly simple tasks like replacing a seal take hours, causing production delays and frustration for everyone.

Yes, your design choices for valves and fittings directly impact maintenance time. By focusing on accessibility, standardization, and strategic component isolation from the start, you can transform a complex mold into one that is remarkably easy and fast to service, minimizing costly downtime.

I remember walking through a partner factory once and seeing a beautiful, complex mold sitting idle on a bench. I asked the manager what was wrong. He sighed and said, "A ten-cent O-ring failed in a cooling line." I thought, "That's a quick fix." He just shook his head. The designer had tucked the fitting so deep inside the assembly to make it 'compact' that they had to disassemble half the mold to reach it. A 5-minute fix had turned into a 4-hour job. That day, I learned that a great design isn't just about how it works; it's also about how it's fixed. Designing for maintenance isn't a chore; it's your secret weapon for maximizing uptime.

Is Your 'Compact' Design Impossible to Service?

You've created an incredibly space-efficient mold by tucking components tightly together. But when a valve starts dripping, the technician can't even get a wrench on it.

This common oversight turns routine maintenance into a major project. Good design isn't just about fitting everything in; it's about ensuring every serviceable part can be reached and replaced with standard tools, without needing to dismantle the entire system to get to it.

When I review a new mold design, I don't just look at the flow paths and mechanics. I mentally try to repair it. I imagine a technician in a hurry, with greasy hands, trying to loosen a specific fitting. Can they see it? Can they get a wrench on it and have enough room to turn it? Too often, designers are so focused on the digital model that they forget the physical reality of maintenance. The single biggest time-saver you can give a maintenance team is clear access. This is achieved by thinking about service from the very beginning of the design process.

Mind the Wrench Swing

It’s a simple concept, but it's often forgotten. A fitting doesn't just occupy its own space; it needs a "service envelope" around it. Before you place a valve or fitting, visualize the tool needed to install and remove it. Ensure there is enough clearance not just for the tool itself, but for the arc it needs to swing through to tighten or loosen the part. This small consideration prevents a technician from having to use a modified or special tool, saving immense time and frustration.

The Power of Manifolds

Instead of running a dozen individual hoses all over the mold, consider using a manifold. A manifold block centralizes your fluid connections into one organized location. This has huge maintenance benefits. It dramatically reduces the number of potential leak points, makes troubleshooting incredibly easy (all connections are in one place), and simplifies hose replacement. A well-designed manifold looks clean and professional, and it's a dream for any maintenance team to work on.

| Design Approach | Designer-Focused (Compact) | Maintenance-Focused (Serviceable) |

|---|---|---|

| Priority | Smallest possible footprint | Ease of access and repair |

| Component Placement | Tightly packed components | Components with clear access paths |

| Result | 2-hour repair for a simple leak | 10-minute repair for the same leak |

| Technician Feedback | Frustration and delays | Gratitude and efficiency |

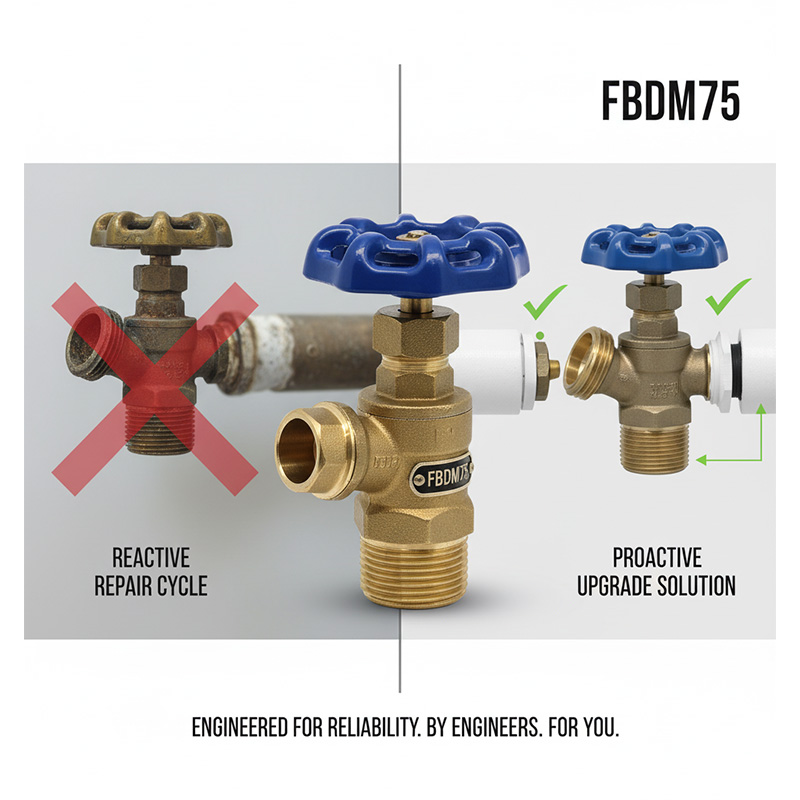

Are Your Custom Fittings Creating Unnecessary Downtime?

You specified a unique, high-performance valve for a non-critical line. Now that valve has failed, and the machine sits idle while the factory waits three days for a replacement part.

Relying on non-standard parts creates a fragile supply chain and extends downtime. The solution is to standardize components and build in system isolation with simple shut-off valves for every critical component.

In my trading company, we had one client who was brilliant but loved to "optimize" every single part. His molds had 15 different types of small fittings because each was technically the 'perfect' choice for its exact location. But when a machine went down, his maintenance team would scramble, trying to find the one specific fitting they needed. We helped him develop a "standard parts list" with just three types of fittings that covered 95% of his needs. His maintenance times dropped overnight. It wasn't about finding the perfect part for the job; it was about finding a very good, standard part that was always in stock. This shift in thinking is fundamental to designing for low maintenance.

Establish a "Standard Parts Library"

Work with your production and maintenance teams to create a pre-approved list of valves and fittings. For example, decide to use only 1/4" and 3/8" NPT brass fittings for all standard cooling lines. This simple act has a domino effect: the purchasing department buys in bulk, saving money. The maintenance team stocks fewer parts, simplifying inventory. Most importantly, when a fitting fails, the technician knows they have the replacement on hand. Standardization is the most powerful tool for reducing mean time to repair (MTTR).

The Magic of the Isolation Valve

Place a simple ball valve on the inlet and outlet of any major sub-circuit or serviceable component, like a hydraulic actuator or a special cooling channel. This is called an isolation loop. If that component leaks or fails, a technician can simply close the two ball valves, isolate it from the rest of the system, and perform the repair. The rest of the mold can often continue to operate, or at the very least, a full system drain and refill is avoided. It's a tiny upfront cost for a massive downstream benefit.

| Component Strategy | Non-Standardized / Custom | Standardized with Isolation |

|---|---|---|

| Mean Time To Repair (MTTR) | High (hours or days) | Low (minutes or hours) |

| Inventory Cost | High (many unique parts) | Low (fewer parts in bulk) |

| Technician Training | Complex (many part types) | Simple (few familiar parts) |

| Overall Uptime | Lower | Higher |

Conclusion

Designing for maintenance is not an afterthought; it is a core principle of excellent engineering. Prioritize access, standardize components, and use isolation valves to make your designs famously reliable.