How Can Upgrading Your Sight Glasses Directly Lower Maintenance Costs?

You're replacing the same sight glasses over and over. It's a nuisance maintenance job that interrupts production. This recurring cost of parts and labor is quietly draining your budget.

Upgrading to high-quality borosilicate glass with correctly matched gaskets reduces failures drastically. This move lowers costs by cutting labor for replacements, cleanup from spills, and expensive production downtime.

Jacky, your question about ROI brings back a very specific memory. We had this one hydraulic power unit that we nicknamed "the Friday Failure." It had a cheap, plastic sight glass that would get cloudy and brittle from the heat and oil. It seemed to fail every other Friday afternoon, right when we were trying to finish a run. A technician would have to stop what he was doing, drain some oil, replace the part, and clean up the mess. One day, I sat down and did the math. The ten-dollar part was costing us over $150 every time it failed between labor, lost oil, and machine downtime. That's when I realized we weren't saving money at all; we were just paying for our mistake in small, painful installments.

How Much Are Cheap Sight Glasses Really Costing You in Labor and Materials?

You see a $10 sight glass and think it's a bargain. But then you're constantly ordering replacements and paying a technician to install them. These small, frequent costs add up fast.

The real cost of a cheap sight glass includes the part, the technician's hourly wage for the replacement time, and the price of any lost fluid. That $10 part can easily cost $100 in total maintenance expenses every time it fails.

As a designer, you know that the price tag isn't the whole story. You need to think in terms of Total Cost of Ownership (TCO). A cheap part feels like a win on the initial Bill of Materials (BOM), but it creates a long-term maintenance headache. You have to account for the direct costs associated with every single failure. This includes the labor—and skilled labor isn't cheap. You pull a maintenance technician off a critical job to replace a simple sight glass. That's time lost. You have to stock more replacement parts, which ties up money in inventory. And let's not forget the cost of lost hydraulic oil or coolant every time one lets go. When you put all these numbers on a spreadsheet, the "bargain" part is often the most expensive option over the life of the machine.

TCO Showdown: Cheap vs. Quality Sight Glass (2-Year Period)

| Cost Factor | "Cheap" Soda-Lime Glass | Quality Borosilicate Glass |

|---|---|---|

| Initial Part Cost | $10 | $50 |

| Failures in 2 Years | 8 (once per quarter) | 1 (hypothetically) |

| Labor Cost per Failure | $50 (1 hour @ $50/hr) | $50 (1 hour @ $50/hr) |

| Lost Fluid per Failure | $15 | $15 |

| Total Cost of Failures | 8 x ($50 + $15) = $520 | 1 x ($50 + $15) = $65 |

| Total 2-Year TCO | $10 (part) + $520 (failures) = $530 | $50 (part) + $65 (failure) = $115 |

How Does a Failed Sight Glass Lead to Catastrophic Unplanned Downtime?

A simple sight glass shatters, and your machine stops. Now, an entire production line is idle, waiting for a fix. You're missing deadlines and losing thousands of dollars every hour.

A failed sight glass causes unplanned downtime for replacement and cleanup. If a reservoir drains completely before anyone notices, it can take a critical machine offline for hours, erasing an entire shift's profit.

The indirect costs of failure are always much larger than the direct ones. I've seen it happen. A sight glass on a central hydraulic system fails, the pump runs dry, and it seizes up. Now, it's not a one-hour fix. You're down for the rest of the day, maybe longer, waiting for a new pump. The cost of that lost production is staggering. Every hour a multi-million-dollar injection molding machine or CNC center sits idle, you're losing hundreds or even thousands of dollars in potential revenue. That doesn't even account for the chain reaction. The parts from that machine are needed for assembly. Now that department is standing around. You might have to pay for expedited shipping to your customer to make up for the delay. As the designer, specifying a robust component from the beginning is your first line of defense against these catastrophic, cascading failures.

The Ripple Effect of a "Small" Failure

- Lost Production Revenue: The primary cost. If a machine generates $500/hour in value, an 8-hour stoppage costs $4,000.

- Idle Labor: The machine operator and potentially downstream assembly workers are being paid to wait.

- Schedule Disruption: Your whole production schedule gets thrown off, causing logistical chaos.

- Scrap Generation: Restarting a process after a long stop often produces bad parts until the parameters stabilize.

- Reputation Damage: Missing a deadline can damage the trust you have with a client.

Isn't Upgrading Your Sight Glass Also a Major Safety Improvement?

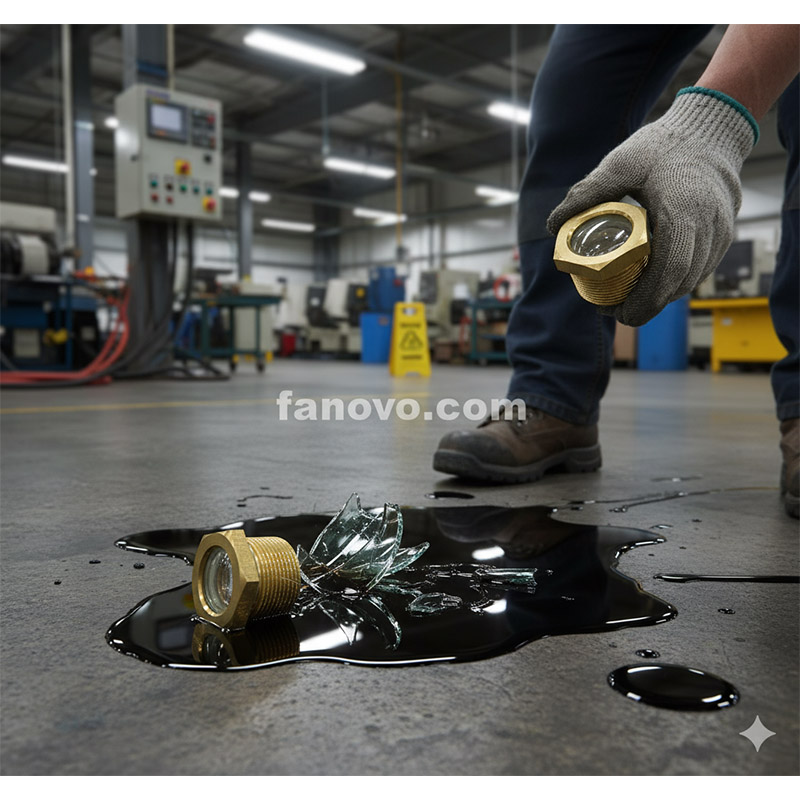

A sight glass shatters, spilling hydraulic oil all over the floor. This is now a severe slip hazard for your team. You're also facing environmental clean-up problems and potential compliance issues.

Absolutely. Upgrading to a durable, properly specified sight glass is a critical safety measure. It prevents dangerous spills, protecting employees from slip-and-fall injuries and helping you maintain a clean and compliant workplace.

The ROI of safety is harder to quantify on a spreadsheet until something goes wrong. We talked about the cost of lost oil, but what about the cost of a person slipping in that oil? A serious injury can lead to worker's compensation claims, lost time, and a negative impact on team morale. Then there is the environmental aspect. In many places, a large oil spill is a reportable event. You have the cost of absorbent materials, the proper disposal of hazardous waste, and potentially even fines from environmental agencies. All of this from one failed component. By designing with high-quality, shatter-resistant borosilicate glass, you are engineering that risk out of the system. You are making a proactive choice to protect your people and the environment. This kind of risk mitigation is one of the most valuable things a designer can provide. It's an investment that doesn't just pay back in money, but in peace of mind.

Conclusion

Upgrading your sight glasses offers an undeniable ROI. It lowers direct maintenance costs, prevents expensive downtime, and mitigates serious safety risks. It is an investment in reliability that pays for itself.