Why Are High-Quality Valves More Critical Than Ever Before?

You're designing advanced systems, but component failures continue to cause setbacks. The standard valves that worked for years are now becoming a source of unreliability and inefficiency.

Modern industries operate with tighter tolerances, harsher chemicals, and higher automation. High-quality valves are no longer just for shut-off; they are essential for precise control, system safety, and predictive maintenance in these demanding environments.

I remember consulting for a biotech company a few years back. They were developing a new process for creating pharmaceuticals that required incredibly precise temperature and pH control. They initially built their pilot system using standard, off-the-shelf diaphragm valves. It was a disaster. The valves couldn't respond fast enough to the automated control system's commands, causing wild swings in the process variables. The generic seals were also degrading from the complex cleaning agents they used. They were losing entire batches of product, worth hundreds of thousands of dollars. We worked with them to spec in high-performance, actuated globe valves with specialized seals. It was a complete transformation. Their process became stable, their yields went up, and they finally had a reliable system. It showed me that in modern industry, the valve isn't just a gatekeeper; it's a precision instrument.

Why Aren't Yesterday's "Good Enough" Valves Sufficient Today?

You're using valves that have been industry standard for decades. Yet, they struggle to keep up with faster, more precise automated systems, leading to process inefficiencies and control issues.

Modern processes demand more than just "on" or "off." They need precise modulation, faster response times, and resilience to more aggressive media, all of which exceed the capabilities of older, general-purpose valve designs.

The world of manufacturing has changed. A decade ago, a valve's main job in many systems was simply to open or close a line. Today, that same valve might be connected to a sophisticated PLC (Programmable Logic Controller) that adjusts its position ten times a minute to maintain a perfect flow rate. As a designer like you, Jacky, you're being asked to build systems that are faster, more efficient, and produce a higher quality product. This puts immense pressure on every component. A valve that was "good enough" for manual operation is now a bottleneck in an automated system. Its slow response time or lack of precision creates variability, and variability is the enemy of quality and efficiency in modern production. The demands have evolved, so our components must evolve too.

The New Demands on Valve Performance

| Old Expectation (c. 2000) | New Requirement (Today) | Impact on Design |

|---|---|---|

| Simple On/Off Control | Precise Flow Modulation | Requires control valves, not just shutoff valves. |

| Manual or Slow Actuation | High-Speed, Automated Response | Needs powerful actuators and positioners. |

| Basic Chemical Resistance | Resistance to Aggressive & Mixed Media | Requires specialized alloys and polymers. |

| Scheduled Maintenance | Predictive, Condition-Based Monitoring | Necessitates integrated sensors and data output. |

How Do "Smart" Valves Prevent Catastrophic Failures?

A critical valve fails without warning, shutting down your entire line. The cost of downtime and emergency repair is enormous, and there was no way to see it coming.

By integrating sensors, "smart" valves provide real-time data on their own health. They can report on wear, torque, and cycle count, allowing you to predict a failure and schedule maintenance before it happens.

This is one of the biggest leaps forward in our industry. For generations, we operated on a reactive maintenance model: a valve works until it breaks, then you fix it. The next step was scheduled maintenance: you replace the seals every 12 months, whether they need it or not. Both are inefficient. A "smart" valve changes the game entirely. It has built-in sensors that can measure things like the torque needed to open or close it. If that torque value starts to slowly increase over weeks, it's a clear sign that the seals are wearing out or that scale is building up. This data is sent to your plant's control system, which can automatically generate a work order to service that specific valve during the next planned shutdown. You're no longer guessing; you're using data to prevent failure. It transforms maintenance from a costly emergency into a planned, efficient activity.

Predictive vs. Reactive Maintenance

-

### From Downtime to Uptime Predictive maintenance allows a shift from unplanned, catastrophic failures to scheduled, low-impact service. This maximizes plant uptime and production output.

-

### Data-Driven Decisions Smart valves provide the hard data needed to optimize your maintenance budget. You can focus resources on the valves that actually need attention, rather than performing unnecessary routine replacements. This is crucial for large facilities with thousands of valves.

Is Material Science Now More Critical Than Ever for Valves?

You specified "corrosion-resistant" material, but it's still failing. The complex chemical cocktails and high temperatures of modern processes are pushing standard materials beyond their limits.

Yes, absolutely. The move toward more intense processes means that generic materials like 304/316 stainless steel are often no longer sufficient. Specialized alloys and engineered polymers are now essential for ensuring safety and longevity.

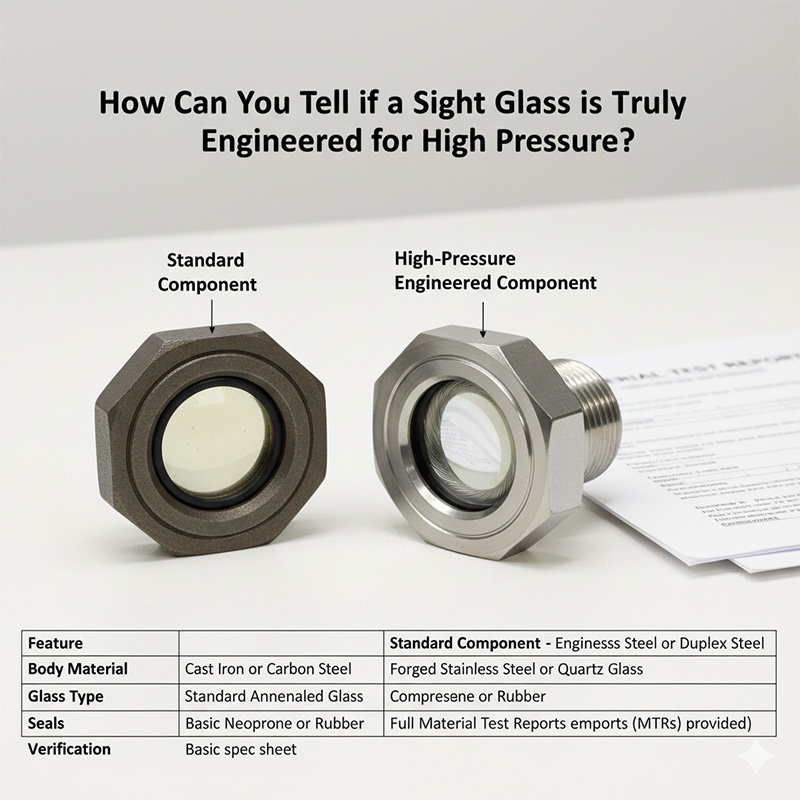

The operating envelope for valves has expanded dramatically. A food processing plant might now be using much more aggressive sanitation chemicals. A battery plant is handling highly corrosive lithium compounds. An oil refinery is operating at higher temperatures and pressures to increase efficiency. In all these cases, the standard "go-to" materials might not be enough. This is where deep material expertise becomes critical. You might need to move from 316 stainless steel to a super-austenitic grade like AL-6XN to handle high chloride concentrations. Or, for extreme chemical resistance, you might need a valve body fully lined with PFA, a type of Teflon. For high-wear applications, seat materials have evolved from simple elastomers to tough engineered polymers like PEEK. Choosing the right material is no longer just a suggestion; it is the most important decision for ensuring the safety and reliability of the entire system.

The operating envelope for valves has expanded dramatically. A food processing plant might now be using much more aggressive sanitation chemicals. A battery plant is handling highly corrosive lithium compounds. An oil refinery is operating at higher temperatures and pressures to increase efficiency. In all these cases, the standard "go-to" materials might not be enough. This is where deep material expertise becomes critical. You might need to move from 316 stainless steel to a super-austenitic grade like AL-6XN to handle high chloride concentrations. Or, for extreme chemical resistance, you might need a valve body fully lined with PFA, a type of Teflon. For high-wear applications, seat materials have evolved from simple elastomers to tough engineered polymers like PEEK. Choosing the right material is no longer just a suggestion; it is the most important decision for ensuring the safety and reliability of the entire system.

Matching Advanced Materials to Modern Challenges

| Industrial Challenge | Standard Material Risk | High-Performance Solution |

|---|---|---|

| High Chloride/Seawater | Pitting in SS316 | Duplex Stainless Steel, Super-Austenitic Alloys |

| Abrasive Slurries | Erosion of metal seats | Ceramic components, Hardened Alloy Trim |

| Concentrated Acids/Bases | Rapid corrosion of all metals | PFA/PTFE Lined Valves, Hastelloy |

Conclusion

In today's fast-paced industries, high-quality valves are no longer just passive components. They are active, essential assets for ensuring precision, safety, and a competitive edge in your operations.