What's the best way to understand refrigerant and AC components?

Struggling with complex AC system designs? A small mistake in one component can lead to system failure. This guide breaks down the essential parts for you simply and clearly.

Refrigerant and AC components are the core parts of any cooling system. They work together in a closed loop to move heat from inside a space to the outside. Key parts include the compressor, condenser, evaporator, and expansion valve, which circulate a special fluid called refrigerant.

Understanding how these parts fit together is the first step to mastering your designs. You need to see the full picture to appreciate how a small change in one area affects everything else. I've learned that the hard way over the years. This knowledge will not only prevent costly errors but also help you innovate. Let’s dive into the details and see how each component plays its critical role.

How Do Compressors and Condensers Work Together?

Is the relationship between the compressor and condenser confusing you? Misunderstanding their teamwork can lead to major flaws in your AC design. Let's make their distinct roles perfectly clear.

The compressor is the heart of the system, pumping and pressurizing the refrigerant gas. The condenser then receives this hot, high-pressure gas and cools it down, turning it back into a liquid. This process releases the heat absorbed from inside your space to the outside air.

Let's look deeper at how this partnership creates the foundation for cooling. The compressor does the heavy lifting, and the condenser handles the heat exchange. It's a simple, powerful cycle. I remember working on a project where we were designing a new housing for a scroll compressor. The goal was to reduce vibration and noise. We had to carefully consider the material properties and the mold design to achieve the tight tolerances needed. A tiny error in the draft angle could have made the part impossible to eject from the mold.

Compressor Types

The type of compressor you choose impacts efficiency and cost. Each has its own best use case.

| Compressor Type | Best For | Key Design Consideration (for Molds) |

|---|---|---|

| Reciprocating | Residential units, lower cost | Housing needs to withstand high vibration. |

| Scroll | High-efficiency residential & commercial | Complex internal geometry requires sliders. |

| Rotary | Small, quiet applications (e.g., RVs) | Tight tolerances for internal components. |

Condenser Design

Similarly, the condenser's design is vital. Air-cooled condensers are common in residential units and use a fan to blow air over coils. Water-cooled condensers are more efficient but are complex and usually found in large commercial systems. The design of the plastic fan blades and shrouds is key for airflow, and getting that mold right is a big challenge.

What Role Does the Evaporator Play in Cooling?

Does the evaporator's function seem like a mystery? If you don't grasp how it works, your entire AC design could fail. Let's uncover its simple but essential job.

The evaporator coil is where the real cooling magic happens. It absorbs heat from the indoor air as the cold, low-pressure liquid refrigerant flows through it. This process causes the refrigerant to boil and turn into a gas, creating the cold air that gets blown into your room.

To understand the evaporator, you have to think about heat exchange. Its job is to pull heat out of the air. The design of its fins and tubes is critical for maximizing this process. More surface area means better heat absorption. For a product and mold designer like you, the plastic components surrounding the evaporator are just as important. The drain pan, for example, must be designed with the correct slope to prevent water from pooling and causing leaks or mold growth.

To understand the evaporator, you have to think about heat exchange. Its job is to pull heat out of the air. The design of its fins and tubes is critical for maximizing this process. More surface area means better heat absorption. For a product and mold designer like you, the plastic components surrounding the evaporator are just as important. The drain pan, for example, must be designed with the correct slope to prevent water from pooling and causing leaks or mold growth.

Plastic Components in the Evaporator Unit

Material selection is key for parts around the evaporator because they are exposed to constant moisture and cool temperatures.

| Component | Common Material | Reason | Mold Design Tip |

|---|---|---|---|

| Drain Pan | Polystyrene (PS) | Good water resistance and low cost. | Ensure a slight angle is molded in for proper drainage. |

| Fan Blower | Polypropylene (PP) | Flexible, durable, and resists stress cracking. | Balance the mold for uniform filling to avoid wobble. |

| Casing | ABS | High impact strength and good aesthetic finish. | Plan for vents and mounting points in the mold design. |

I once had a client whose product was failing because the drain pan, which we didn't design, kept cracking. We discovered the original designers used the wrong material, one that became brittle at low temperatures. A simple material choice made all the difference. That's why deep component knowledge is so important.

Why is the Expansion Valve So Important?

Ever looked at a tiny expansion valve and dismissed its importance? This small part failing can cause a complete system breakdown. Let's explore why this little component is so powerful.

The expansion valve, or metering device, acts as a gatekeeper. It controls the amount of liquid refrigerant entering the evaporator. By creating a pressure drop, it rapidly cools the refrigerant just before it absorbs heat, maximizing the cooling effect. It's the key to system efficiency.

Think of the expansion valve as the fine-tuning knob of the AC system. Too much or too little refrigerant flow into the evaporator, and the system won't cool properly. It can even damage the compressor. While the valve itself is often a specialized metal part, its integration with the system involves many molded components, like brackets and connectors. A secure fit is absolutely crucial.

Think of the expansion valve as the fine-tuning knob of the AC system. Too much or too little refrigerant flow into the evaporator, and the system won't cool properly. It can even damage the compressor. While the valve itself is often a specialized metal part, its integration with the system involves many molded components, like brackets and connectors. A secure fit is absolutely crucial.

Types of Metering Devices

Different systems use different types of devices to control refrigerant flow.

- Thermostatic Expansion Valve (TXV): This is a smart valve. It has a sensing bulb that measures the temperature at the evaporator outlet. It then adjusts the refrigerant flow to match the cooling load. This makes it very efficient.

- Capillary Tube: This is a much simpler solution. It's just a long, thin copper tube with a fixed diameter. It's cheap and reliable but not as efficient as a TXV because it can't adjust to changing conditions. You'll find these in smaller, less expensive units like refrigerators.

When designing the layout, you have to ensure there is proper access for servicing these parts. We often design plastic access panels with snap-fit features. The challenge is making the snap-fits durable enough for repeated use without breaking. We use finite element analysis (FEA) to simulate the stress on these features before we even cut the mold steel.

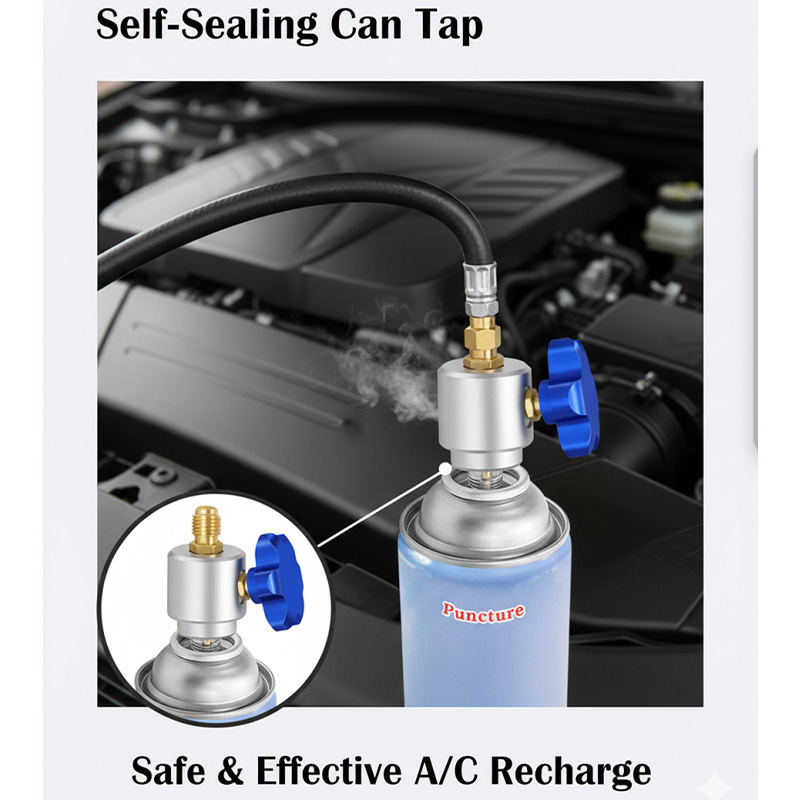

How Does Refrigerant Tie Everything Together?

Do you ever wonder how all these separate parts become a cooling system? The refrigerant is the lifeblood that connects them. Let's see how this special fluid makes everything work.

Refrigerant is a chemical compound that continuously cycles through the AC components. It changes between a liquid and a gas, absorbing heat from your indoor space and releasing it outside. Without this fluid constantly circulating and changing state, there would be no cooling at all.

! An infographic showing the refrigerant cycle through all AC components

An infographic showing the refrigerant cycle through all AC components

The magic of refrigerant lies in its properties. It has a very low boiling point, which allows it to turn from a liquid to a gas at low temperatures, absorbing a lot of heat in the process. Then, when it's compressed, its boiling point rises, allowing it to release that heat and turn back into a liquid easily. This cycle repeats over and over.

The Evolution of Refrigerants

The type of refrigerant used has changed over the years due to environmental concerns. Understanding this is important for modern product design.

| Refrigerant Type | Common Name | Key Fact |

|---|---|---|

| CFCs | Freon-12 | Phased out due to ozone depletion. Now illegal in new systems. |

| HCFCs | R-22 | Better than CFCs, but still damages the ozone. Also being phased out. |

| HFCs | R-410A | Does not deplete the ozone, but is a greenhouse gas. Next to be replaced. |

| HFOs | R-1234yf | New generation with low global warming potential. Used in new cars. |

When designing AC components, you have to consider their compatibility with the refrigerant being used. The seals, gaskets, and even some plastic parts must resist chemical breakdown from the specific refrigerant and the oils mixed with it. I've seen systems fail because a designer specified a rubber O-ring that wasn't compatible with R-410A. It seemed like a small detail, but it led to a massive recall.

Conclusion

Understanding the compressor, condenser, evaporator, expansion valve, and refrigerant is key. Mastering these basics will help you design better, more efficient products and avoid costly mistakes in your projects.