What Should Global Buyers Know Before Sourcing Valves and Fittings from Overseas?

Sourcing overseas seems cheap, but you're worried about quality and delays. A single mistake in communication or quality can wipe out all your initial cost savings and ruin a project.

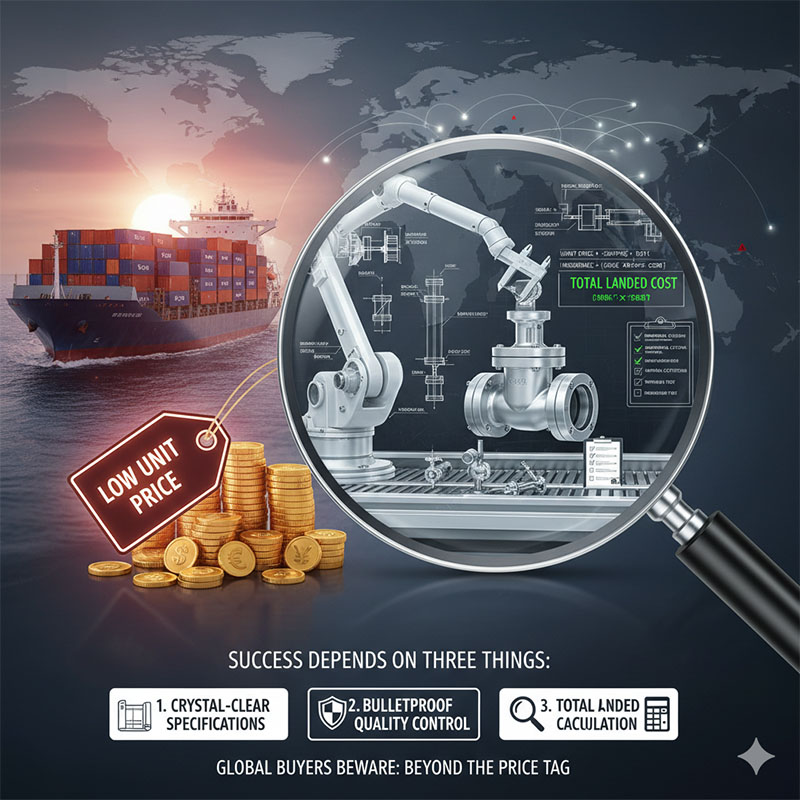

Success depends on three things: providing crystal-clear specifications, having a bulletproof remote quality control plan, and calculating the Total Landed Cost, not just the attractive unit price.

I'll never forget a client who came to me after getting badly burned. He ran a company that built hydraulic power packs. He found an overseas supplier online offering ball valves that looked identical to his usual ones but at half the price. It seemed like a no-brainer. I cautioned him, but the deal was too tempting. A few weeks after he installed them in his systems, the calls started coming in. The O-rings inside the valves were not compatible with standard hydraulic fluid; they were swelling and failing, causing massive, messy leaks. The downtime and clean-up costs were a nightmare for his customers. In the end, those "cheap" valves cost him and his clients ten times what he had "saved." It was a hard lesson for him: when you source globally, the price tag is the least important number if the specifications and quality aren't right.

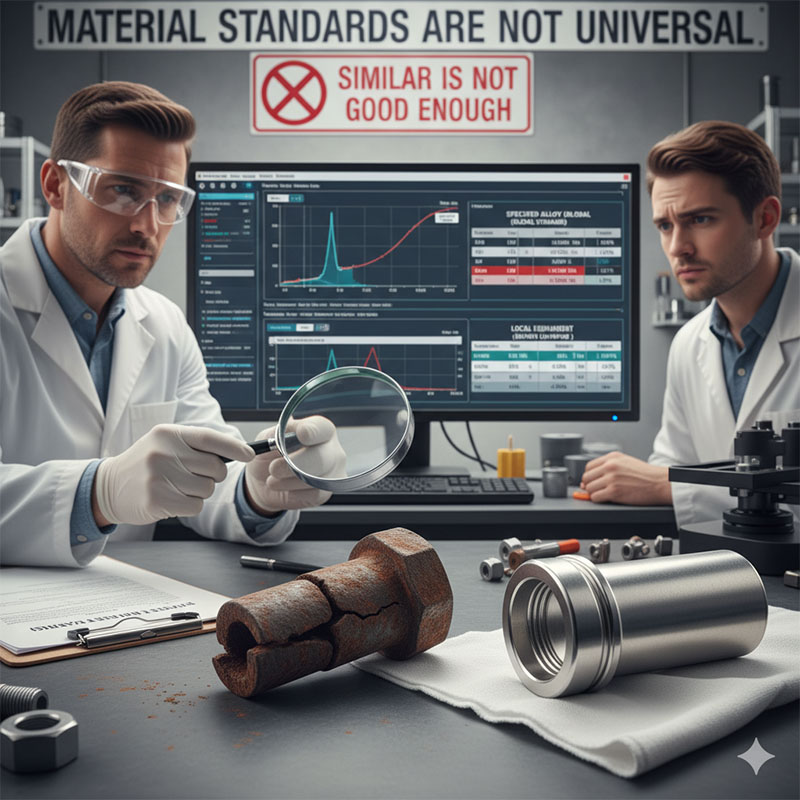

Is a "Similar" Material Specification Good Enough for Your Project?

Your overseas supplier says they have a "local equivalent" material that's much cheaper. Accepting it is a tempting way to lower costs, but you feel like you're taking a gamble.

It is absolutely not good enough. Material standards are not universal. A "similar" alloy might lack a tiny percentage of a key element that is critical for corrosion resistance or strength, leading to premature failure.

As a designer, Jacky, you would never accept "similar" for a critical plastic resin in one of your electronic housings. The same rigor must apply to metal. The word "brass" or "stainless steel" is dangerously vague. There are hundreds of different alloys, each engineered for a specific purpose. For example, C360 "Free-Cutting Brass" is great for machining, but C377 "Forged Brass" has far better corrosion resistance for applications like refrigeration. An uninformed supplier might substitute the C360 because it's cheaper and easier to get. It will look identical, but it might fail in the field six months later. To prevent this, you must demand compliance with an international standard (like ASTM, DIN, or JIS) and insist on seeing the Material Test Report (MTR) for the exact batch of metal used for your parts. This is non-negotiable.

The Danger of Ambiguity

| Vague Request | Clear, Verifiable Request | The Outcome |

|---|---|---|

| "Brass Ball Valve" | "Valve Body: Forged Brass ASTM C377" | Prevents use of cheaper, less-resistant alloys. |

| "Stainless Steel Stem" | "Valve Stem: Stainless Steel SS316 (ASTM A276)" | Guarantees specific corrosion resistance for harsh media. |

| "Good quality seals" | "Seals: PTFE (Teflon), -50C to 200C" | Ensures compatibility with specific fluids and temperatures. |

How Can You Trust Quality from a Factory You've Never Seen?

Your potential supplier sends beautiful photos and promises top quality. But after you send the deposit, how do you know they aren't cutting corners on processes you can't see?

You can't rely on promises or photos. You must get a detailed Quality Plan in writing before you place the order. This should include their process for raw material verification, in-process inspection, and final testing.

This is the biggest fear for global buyers, and it's a valid one. This is where you separate a simple trader from a true manufacturing partner. A trader just places an order; a partner manages the quality. Before we even start a machine, we agree on a Quality Plan with the client. It’s a document that outlines every check-point. For instance: "Verify raw material with XRF spectrometer against MTR," "Check critical dimension #4 every 50 pieces and record data," and "Pressure test 100% of valves to 1.5x working pressure and provide test certificate." This is not an extra; it is a standard part of the process. For very large or critical orders, you can also hire a local third-party inspection agent to go to the factory on your behalf and verify an order before it ships. This small expense can save you a fortune.

The Transparent Partner vs. "Trust-Me" Supplier

| "Trust-Me" Supplier | Transparent Partner |

|---|---|

| Sends nice photos of the factory | Provides a written Quality Plan for your order |

| Says "Don't worry, quality is good" | Sends you actual in-process inspection reports |

| Gives vague excuses for problems | Documents every step and provides proof of final testing |

Is That Low Unit Price the Real Final Cost?

The unit price you were quoted from an overseas supplier is 40% lower than your local option. But you have a nagging feeling there are hidden costs you're not seeing.

Almost never. The unit price is just the beginning. You must calculate the Total Landed Cost, which includes shipping, insurance, import duties, and customs fees, to understand your true cost per part.

That low EXW (Ex-Works) price is designed to grab your attention. But an EXW price means you are responsible for everything once the parts leave the factory door. You have to arrange and pay for trucking in another country, ocean freight, insurance, port fees, customs brokerage, and import tariffs. These costs add up fast and can easily eat up your entire savings. To make an honest comparison, you need to calculate the Total Landed Cost. Work with a freight forwarder or customs broker to get estimates for these charges. You need to know the HS Code (Harmonized System Code) for your product to look up the import duty rate. Only when you add all these costs to the unit price and divide by the number of units do you know the real cost to get that part to your warehouse.

Calculating Your Total Landed Cost (Example)

| Cost Component | Description | Example Amount |

|---|---|---|

| Product Cost (EXW) | The price at the factory door for 1,000 units. | $5,000 |

| Freight/Shipping | Transport to your country (Ocean/Air). | $800 |

| Insurance | To protect against loss or damage in transit. | $50 |

| Import Duty | Tariff based on HS Code (e.g., 5%). | $250 |

| Brokerage/Port Fees | Fees for customs clearance and handling. | $300 |

| Total Landed Cost | The True Cost of Your Order | $6,400 |

| True Cost Per Unit | $6,400 / 1,000 units | $6.40 |

Conclusion

Global sourcing can be a powerful strategy. Success comes from managing details: master your specifications, demand verifiable quality, and calculate your total landed cost before committing. This builds reliable partnerships.