What is a Ball Valve and Why is It a Plumber's Go-To Choice?

You need to shut off the water, fast. But the old, round-handled valve is either frozen solid or spins without stopping the flow. You're facing a potential disaster.

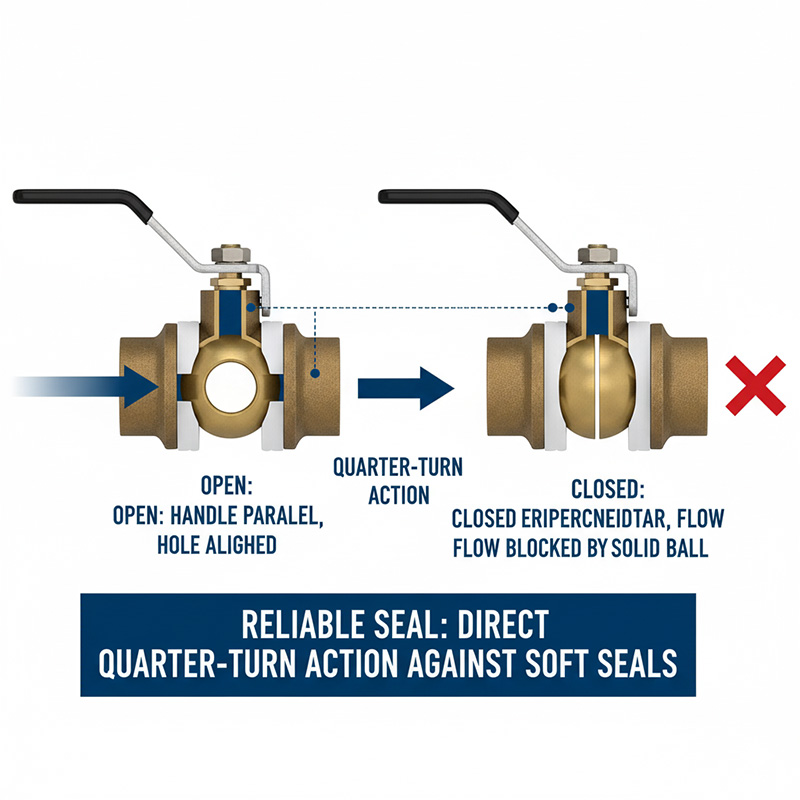

A ball valve is a shut-off valve that controls flow using a rotary ball with a hole in it. Plumbers prefer it because its quarter-turn handle provides a quick, clear, and highly reliable way to completely stop flow.

Jacky, your question takes me back to my first factory job. We had a huge injection mold with complex cooling lines running through it. The lines were controlled by old-style gate valves. One day, a seal failed, and we needed to shut off a specific line for repair. The valve handle just spun in place. We wasted an hour shutting down the entire system, all because of a cheap, worn-out valve. That day I learned that the simplest components are often the most critical. The ball valve is the perfect example of a simple, robust design that just works, and that’s a lesson every designer should appreciate.

How Does a Simple Quarter-Turn Provide Such a Reliable Seal?

You see a simple lever handle on a valve. How can a quick 90-degree flip be more effective than turning a round handle multiple times? It almost seems too easy.

The quarter-turn lever is directly connected to a perforated ball inside. When the handle is parallel to the pipe, the hole is open. When perpendicular, the solid part of the ball blocks the flow completely against soft seals.

The beauty of the ball valve is its simplicity, which is the heart of all great engineering design. Inside the valve body, there are really only a few key parts.

The Core Components

- The Ball: A sphere with a hole, or "bore," drilled straight through it.

- The Seats: Two soft, durable rings (often made of Teflon/PTFE) that the ball nests between.

- The Stem: The shaft that connects the external handle to the ball.

- The Body: The outer casing that holds everything together.

When you turn the handle, the stem rotates the ball. In the open position, the bore is aligned with the pipe, allowing unrestricted flow. This is a key advantage called "full-port" or "full-bore" design. When you turn the handle 90 degrees, the solid side of the ball rotates to press against the seats. The water pressure helps push the ball firmly into the downstream seat, creating an incredibly tight seal. This positive shutoff is far more reliable than the metal-on-metal closure of older valve designs.

What Makes a Ball Valve More Reliable Than an Old Gate Valve?

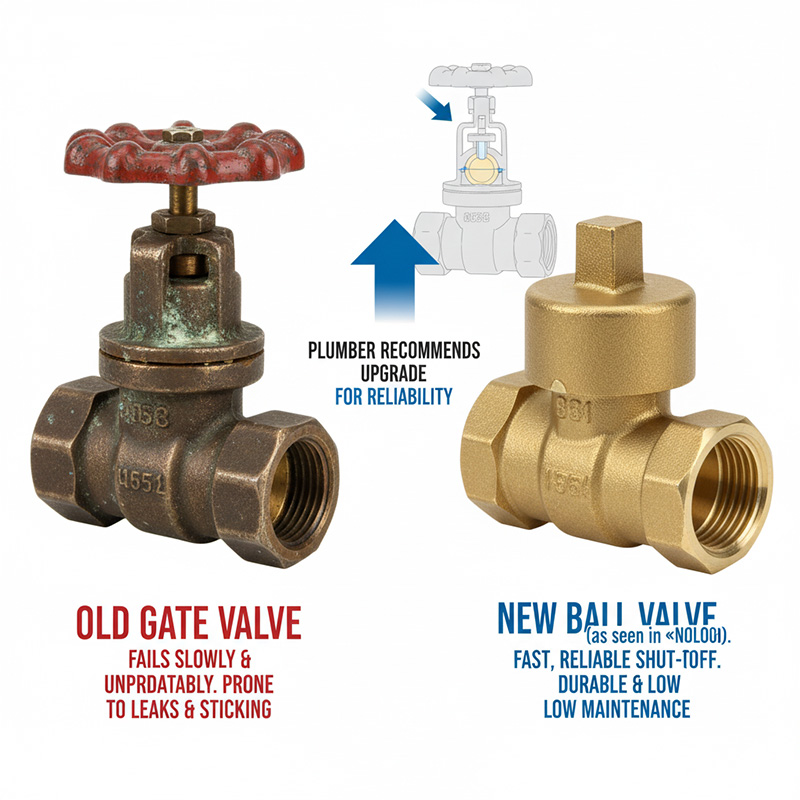

You have an old gate valve that has worked for years. Why would a plumber insist on replacing it with a ball valve during a renovation? It seems like an unnecessary change.

Gate valves fail slowly and unpredictably. Their screw mechanism wears out, and mineral deposits can prevent them from closing fully. A ball valve's simple, wiping action and tight seal make it far more durable and trustworthy.

This is a classic case of superior design replacing outdated technology. I saw this in manufacturing when high-speed steel was replaced by carbide for cutting tools. The performance difference was so significant that the old way quickly became obsolete. The ball valve versus the gate valve is the exact same story in the world of plumbing. A gate valve works by lowering a metal "gate" to block the flow. It sounds good in theory, but in practice, it has several major flaws that the ball valve solves.

| Feature | Ball Valve | Gate Valve |

|---|---|---|

| Speed of Operation | Instant: Quarter-turn (90°) for on/off. | Slow: Requires multiple 360° turns to open or close. |

| Sealing Reliability | Excellent: Ball presses on soft seats for a tight seal. | Poor to Fair: Metal gate seats can wear, corrode, or trap debris. |

| Visual Confirmation | Clear: Handle position shows if it's open or closed. | Unclear: No easy visual indicator of the valve's state. |

| Durability | High: Simple mechanism with few moving parts. | Low: Screw stem and seat can wear out, threads can strip. |

| Common Failure Mode | Rare, but can fail if used for throttling. | Stem breaks, valve gets stuck open/closed, or leaks when closed. |

Are There Situations Where a Ball Valve Isn't the Best Choice?

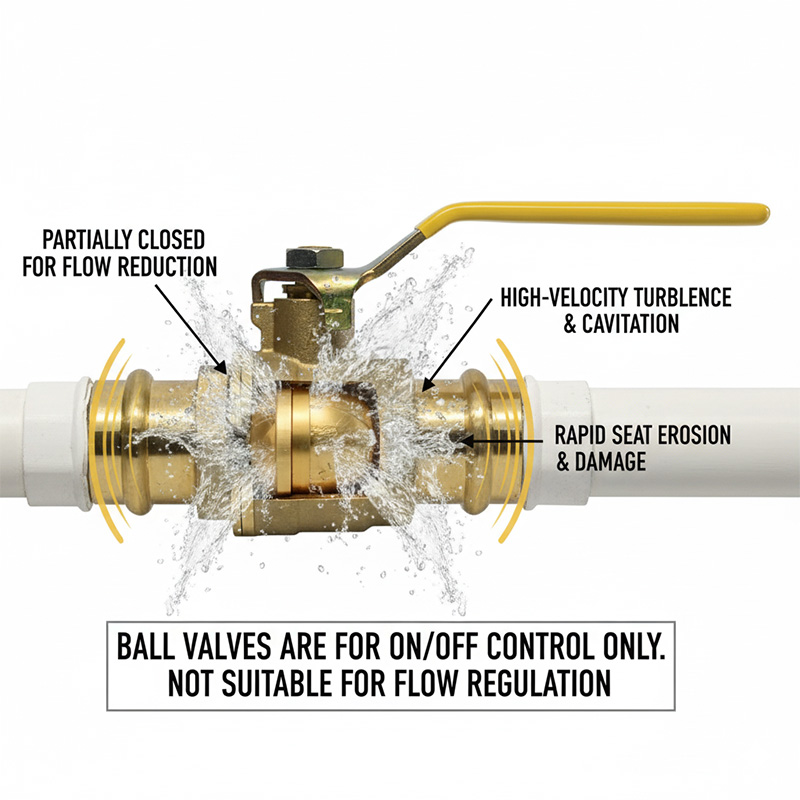

You need to reduce, not stop, the flow of water to an appliance. You try partially closing a ball valve, but it makes a loud hissing noise and vibrates.

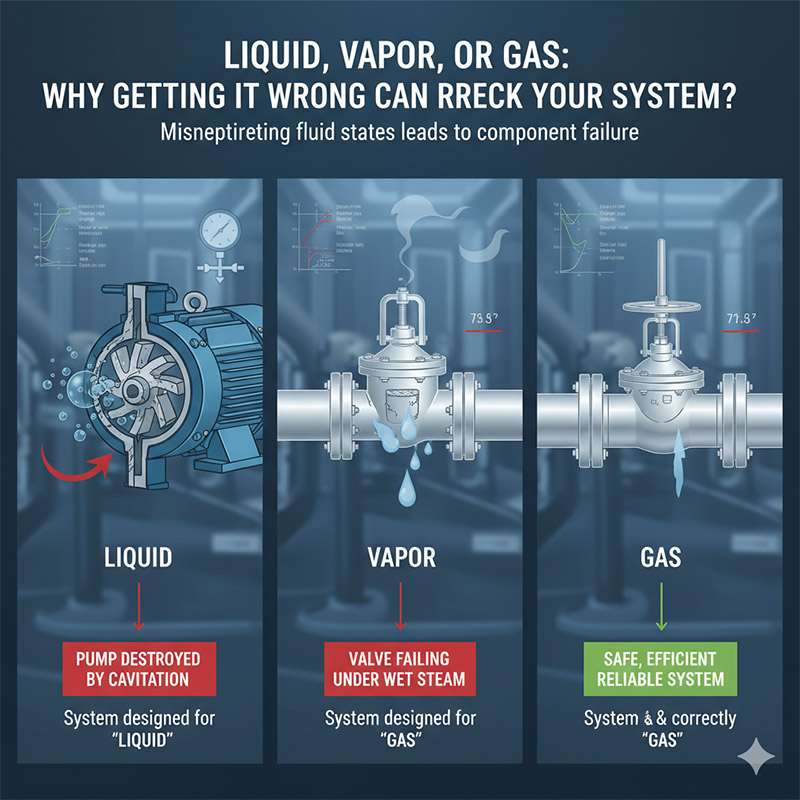

Yes, ball valves are designed for on/off control only, not for regulating flow. Partially opening a ball valve creates high-velocity turbulence that can quickly erode the internal seats and ball, causing the valve to fail.

Using the wrong tool for the job is a mistake we all make, but in mechanics and fluid dynamics, it can lead to rapid failure. A ball valve is a perfect switch, but a terrible dimmer.

The Problem with Throttling

When you partially open a ball valve, the small opening an the sharp edge of the ball's bore creates a jet of high-velocity water. This effect, often called cavitation or wire drawing, is like sandblasting the inside of the valve. The soft PTFE seats get chewed away, and the surface of the ball itself can become pitted. Before long, the valve will no longer be able to create a tight seal, even when fully closed. You will have destroyed the very feature that makes it so valuable.

The Right Tool for Throttling

For applications where you need to precisely control the amount of flow, the best choice is a globe valve or a needle valve. A globe valve has a plug that lowers into a matching seat, offering much finer control over flow volume. A needle valve is even more precise, using a long, tapered needle-like plunger, perfect for low-flow and fine-adjustment applications.

Conclusion

A ball valve provides simple, reliable on/off control. Its quarter-turn operation and robust design are why plumbers trust it for quick, leak-proof shutoffs, making it a cornerstone of modern plumbing systems.