What Is a Sight Glass? Simple Explanations to Make Pipe Checks Way Easier?

You're operating in the dark. Your pipes and tanks are black boxes, and you're just hoping everything inside is flowing as it should. This guesswork creates constant, low-level anxiety.

A sight glass is your window into the machine. It’s a simple, tough viewport installed directly in your system that lets you see the fluid's flow, color, and condition instantly, turning uncertainty into confident control.

It's funny, Jacky, this takes me back to my early days on the factory floor. We'd have issues with a mold's cooling channels getting clogged. We couldn't see inside the steel block, so we'd have to guess. We'd waste hours trying to diagnose a problem that a simple window could have revealed in seconds. A sight glass provides that simple, undeniable truth. It’s the most basic and powerful diagnostic tool you can add to a fluid system. It’s about making the invisible, visible.

The Unseen Cost: How Guesswork in Your Pipes Wastes Money and Risks Safety?

Flying blind with your system feels manageable, until it isn't. This uncertainty leads to sudden downtime, expensive emergency repairs, and even serious safety hazards from undetected problems.

Guesswork directly hits your bottom line. It delays diagnosis, allowing minor issues like a clogged filter to cause major equipment damage. This creates expensive, unscheduled downtime and introduces safety risks from potential leaks or pressure buildups.

In the CNC business, unplanned downtime is the ultimate enemy. A machine that isn't running isn't making money. The costs of guesswork aren't just about the parts you have to replace; they multiply quickly. I've seen a simple coolant blockage, something a sight glass would spot instantly, lead to a broken tool, a scrapped part worth thousands, and a day of lost production. Let's break down these hidden costs:

| Cost Type | Example | Impact |

|---|---|---|

| Direct Costs | Replacing a pump that burned out from running dry. | High repair bills, replacement parts. |

| Indirect Costs | Lost production time while a machine is down for repair. | Missed deadlines, damaged reputation. |

| Safety Costs | A sudden release of hot or pressurized fluid from a failed component. | Risk of injury, cleanup expenses. |

These costs are not theoretical. They happen every day in facilities that rely on hoping for the best instead of confirming with a simple visual check.

More Than a Window: What Is a Sight Glass and Why Is It a Mechanical Essential?

You might look at a sight glass and see a simple fitting—a piece of glass in a metal frame. It seems basic, maybe even an optional extra for your system.

But it’s an engineered safety component. A sight glass is a miniature pressure vessel, designed to provide safe observation under demanding conditions. It's essential because it delivers immediate, real-time data about your system's health without complex sensors.

Think about the difference between a window in your house and the window on an airplane, Jacky. They both let you see outside, but one is designed to withstand a massive pressure difference and extreme temperatures. A sight glass is like that airplane window. It’s not just a piece of glass; it’s a fully engineered system. The thickness of the glass, the material of the body, and the type of seal are all carefully chosen to handle the specific pressures and temperatures of the process. It provides the most reliable form of data—direct visual evidence—without needing calibration, power, or software. In a world of complex sensors, the sight glass remains an essential tool because of its pure simplicity and reliability.

The Nuts and Bolts: How a Basic Sight Glass Brings Clarity to Complex Systems?

Your system has dozens of sensors, but you still can't pinpoint a simple blockage. You're drowning in data but starved for simple answers. A more fundamental tool is needed.

A sight glass works through direct observation, made possible by three core components: a robust metal body for strength, a pressure-rated transparent window, and high-integrity seals to prevent leaks. This simple, strong assembly creates a secure viewport.

When you get down to it, the reliability of any mechanical design is in its components. As a designer, Jacky, you know this better than anyone. A sight glass is a perfect example of a few simple parts working together perfectly to perform a critical function.

- The Body (Frame): This is the backbone. It’s typically cast or forged from materials like ductile iron, carbon steel, or stainless steel. The body provides the connection points (threaded or flanged) and contains the pressure of the entire assembly.

- The Window (Glass): This is the heart of the device. It’s never ordinary glass. It is always toughened, or "tempered," glass to handle pressure and sudden temperature changes. For more extreme applications, borosilicate or quartz glass is used for superior thermal shock resistance.

- The Seals (Gaskets): These are the unsung heroes. Positioned between the glass and the body, these gaskets create the pressure-tight seal. The material is critical and must be chosen for compatibility with the fluid, from standard neoprene to specialized Teflon for aggressive chemicals.

A failure in any one of these parts means a failure of the entire unit. It’s just like in mold design—even the smallest O-ring failing can bring a million-dollar machine to a halt.

Where Sight Glasses Shine: Critical Applications from Chemical Tanks to Heavy Machinery?

You can't just open a hatch on a running chemical reactor or a pressurized hydraulic tank. You need a safe, non-invasive way to see what's going on inside.

Sight glasses are essential in any application where you need to verify fluid level, flow, or condition safely. They are critical for tanks, pipelines, gearboxes, and steam systems, providing an immediate visual check in potentially hazardous environments.

This is where the theory meets the real world. On the factory floor, these aren't just components; they are problem-solvers. Here are a few places where a sight glass is non-negotiable:

Level Monitoring in Vessels

On a large hydraulic oil reservoir for a stamping press, a sight glass on the side instantly tells you the fluid level. It’s faster and more reliable than a dipstick and safer than opening a fill cap on a running machine.

Flow Verification in Pipelines

We used them on the coolant return lines of our big CNC mills. A quick glance at a sight glass with a built-in spinner or "flipper" instantly confirmed we had positive coolant flow to a multi-million dollar machine, preventing tool burnout.

Condition Monitoring in Gearboxes

The oil in a massive industrial gearbox is its lifeblood. A sight glass at the drain port allows maintenance crews to check for discoloration or water contamination (the oil will look milky) without having to take a sample, flagging a problem before a catastrophic gear failure.

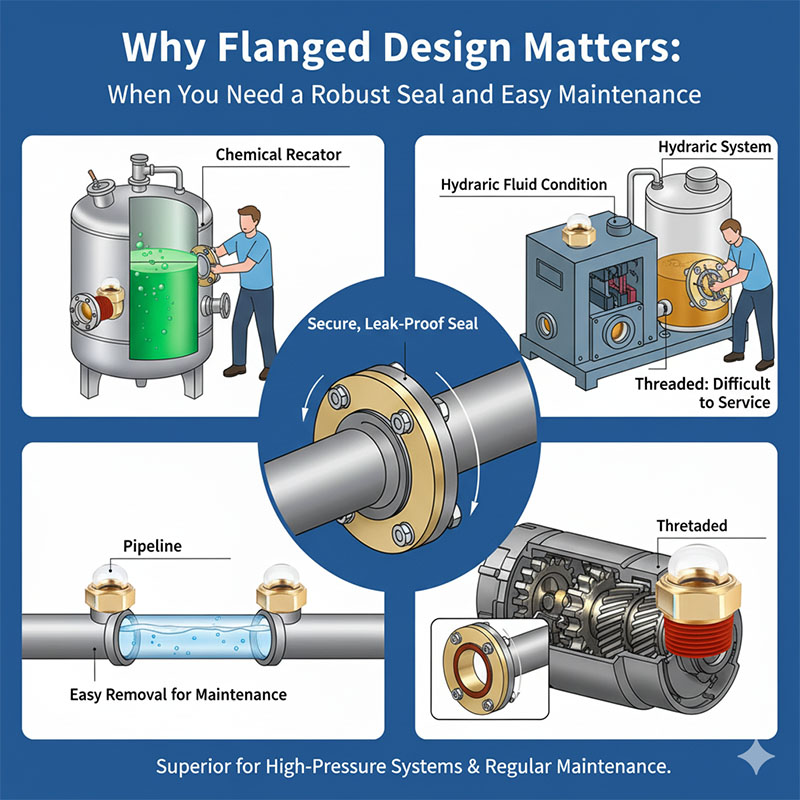

Why Flanged Design Matters: When You Need a Robust Seal and Easy Maintenance?

Threaded pipe fittings are fine for simple jobs, but they can be difficult to service. In larger, high-pressure systems, you always worry about the integrity of a threaded seal.

A flanged sight glass is superior for high-pressure systems and lines requiring regular maintenance. The bolts provide a secure, evenly distributed clamping force for a leak-proof seal, and the entire unit can be easily removed and replaced.

This is a classic mechanical design choice, Jacky. It’s about choosing the right tool for the job. We faced the same decision in mold making. Simple prototype molds might be held together with a few screws. But a high-volume production mold that withstands tons of injection pressure is held together with massive clamps and numerous heavy-duty bolts. The principle is identical. A flanged connection distributes the clamping force evenly around the seal, creating a more reliable and robust connection.

| Feature | Threaded Connection | Flanged Connection |

|---|---|---|

| Sealing | Depends on the integrity of the threads and sealant. Prone to leaking if damaged. | Relies on even gasket compression between two flat faces. Very reliable. |

| Pressure | Best for smaller diameters and lower-pressure systems. | The standard for larger, high-pressure, and high-temperature service. |

| Maintenance | Difficult. You often have to cut the pipe or disassemble a large section. | Simple. Just unbolt the flanges to remove the sight glass for cleaning. |

For any critical or large-scale application, the safety and serviceability of a flanged design make it the clear professional choice.

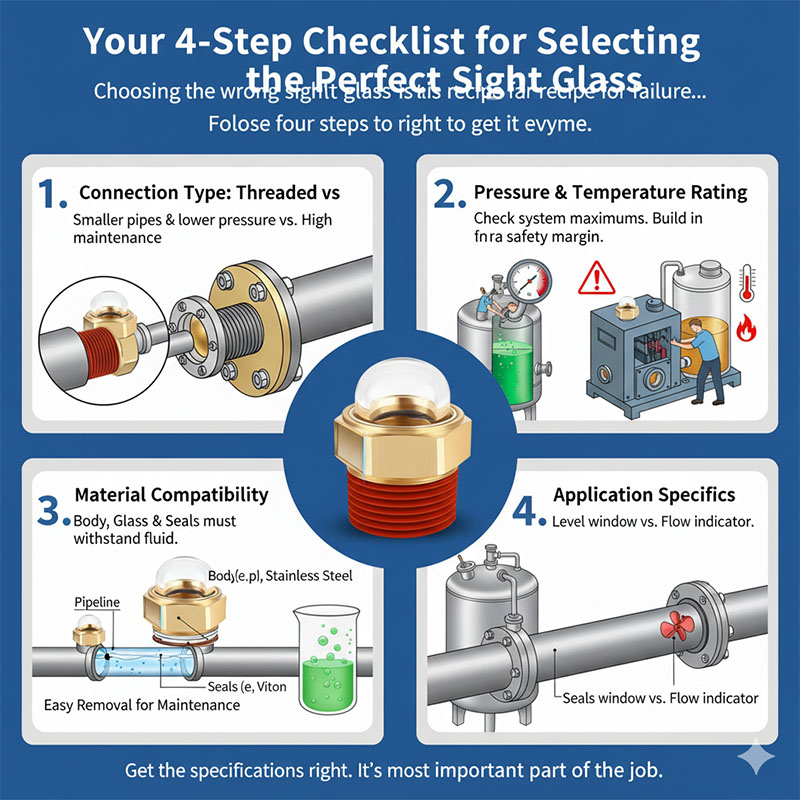

Your 4-Step Checklist for Selecting the Perfect Sight Glass?

Choosing the wrong sight glass is a recipe for failure. A component that can't handle the pressure, temperature, or chemicals in your system is not a bargain; it's a liability.

To select the right sight glass, use this 4-step checklist: confirm the connection type, verify the pressure and temperature ratings, ensure material compatibility, and consider any application-specific features you may need.

Conclusion

A sight glass is a small investment for a huge return in safety, efficiency, and control. It brings essential clarity, stopping dangerous guesswork and empowering proactive maintenance in any system.