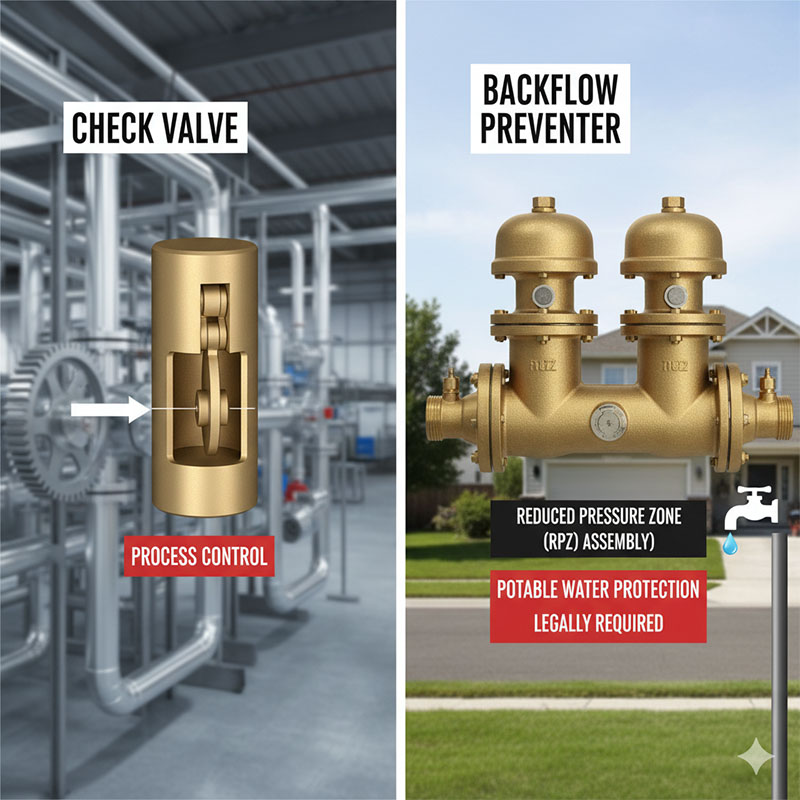

Are a Check Valve and a Backflow Preventer Actually the Same Thing?

You hear the terms "check valve" and "backflow preventer" used on the factory floor, sometimes interchangeably. But you know there's a critical, and potentially costly, difference between them.

No, they are not the same. A check valve is a simple, one-way valve for process control inside a machine. A backflow preventer is a complex, failsafe system designed to protect potable water supplies from contamination, and is often legally required.

I'll never forget a consultation I did for a large plastics facility. They had just installed a massive new cooling tower system. The city inspector came for a final sign-off and immediately failed them. The problem? The plumbing contractor had installed a heavy-duty check valve on the main water line feeding the tower. The contractor argued, "It stops backflow, what's the problem?" The inspector's reply was simple and firm: "That valve isn't testable, it isn't failsafe, and it doesn't protect against back-siphonage. It's a component, not a safety system." They had to tear it out and install a proper Reduced Pressure Zone (RPZ) backflow preventer, which cost them tens of thousands in parts, labor, and production delays. That day taught me that understanding this difference isn't just academic; it's about safety, compliance, and money.

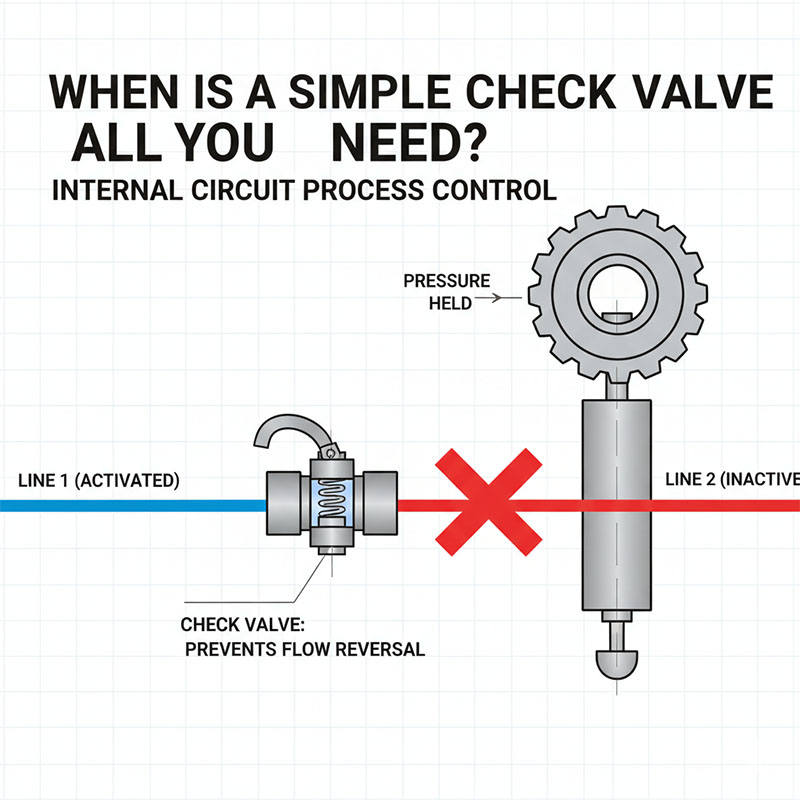

So, When Is a Simple Check Valve All You Need?

You're designing a hydraulic circuit and need to make sure pressure holds in one line when another is activated. A big, expensive backflow preventer seems like massive overkill.

You're right, it is. This is the perfect job for a check valve. These simple devices are the workhorses of internal circuits, designed to direct traffic and prevent flow reversal during normal operation.

A check valve is the ideal component for managing flow direction within a contained system. Its purpose is process control, like preventing a hydraulic cylinder from drifting or ensuring cooling water flows in the intended loop, not protecting public health.

As a mold designer, I use check valves all the time. Think about a mold with a hydraulic core pull sequence. You extend the first cylinder, and you need it to stay put while the second one moves. A simple check valve placed in the hydraulic line after the first cylinder does exactly that. It lets the oil in but won't let it back out until you apply pressure to the retract side. It’s a simple, reliable, and cost-effective way to manage the internal functions of a machine. Using a complex backflow preventer here would be like using a sledgehammer to hang a picture frame—it’s the wrong tool, it's too expensive, and it creates unnecessary complexity. Check valves are the unsung heroes of process reliability.

Common Types of Check Valves

They come in various simple designs, each with its own pros and cons for different applications within a mold or hydraulic power unit. The key is that they are all passive devices.

| Valve Type | How It Works | Common Use Case |

|---|---|---|

| Spring-Loaded Ball/Poppet | A spring holds a ball or poppet against a seat. Flow pressure pushes it open. | Hydraulic lines; works in any orientation. |

| Swing Check | A hinged disc (flapper) swings open with flow and swings shut with gravity or reverse flow. | Water lines; often requires horizontal installation. |

| Diaphragm Check | A flexible rubber diaphragm flexes open with flow and lays flat to seal against reverse flow. | Low pressure or applications with small debris. |

Why Do Backflow Preventers Seem So Complicated and Expensive?

Your facility's main water line requires a bulky, multi-ported device that costs a fortune. Why can't you just use a high-quality check valve and call it a day?

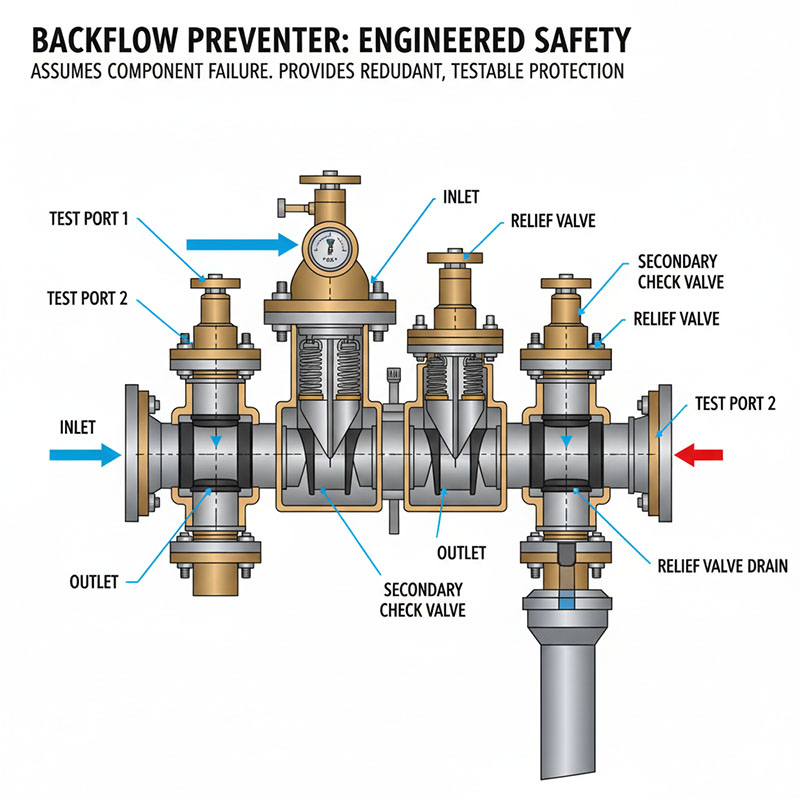

That complexity is your guarantee of safety. A backflow preventer is an engineered safety system that assumes its own components will fail. Its design provides redundant, testable protection to absolutely ensure contaminated water never enters the clean supply.

A backflow preventer is required by law when connecting any industrial process to a public or private potable water supply. Its job is to create a physical barrier to contamination that is both failsafe and verifiable through regular testing.

The reason for the complexity is that these devices must protect against two distinct dangers: back-pressure and back-siphonage. Back-pressure happens when your equipment (like a pump) creates a higher pressure than the city supply, trying to push water backward. Back-siphonage happens when the city supply loses pressure (like from a water main break), creating a vacuum that tries to suck water out of your facility. A simple check valve might handle one of these, but it can't handle both reliably. A Reduced Pressure Zone (RPZ) backflow preventer uses two independent check valves and a relief port in the middle. If even a small leak occurs in the second check valve, the relief port opens and dumps the "captured" water to the floor. It physically cannot fail in an unsafe way. This is why they have test ports—to prove this system is working.

Check Valve vs. Backflow Preventer: The Key Differences

| Feature | Check Valve | Backflow Preventer (RPZ Type) |

|---|---|---|

| Purpose | Process Control | Public Health & Safety |

| Design | Single valve component | Engineered system with multiple valves & vents |

| Failure Mode | Can fail stuck open, allowing backflow | Fails by dumping water, preventing contamination |

| Testability | Not designed for in-line testing | Has test ports for mandatory regular inspection |

| Application | Inside a machine (hydraulics, cooling loops) | At the connection to a potable water supply |

Conclusion

Use a check valve for process control inside your mold or machine. Use a backflow preventer to protect drinking water at the main supply. Knowing this difference is key to safe, compliant design.