Why Does Choosing the Right Valve and Fitting Supplier Matter More Than You Think?

A cheap fitting just failed, halting your entire line. Now you're scrambling, facing costly delays and tough questions from management about your sourcing decision.

Choosing the right supplier is more than a transaction; it's a strategic partnership. It mitigates risks related to quality, downtime, and supply chain stability, directly protecting your project's budget and timeline.

I once got a frantic call from a client who manufactures high-end commercial coffee machines. Their assembly line was completely stopped. A batch of brass elbow fittings from a new, low-cost supplier had microscopic cracks, causing them to fail the final pressure test. They had thousands of these defective parts. The initial savings of about fifty cents per part ended up costing them tens of thousands in lost production and rework. That day, my client didn't just need a new fitting; they needed a reliable partner. This is a story I've seen play out in different ways across the industry. Your supplier isn't just sending you a box of parts. Their quality, expertise, and reliability become woven into your own product and your reputation. Choosing wisely is one of the most powerful decisions you can make.

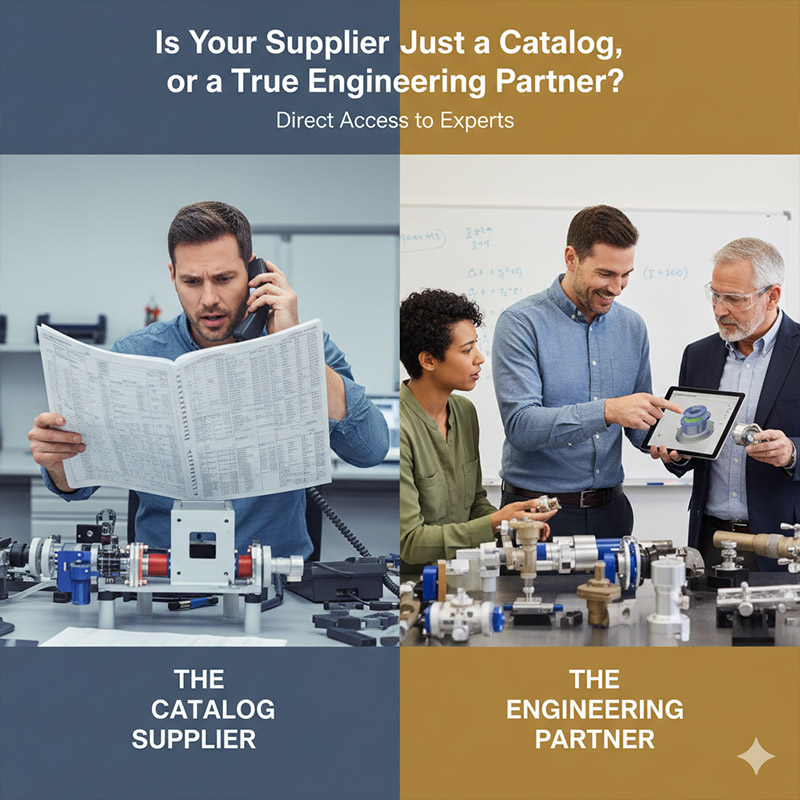

Is Your Supplier Just a Catalog, or a True Engineering Partner?

You need a valve for a unique application, but your supplier contact can only read you a part number. You're left guessing, risking a costly and embarrassing design failure.

A true partner moves beyond the catalog. They provide direct access to engineers who can discuss material compatibility, pressure ratings, and even suggest custom modifications to solve your specific problem.

In my experience, the best suppliers are the ones who start by asking "why." Why this pressure? Why this temperature? What fluid is running through it? They want to understand your project. This is a massive clue that you're talking to a partner, not just a reseller. For a designer like you, Jacky, this is invaluable. It’s like having an extension of your own engineering team. A salesperson is trained to sell what's on the shelf. An engineering partner is trained to help you succeed, even if it means creating something new. This collaborative approach leads to better, more reliable end products because they are designed for their real-world application from the very beginning.

Beyond the Part Number

The first conversation tells you everything. A reseller asks for a part number and quantity. A partner asks about your project's challenges. They will bring up potential issues you may not have even considered, such as seal material degradation with certain chemicals or the effects of water hammer in your system.

The Power of Customization

Your project may not fit a standard, off-the-shelf part. A true partner has the engineering depth and manufacturing flexibility to offer modifications. This could be as simple as a different thread type or as complex as developing a valve with a specific flow rate. This capability turns them from a simple supplier into a powerful problem-solving resource.

| Aspect | Sales Clerk | Engineering Partner |

|---|---|---|

| Primary Goal | Move inventory | Solve your technical problem |

| First Question | "What's the part number?" | "Tell me about your application." |

| Customization | "Not in the catalog." | "Let's discuss the modifications." |

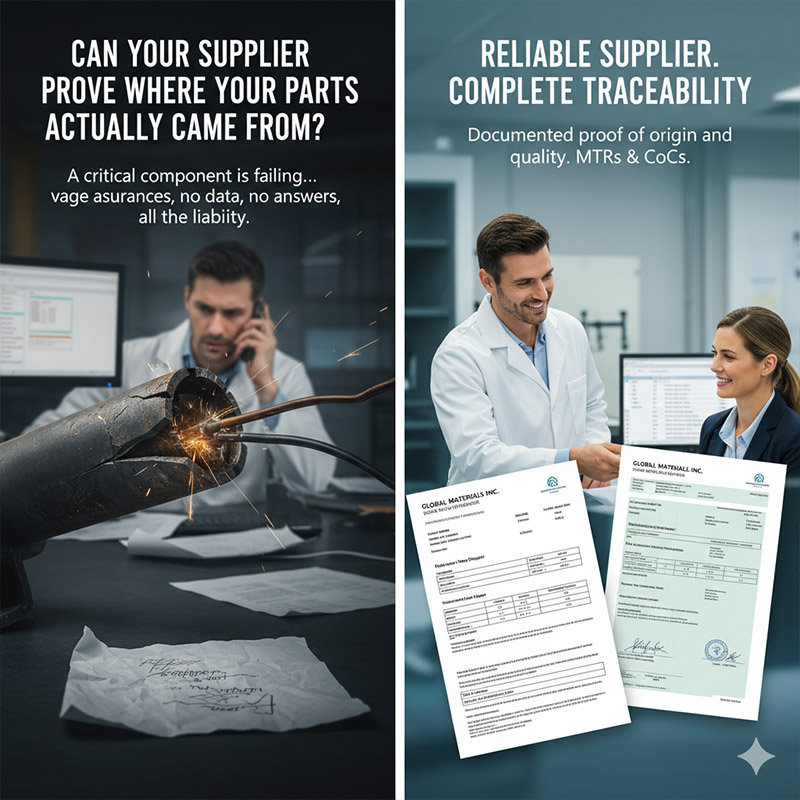

Can Your Supplier Prove Where Your Parts Actually Came From?

A critical component is failing in the field, and you suspect a material issue. Your supplier gives you vague assurances, leaving you with no data, no answers, and all the liability.

A reliable supplier provides complete material traceability through documentation. This includes Material Test Reports (MTRs) and Certificates of Conformance (CoC), giving you documented proof of the material's origin and quality.

"Trust me, it's good quality." These are some of the most expensive words in manufacturing. In today's global supply chain, you have to verify. A reputable supplier is never afraid to show their work. They understand that for industrial applications, the material isn't just a suggestion; it's a specification. The difference between 304 and 316 stainless steel, or between C360 and C464 brass, can be the difference between a product that lasts for decades and one that fails in months. Requesting documentation isn't being difficult; it's being professional. A supplier who readily provides this paper trail is a supplier who has confidence in their process and respects the importance of your work. It's a clear sign that they manage their supply chain responsibly.

The Paper Trail is Your Protection

- Material Test Report (MTR): This document from the metal mill certifies the exact chemical composition and physical properties of the raw material. It's your proof that the brass or steel is exactly what it claims to be.

- Certificate of Conformance (CoC): This document from the manufacturer states that the parts they produced for your specific order meet all of your drawing specifications and quality requirements.

| Level of Assurance | Vague Supplier | Traceable Partner |

|---|---|---|

| Material Proof | Verbal promise | Provides Material Test Report (MTR) |

| Quality Proof | "It passed our QC." | Provides Certificate of Conformance (CoC) |

| Your Risk Level | High | Low |

Does Your Supplier's Problem Immediately Become Your Crisis?

Your production is scheduled to the day, but you just got a surprise email: your critical fittings are delayed by three weeks. Now your entire project schedule is in jeopardy.

A true partner sees your supply chain as their responsibility. They manage safety stock, offer transparent lead times, and communicate proactively about any potential disruptions, allowing you to plan instead of panic.

A low price is meaningless if the part isn't there when you need it. In my years running a trading company, I learned that supply chain reliability is just as important as product quality. A weak supplier is reactive. They tell you about a problem after it has already become your crisis. A strong partner is proactive. They have a deep understanding of their own supply chain, from raw material sourcing to shipping logistics. They carry safety stock of critical materials to buffer against market volatility. Most importantly, they communicate honestly and early. A partner who calls you to say, "There might be a shipping delay in three weeks, let's look at our options," is infinitely more valuable than one who apologizes after the delivery is already late.

Transparency Builds Trust

A good partner will let you know where your order is in their production queue. They won't hide behind vague answers. This transparency allows you to manage your own production schedules with confidence.

The Value of a Stable Operation

Look for suppliers with a stable history and control over their processes. A vertically integrated manufacturer who performs more steps in-house often has much better control over lead times and quality than a company that simply outsources everything. This stability is your best defense against surprise delays.

| Supply Chain Trait | Reactive Supplier | Proactive Partner |

|---|---|---|

| Communication | Apologizes for delays | Warns about potential issues |

| Inventory | Orders just-in-time | Holds strategic safety stock |

| Lead Times | Unpredictable | Stable and transparent |

Conclusion

Choosing a supplier isn't just about the part. It's an investment in a partnership that guarantees quality, solves problems, and secures the success of your entire project.