How Does a Pipe Bang Stopper Tame Violent Water Hammer?

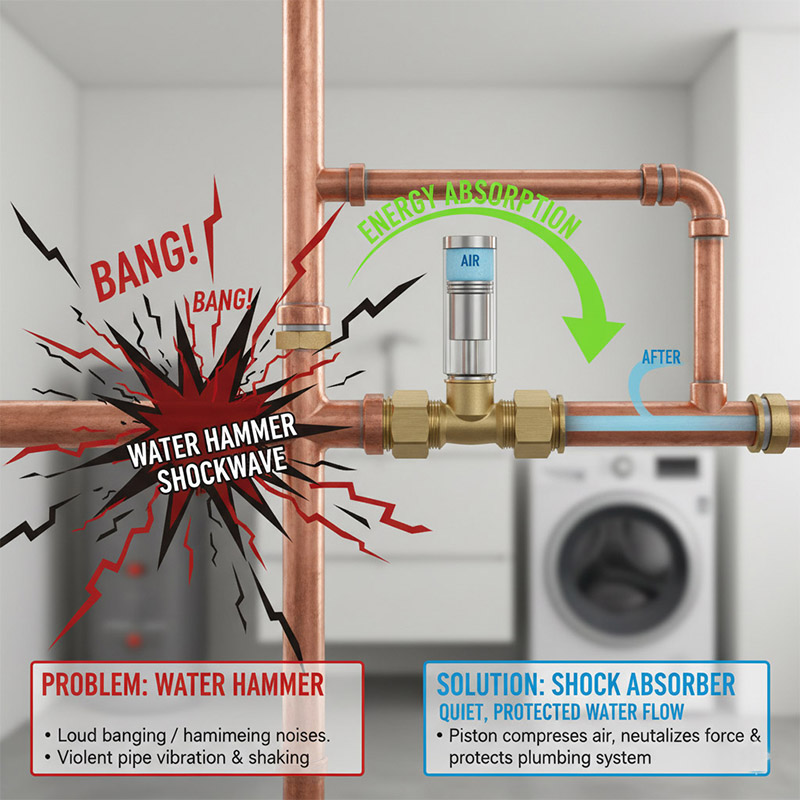

Hear loud, shocking bangs from your walls when a faucet shuts off? This is water hammer, a destructive force that can damage pipes and cause expensive leaks.

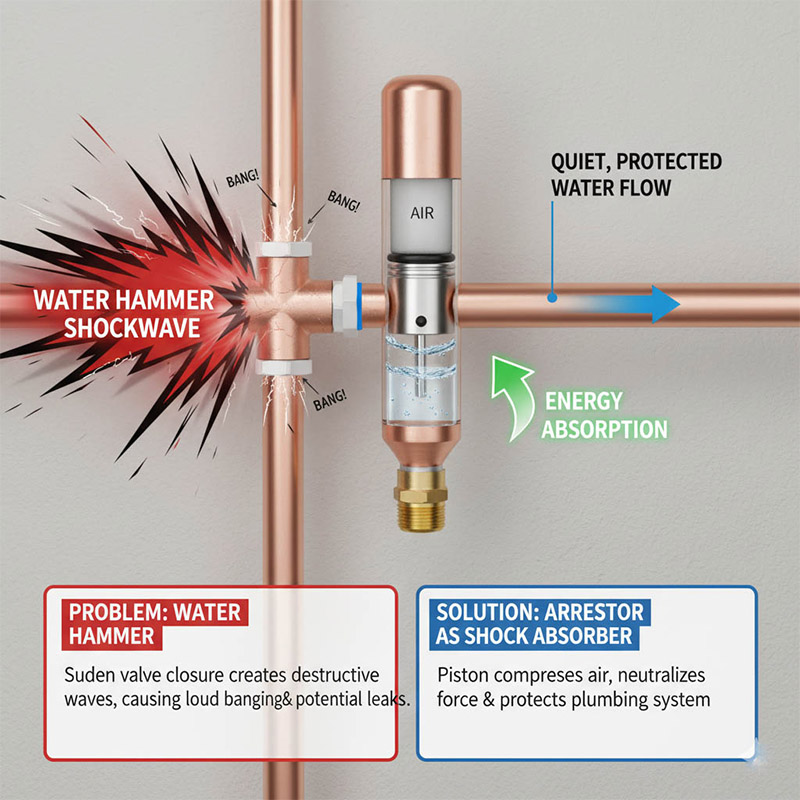

A water hammer arrestor acts as a shock absorber for your plumbing. It's a small chamber with a piston or diaphragm separating water from a cushion of air. When a valve closes suddenly, this device absorbs the resulting pressure wave, safely neutralizing the damaging force and stopping the noise.

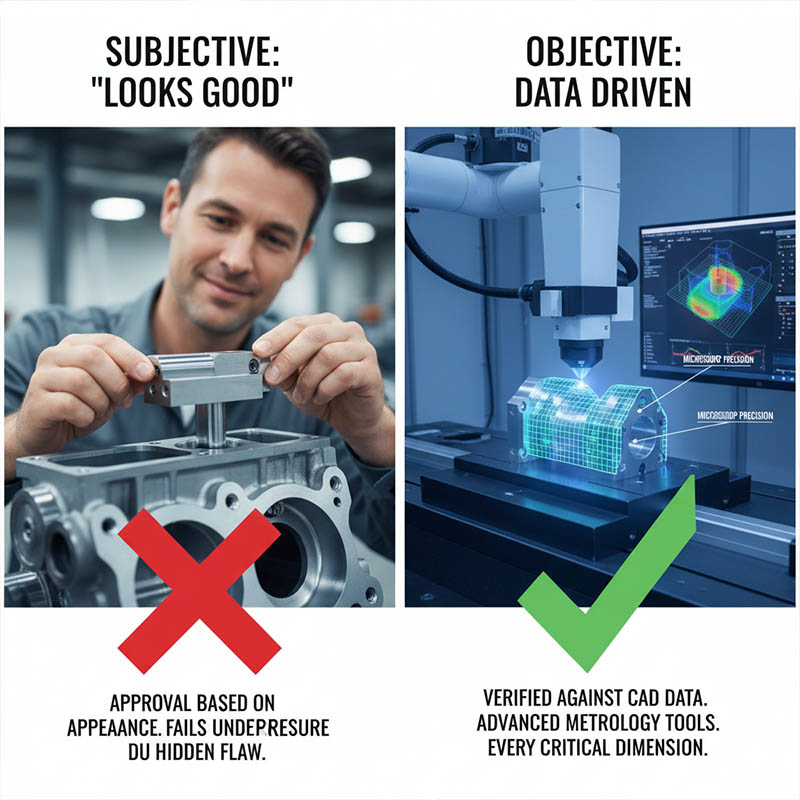

This device is a beautiful example of engineered energy dissipation. It reminds me of designing hydraulic systems for large injection molds. Without an accumulator to absorb pressure spikes when a valve closed, the hydraulic lines would jump and chatter, eventually leading to fatigue failure. The water hammer arrestor is simply a miniature, purpose-built accumulator for your plumbing. As a designer, Jacky, you'd appreciate its elegant simplicity; it’s a pure mechanical solution to a pure mechanical problem, protecting the entire system with one small, clever component.

What is water hammer, and what are the signs?

Startled by a loud bang from your walls after a wash cycle finishes? This sudden, alarming noise is a sign that unseen forces are stressing your entire plumbing system. Water hammer is a hydraulic shockwave created when a fast-flowing liquid is forced to stop or change direction suddenly. The primary signs are a loud banging or series of hammering noises from pipes, often accompanied by noticeable vibration of the pipes themselves.

The physics behind this is quite powerful. Imagine a long freight train moving at speed, and the engine suddenly hits an immovable wall. The energy of all the connected cars has to go somewhere, causing them to slam into each other. Water in a pipe has mass and momentum, just like that train. When a fast-acting valve (like a dishwasher's or washing machine's solenoid valve) closes instantly, the moving column of water crashes to a halt. This creates a high-pressure shockwave that travels back up the pipe at the speed of sound. As a product designer, Jacky, you understand forces and material limits. This pressure spike can be many times the normal operating pressure, stressing joints, fittings, and the pipes themselves, leading to eventual failure. It's a classic case of kinetic energy being converted into destructive pressure.

Common Signs and Their Meanings

| Sign | What It Indicates | Severity Level |

|---|---|---|

| Loud Banging/Hammering | A significant pressure wave is being created. | High |

| Vibrating or Shuddering Pipes | The shockwave is physically moving the pipes. | Medium to High |

| Faint Clicking or Ticking | Could be a minor water hammer or pipes expanding/contracting. | Low |

| Leaking at Fittings/Joints | The pressure spikes may have already caused damage. | Critical |

What does a water hammer arrestor do?

Hear your pipes bang and wonder what you can actually do about it? Ignoring the problem allows the hidden damage to continue, risking a sudden and catastrophic pipe failure.

A water hammer arrestor absorbs the energy of the hydraulic shockwave. Its internal piston or diaphragm compresses a sealed cushion of air or gas, smoothly dissipating the pressure spike before it can travel through the plumbing system and cause banging noises or damage.

The design is brilliantly simple and effective. It provides an engineered weak point for the pressure to escape into. Without an arrestor, the shockwave's energy is absorbed by the pipe walls, joints, and fixtures, which are rigid and not designed for that kind of impact. An arrestor introduces an element of compressibility into an otherwise incompressible system. In my mold manufacturing business, we had to be very careful with water cooling channels. A sudden pressure spike could crack a multi-ton block of steel. We used pressure relief valves, but an arrestor works on a similar principle of providing a safe outlet for unexpected energy. For a designer like you, Jacky, the beauty is in its passive operation. It uses the problem's own energy to solve itself, requiring no external power or control. It just sits there, ready to absorb the impact.

Do I need a plumber for water hammer?

Worried that fixing a banging pipe requires a costly professional visit? The thought of calling a plumber for just a noise can feel like an overreaction, but ignoring it feels risky.

For installing new arrestors that require cutting into pipes, a plumber is highly recommended. However, for simple screw-on types at a specific appliance (like a washing machine), it can be a straightforward DIY job. A plumber is essential for diagnosing complex cases.

Think of it as a tiered solution, a concept we use in product development all the time. Tier 1 is the simple, user-installable fix. This is your screw-on arrestor that attaches directly to a hose bib. It requires no special tools beyond a wrench. Tier 2 is more involved. If the problem is system-wide, you might need arrestors installed on the main lines near the source, which often requires a plumber to cut, solder, or crimp the new fittings into place. Tier 3 is diagnosis. If you install arrestors and the banging persists, a plumber is needed to investigate other potential causes, like improper pipe strapping or water pressure that's too high. For you, Jacky, the screw-on type is a well-designed "consumer" product, while the in-line type is a "professional" component requiring skilled installation. Knowing which one you need is the first step.

When to Call a Plumber

| Scenario | DIY Feasible? | Plumber Recommended? | Rationale |

|---|---|---|---|

| Installing Screw-On Arrestor on a Hose | Yes, typically | No | A basic threaded connection, like attaching a garden hose. |

| Banging is Wide-Spread (Multiple Fixtures) | No | Yes | Problem may require multiple arrestors or pressure regulator. |

| Installing In-Line (Solder/Crimp) Arrestor | No, unless experienced | Yes | Requires specialized tools and skills to avoid leaks. |

| Arrestors are Installed but Banging Continues | No | Yes | A deeper issue exists that requires expert diagnosis. |

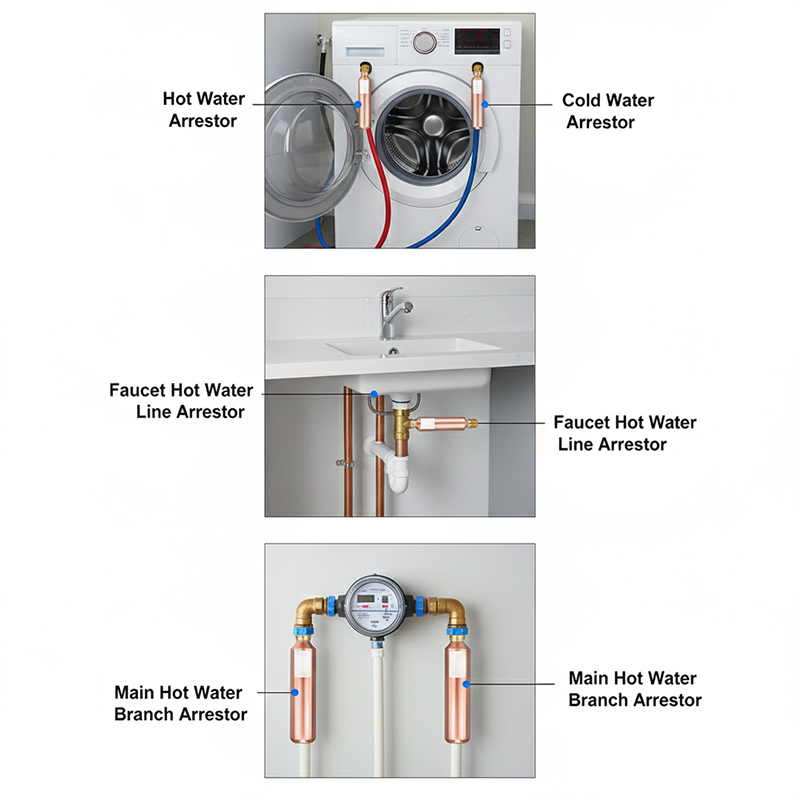

Where should you install a water hammer arrestor, and how many do you need?

Bought an arrestor but now you're not sure where it goes? Placing it in the wrong spot can make it completely ineffective, wasting your time and money.

Install the arrestor as close as possible to the valve causing the problem. For appliances like washing machines, this means on the hot and cold hose bibs. You generally need one arrestor for each problematic appliance valve (one for hot, one for cold).

The principle here is "stop the problem at the source." The shockwave originates at the valve. The further the arrestor is from that valve, the more pipe has to endure the pressure spike before the wave reaches the cushion. It will still work, but not as effectively. I remember a project where we had a huge CNC machine that had a vibration issue. We tried adding dampeners to the machine's feet, but it didn't solve the problem. The real solution was to rebalance the high-speed spindle itself—the source of the vibration. It’s the same logic. For a single problematic faucet, an arrestor on its supply line is key. For a washing machine with its fast-acting hot and cold solenoid valves, you need two arrestors, one for each supply line. If your whole house has issues, a plumber might install larger ones on the main branches after the water meter.

Can I install a water hammer arrestor myself? Are arrestors easy to install?

Hesitant to try a plumbing project on your own? The fear of creating a leak can stop you from attempting even a simple fix, leaving you to live with the problem.

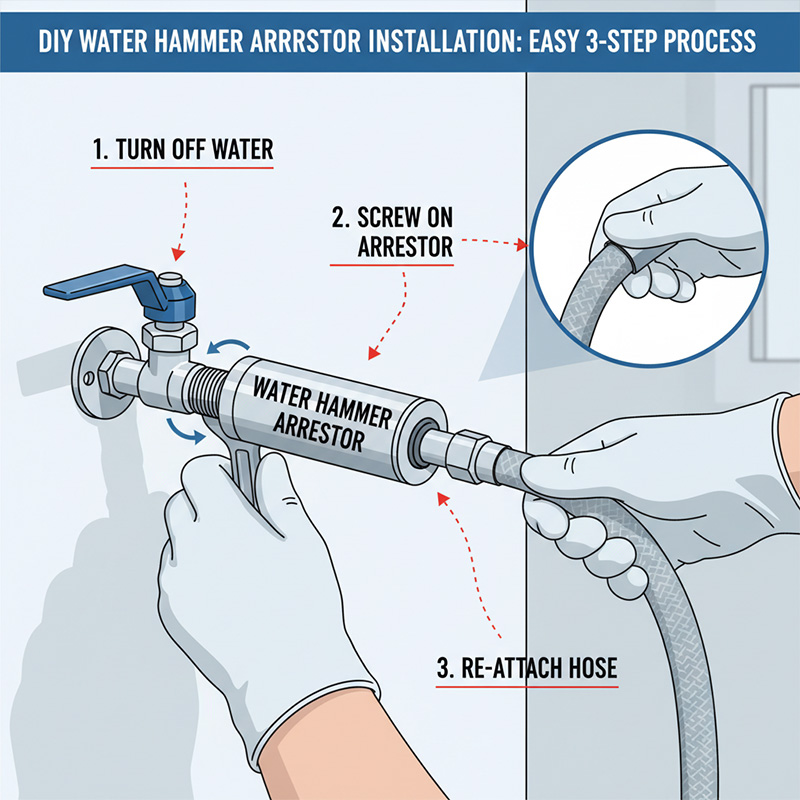

Yes, you can often install them yourself. Screw-on arrestors that attach to appliance hose bibs are extremely easy to install. They simply thread on between the shutoff valve and the appliance's supply hose, requiring only a pair of pliers or a wrench.

This type of arrestor is a fantastic example of user-centered design. The engineers took a professional component and adapted it for the DIY market by using a universally understood connection: the standard garden hose thread. The installation process is deliberately made to be foolproof. Jacky, you'd appreciate that the design constraints here were not just performance, but also ease of installation for a novice. It's a three-step process: turn off the water, unscrew the hose, screw on the arrestor, and re-attach the hose. The only skill required is ensuring the connection is tight enough to not leak. In-line models that require soldering are a different story, but for the most common cause of water hammer—appliances—the DIY solution is wonderfully simple and accessible. It empowers the homeowner to solve a problem that sounds complex but has been given a simple fix.

Why are my pipes still banging with a water hammer arrestor?

Installed an arrestor but the banging didn't stop? This is incredibly frustrating and makes you feel like you've wasted your money on a product that doesn't work.

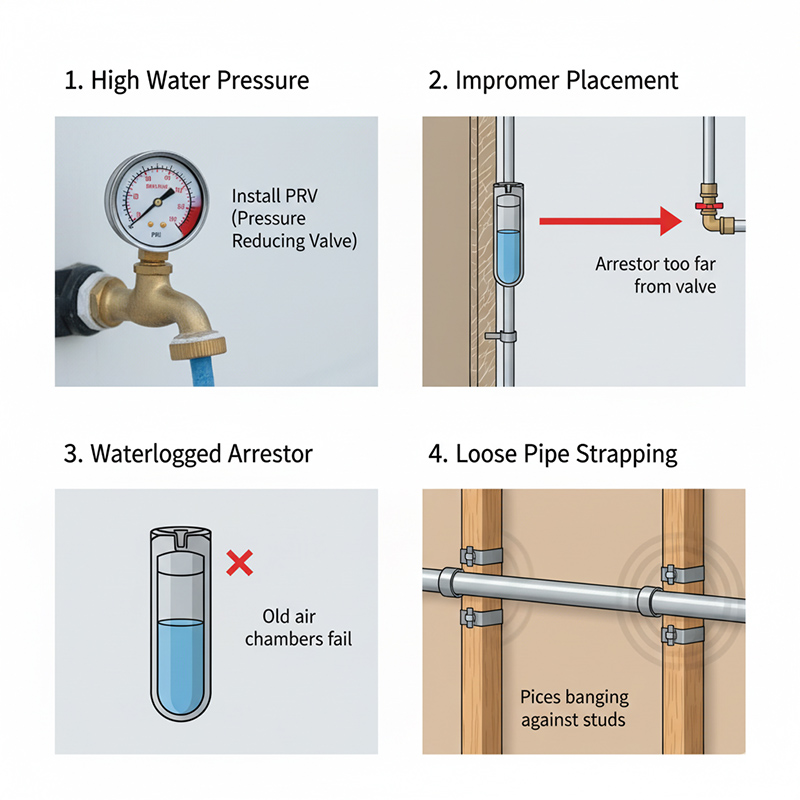

If pipes still bang, the arrestor may be waterlogged (failed), improperly placed, or undersized for the shockwave. The issue could also be unrelated to water hammer, such as loose pipe strapping allowing pipes to bang against studs, or excessively high household water pressure.

This is where we move from a simple fix to real diagnostics, which is a core skill for any engineer or designer. The first step is to check for other variables. Put a pressure gauge on an outdoor spigot. Is your home's water pressure above 80 PSI? If so, the main problem might be high system pressure, which requires a Pressure Reducing Valve (PRV), not an arrestor. Second, re-check the arrestor's placement. Is it right at the problem valve? Third, consider the arrestor itself. Cheaper, older "air chamber" style pipes can become waterlogged over time, rendering them useless. Modern piston-style arrestors are far more reliable. Finally, listen carefully. Is it a sharp "bang" or a dull "thud"? A thudding sound might be a poorly secured pipe moving around in the wall. Diagnosing a problem, as you know, Jacky, is about systematically eliminating possibilities until you find the true root cause.

Does a water hammer arrestor go on hot or cold? How long do they last?

Getting ready to install, but now you're wondering which line to put it on? Choosing the wrong line could mean you only solve half the problem, or none of it.

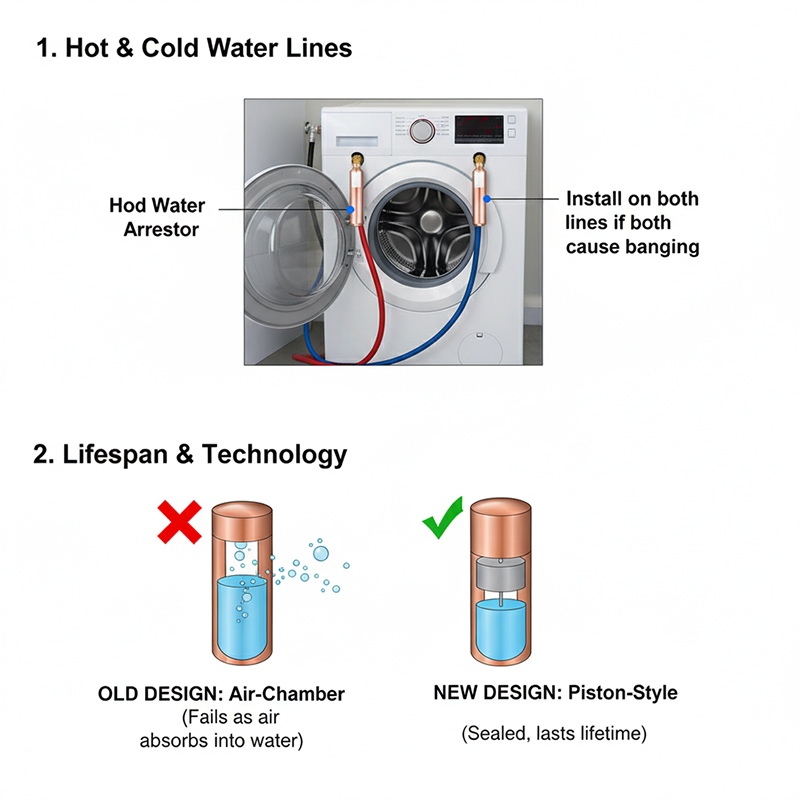

You should install an arrestor on the specific line that is causing the bang. If your washing machine bangs when both hot and cold water shut off, you need one on both lines. Quality, piston-style water hammer arrestors are maintenance-free and designed to last for the life of the plumbing system.

The logic is simple: the device needs to be on the line experiencing the shock. Since many modern appliances use separate solenoid valves for hot and cold intake, each one can independently create water hammer. So, you treat them as two separate problems that require two separate solutions (arrestors). As for longevity, this is purely a function of design quality and materials. An old-school "air chamber" (an empty, capped vertical pipe) will fail as the air is absorbed by the water over a few years. A modern, piston-style arrestor, which I've been discussing, uses a permanent O-ring and a sealed charge of gas. Because the air/gas and water never touch, it can't become waterlogged. This is a design that accounts for long-term failure modes. It's a "fit and forget" component, which from a product designer's viewpoint, Jacky, is the gold standard for a utility product.

Conclusion

A water hammer arrestor is an essential, elegantly designed device. It safely absorbs destructive pressure spikes, protecting your plumbing, stopping noise, and providing peace of mind through simple, effective engineering.