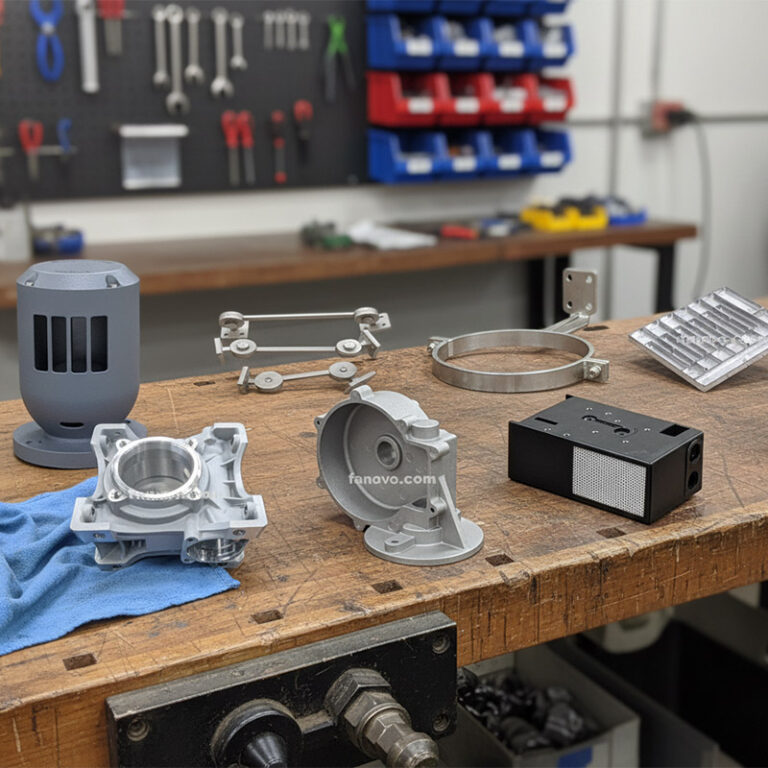

Fanovo is a premier manufacturing factory and ISO 9001 certified supplier specializing in the production of high-quality, custom metal casting parts. We are the trusted foundry partner for OEMs, industrial equipment manufacturers, and wholesale suppliers who require precision-engineered components with superior structural integrity and complex geometries.

By leveraging a range of advanced casting processes, we transform raw metal into near-net-shape parts that form the backbone of your products. Partnering with the Fanovo factory means gaining access to comprehensive engineering support, state-of-the-art foundry facilities, and in-house finishing capabilities, all managed through a seamless, factory-direct supply chain.

Fanovo: Beyond a Traditional Foundry

We provide an integrated solution that goes from initial design consultation to finished, ready-to-assemble components.

Process Optimization for Your Part: We don’t force a one-size-fits-all solution. Our engineers help you select the ideal casting method—investment, die, or sand casting—to perfectly balance your requirements for cost, surface finish, dimensional accuracy, and production volume.

Engineering for Manufacturability (DFM): Before any metal is poured, our experts collaborate with your team to optimize your part design for the casting process. This crucial step reduces material waste, minimizes porosity, improves strength, and lowers your final per-unit cost.

In-House Precision CNC Machining: A raw casting is rarely the final product. Our vertically integrated facility includes a full-service CNC machine shop. We handle all necessary secondary operations—milling, turning, drilling, and threading—to machine your cast parts to their final, tight-tolerance specifications. This one-stop-shop approach streamlines your supply chain and ensures total quality control.

Guaranteed Quality & Material Integrity: As your factory partner, we take quality personally. We use spectrometers to verify alloy composition, CMMs for dimensional accuracy, and offer non-destructive testing (like X-ray and dye penetrant) to ensure your parts are free from internal defects. Our entire process is governed by our strict ISO 9001 QMS.