Struggling with unstable pressure in your systems? The wrong valve choice can lead to inefficiency, noise, and component failure. This can be a costly mistake for any business.

A pressure differential valve automatically maintains a constant pressure difference between two points. This simple job is key to balancing flow, protecting pumps, and improving system efficiency.

I know these components can seem complicated. Finding a reliable one adds another challenge. As an engineer with over 15 years in this field, I have seen many system problems caused by misunderstood valves. This guide will break down what you need to know. I will cover everything from basic principles to finding a good supplier. Let me walk you through it.

I know these components can seem complicated. Finding a reliable one adds another challenge. As an engineer with over 15 years in this field, I have seen many system problems caused by misunderstood valves. This guide will break down what you need to know. I will cover everything from basic principles to finding a good supplier. Let me walk you through it.

What is the purpose of a pressure differential valve?

Are you wondering where this valve actually fits in a system? Many people mistake it for a simple flow controller. Its job is much more specific and important for the health of a system.

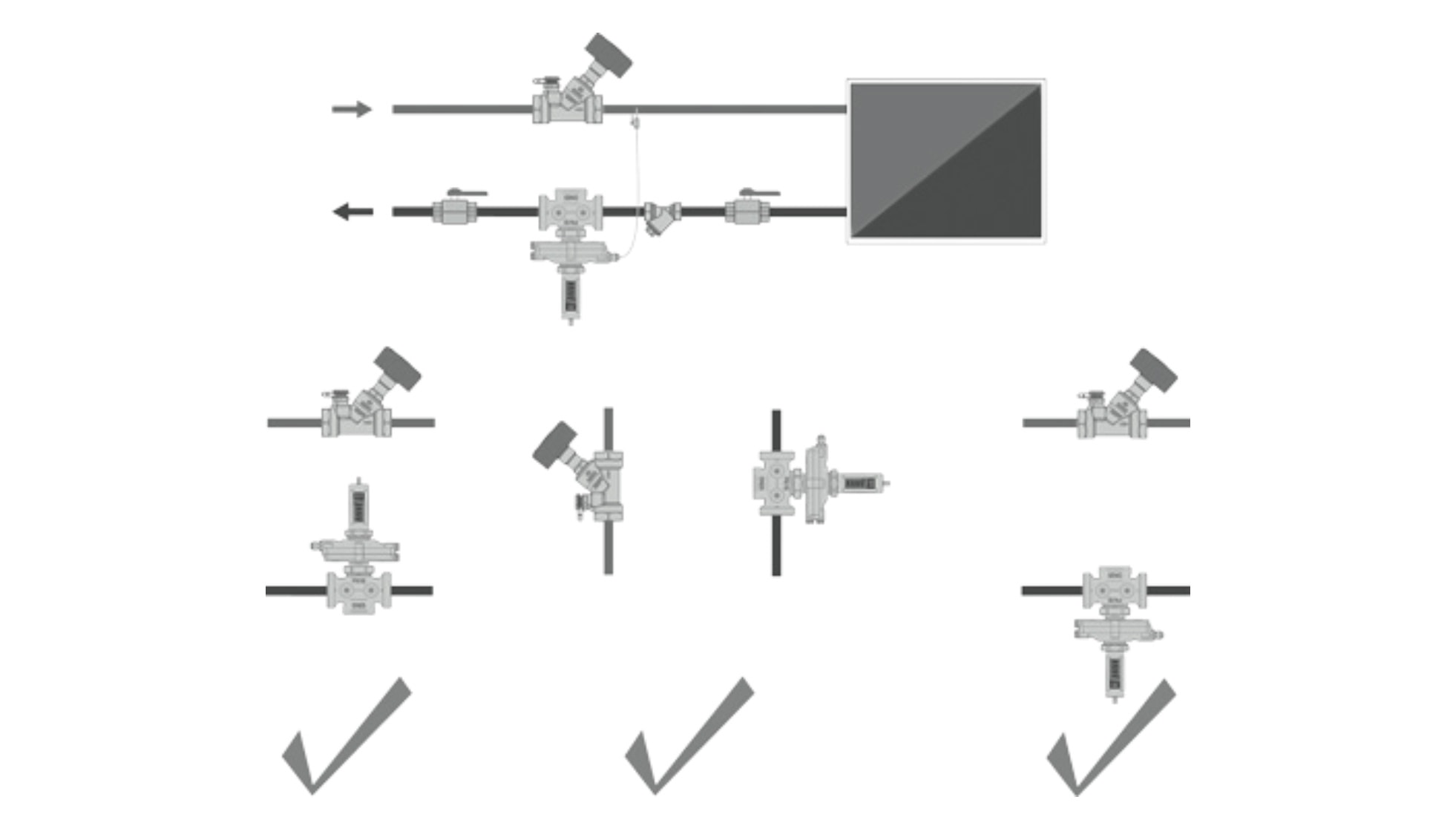

A pressure differential valve is used to maintain a stable pressure drop across a circuit or main pipes. This ensures other components, like control valves, work correctly under steady conditions.

I think of it as a gatekeeper for pressure. Imagine a large heating system with many zones. Different zone valves open and close all the time. This can make the overall system pressure change a lot. These changes can cause problems. You might get noisy pipes, not enough flow to some areas, and too much work for the pump. A differential pressure valve is usually put on a bypass line. It absorbs these pressure changes. It makes sure the pump always works against a steady pressure. This saves energy and makes the pump last longer. I once solved a constant "noisy pipe" problem in a big building. I just had to install one of these valves correctly. It made the whole network stable.

I think of it as a gatekeeper for pressure. Imagine a large heating system with many zones. Different zone valves open and close all the time. This can make the overall system pressure change a lot. These changes can cause problems. You might get noisy pipes, not enough flow to some areas, and too much work for the pump. A differential pressure valve is usually put on a bypass line. It absorbs these pressure changes. It makes sure the pump always works against a steady pressure. This saves energy and makes the pump last longer. I once solved a constant "noisy pipe" problem in a big building. I just had to install one of these valves correctly. It made the whole network stable.

How does a differential pressure control valve work?

Does the inside of these valves seem like a puzzle? The way they work is actually quite simple. It uses basic physics. This makes them very reliable without needing any electronics.

It works by using a spring-loaded diaphragm or piston. High-pressure fluid pushes on one side, and low-pressure fluid pushes on the other. This movement opens or closes the valve to keep a set pressure difference.

Let me explain it more simply. The valve has two small ports. They connect to the high-pressure side and the low-pressure side of the piping it monitors. Inside the valve, these pressures push on a diaphragm. A large spring, which you can adjust, pushes back against the pressure from the high side. You adjust this spring to set the pressure difference you want. For example, if you set it to 5 psi, the valve will adjust its opening. It makes sure the pressure difference between the two points is never more than 5 psi. If the difference increases, the valve opens more to let some flow bypass and bring the pressure down. If the difference decreases, the valve closes a little. It is a simple, mechanical system that works by itself.

Let me explain it more simply. The valve has two small ports. They connect to the high-pressure side and the low-pressure side of the piping it monitors. Inside the valve, these pressures push on a diaphragm. A large spring, which you can adjust, pushes back against the pressure from the high side. You adjust this spring to set the pressure difference you want. For example, if you set it to 5 psi, the valve will adjust its opening. It makes sure the pressure difference between the two points is never more than 5 psi. If the difference increases, the valve opens more to let some flow bypass and bring the pressure down. If the difference decreases, the valve closes a little. It is a simple, mechanical system that works by itself.

What are the three main types of pressure control valves?

Do you find all the different pressure valves confusing? Using the wrong one is a common mistake. It can lead to system damage. Let's look at the three main types you will find.

The three main types are pressure reducing valves, pressure relief valves, and pressure sustaining valves. Each one has a very different job in controlling the pressure in a system.

I have worked with all three types many times. It is very important to know the difference. This simple table can help make it clear.

I have worked with all three types many times. It is very important to know the difference. This simple table can help make it clear.

| Valve Type | Primary Function | Typical Application | How It Works |

|---|---|---|---|

| Pressure Reducing Valve | Lowers a high inlet pressure to a steady, lower outlet pressure. | Domestic water supply, protecting appliances. | It senses the pressure downstream and closes a little to keep it at the set point. |

| Pressure Relief Valve | Protects a system from too much pressure by opening and letting fluid out. | Boilers, pressurized tanks, as a safety device. | It stays closed until pressure goes above a set limit, then it opens all the way. |

| Pressure Sustaining Valve | Keeps a minimum pressure at its inlet by relieving any extra pressure. | Pump discharge lines, keeping pressure in one area. | It stays open but adjusts to make sure the upstream pressure does not drop too low. |

A differential pressure valve is a type of sustaining valve. But its purpose is to maintain a pressure difference, not a single pressure point.

How do you properly test a pressure differential valve?

Is an untested valve a risk you are willing to take? A valve that is not working right cannot protect your system. The good news is that testing is a simple job.

To test a pressure differential valve, you must check that it opens and closes at the correct set pressure difference. This means you have to isolate the valve and use gauges to watch it work.

From my experience, a test on a workbench is the most reliable way before you install it. First, I connect pressure gauges to both the inlet and outlet ports of the valve. Then, I use a hand pump or pressurized water to add pressure to the inlet side. I keep the outlet at a lower pressure. I slowly increase the inlet pressure. This creates a pressure difference. I watch the gauges very closely. I need to see at what exact pressure difference the valve starts to open and let flow through. This opening point should match the number set on the valve's adjustment dial. I also check to make sure it closes smoothly when the pressure difference goes down. Doing this quick test gives me confidence that the valve will work as it should in the system.

What is the difference between a DPCV and a PICV?

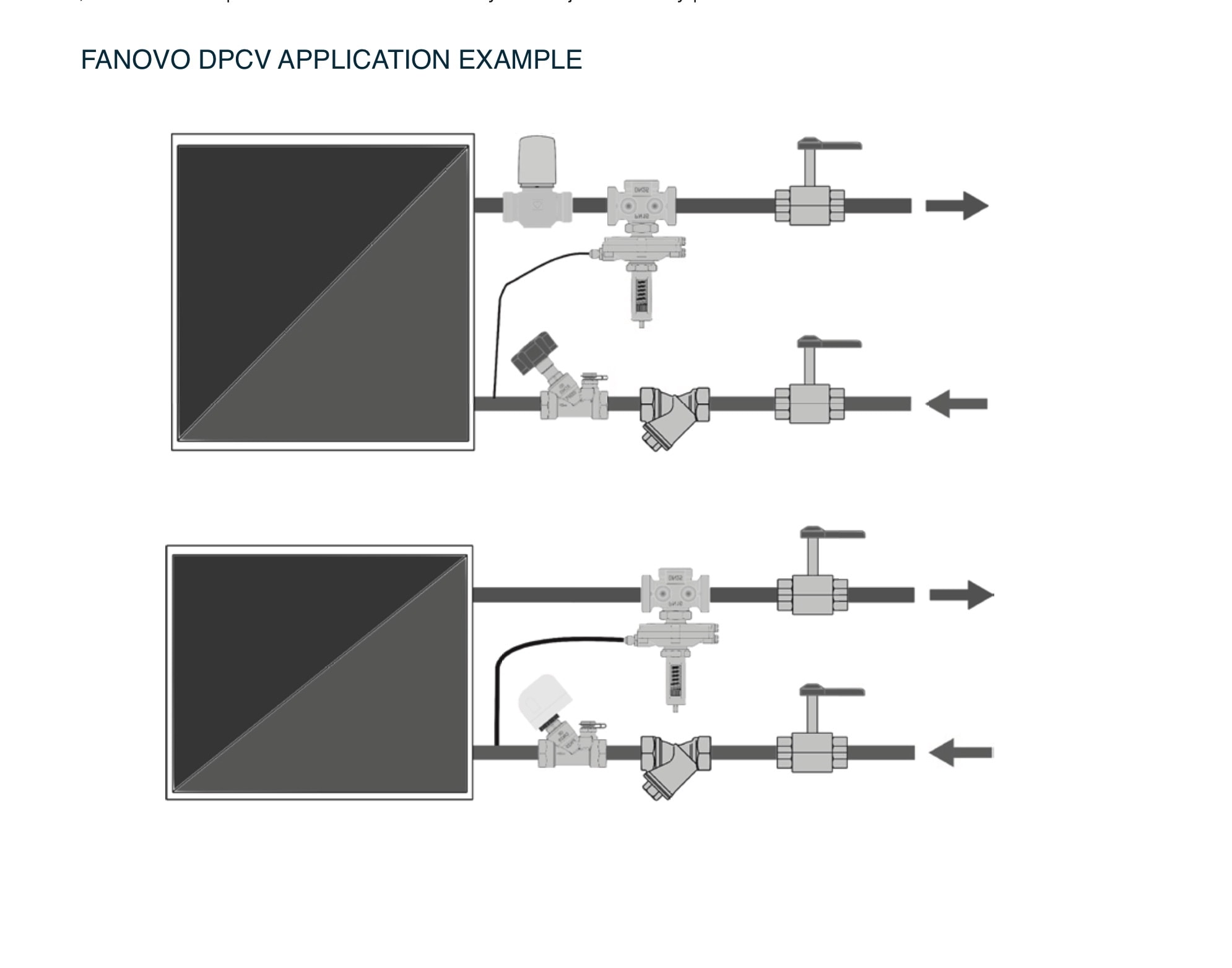

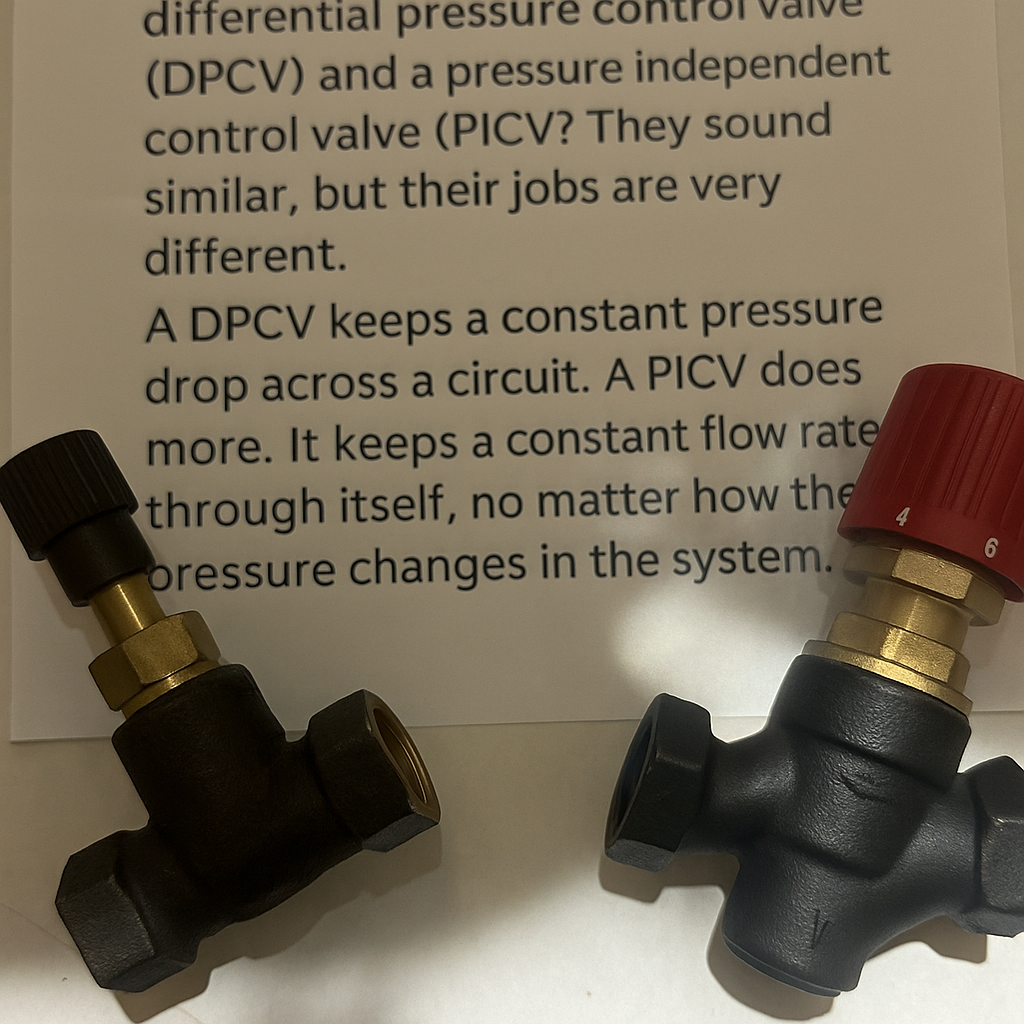

Are you trying to decide between a differential pressure control valve (DPCV) and a pressure independent control valve (PICV)? They sound similar, but their jobs are very different.

A DPCV keeps a constant pressure drop across a circuit. A PICV does more. It keeps a constant flow rate through itself, no matter how the pressure changes in the system.

I get asked about this choice often. The important thing is what you want to control. A DPCV is great for balancing the whole system, like across the main pipes of a heating circuit. It makes sure all the branches get a stable pressure supply. A PICV is used for controlling a single unit, like an individual fan coil or radiator. It combines three jobs into one part: a differential pressure controller, a control valve, and a balancing valve. This makes installation easier. It also makes sure the correct amount of flow goes to that one unit. This improves energy efficiency and comfort. So, for big system stability, I use a DPCV. For exact control of one unit, I choose a PICV.

How can you find a reliable pressure differential valve supplier?

Is finding reliable parts one of your biggest challenges? A low-quality valve can damage your company's reputation. Finding a true partner, not just a seller, is very important for success.

You can find a reliable supplier by looking for manufacturers with long experience, complete technical data, industry certifications, and good customer support, like a dedicated person to help you.

Over my career, I have learned that the starting price is only one part of the story. I always look for a supplier who can give me complete technical details and material test reports. Certifications like ISO 9001 are very important. They show that the company cares about quality control. I also value manufacturers like FANOVO. They have over 20 years of experience making parts for European and American markets. This tells me they understand the standards and quality that I expect. A supplier who offers training to their own team and provides good customer service is a supplier who wants me to succeed. You should look for that kind of partnership.

My Insights on the Global Market

From my job in the industry, I have seen a big change in global manufacturing. For years, we mostly looked to Western Europe or the US for high-quality valves. But things are different now. I have seen Chinese manufacturing grow incredibly fast, especially for pressure differential valves. The technology and quality for residential and commercial parts now match the Western brands. They also often offer a much better price.

Recent world events, like the conflict in Ukraine, have made this shift happen even faster. Many Western brands left the Russian market. This created a huge opportunity. I have personally seen companies like FANOVO step in and do very well. They were able to provide high-quality HVAC and plumbing parts to fill that empty space. Their reputation has grown a lot. In my opinion, FANOVO has become a leader in places like Russia. They did not just fill a space, they delivered excellent products. Their plan to grow into more countries is built on a strong base of providing great valves for heating and plumbing systems all around the world.

Conclusion

Choosing the right pressure differential valve is key for a stable system. Understanding how they work, how to test them, and where to find a quality partner ensures your project's success.