Что такое клапан разностного давления и почему он важен для российских отраслей?

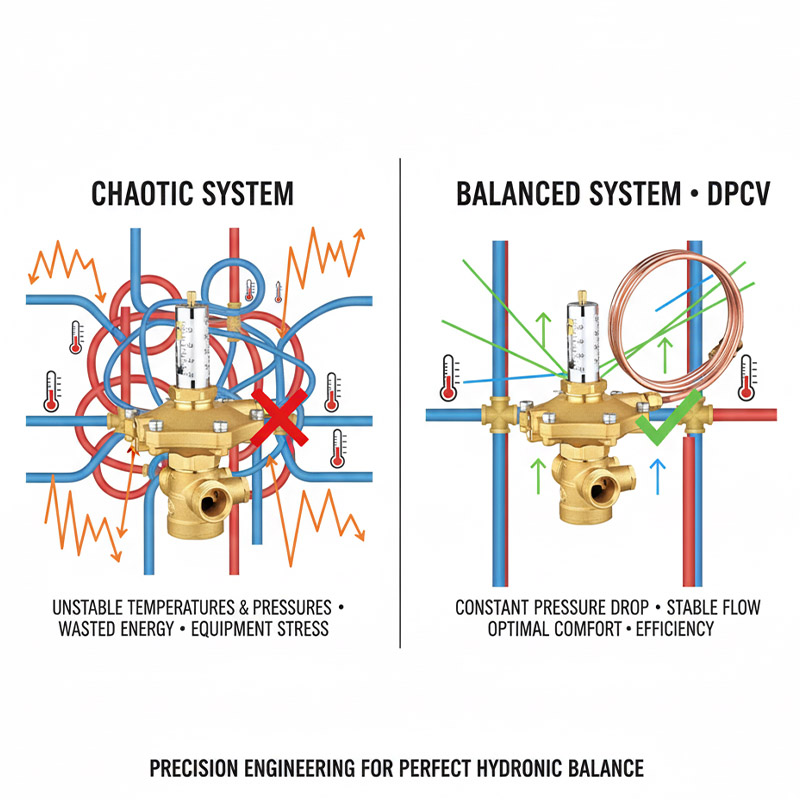

You're constantly battling unstable temperatures and fluctuating pressures in your building's heating systems. This fight leads to wasted energy, uncomfortable occupants, and the constant threat of equipment failure.

The solution is a surprisingly simple mechanical device: a Differential Pressure Control Valve (DPCV). This valve automatically maintains a constant pressure drop across a circuit, ensuring stable flow to every user regardless of demand changes elsewhere in the system.

This is a classic systems engineering problem, Jacky. It reminds me of trying to balance the cooling channels in a huge, complex injection mold. If you don't control the flow to each circuit, some parts of the mold get too hot and some get too cold, resulting in warped parts and a ton of scrap. We used flow regulators to solve that. A DPCV is the exact same principle, but for an entire building or industrial plant. It's a simple, reliable way to bring a chaotic system into perfect balance.

How Can You Tame the Elements in the Constant Battle for System Stability in Russia?

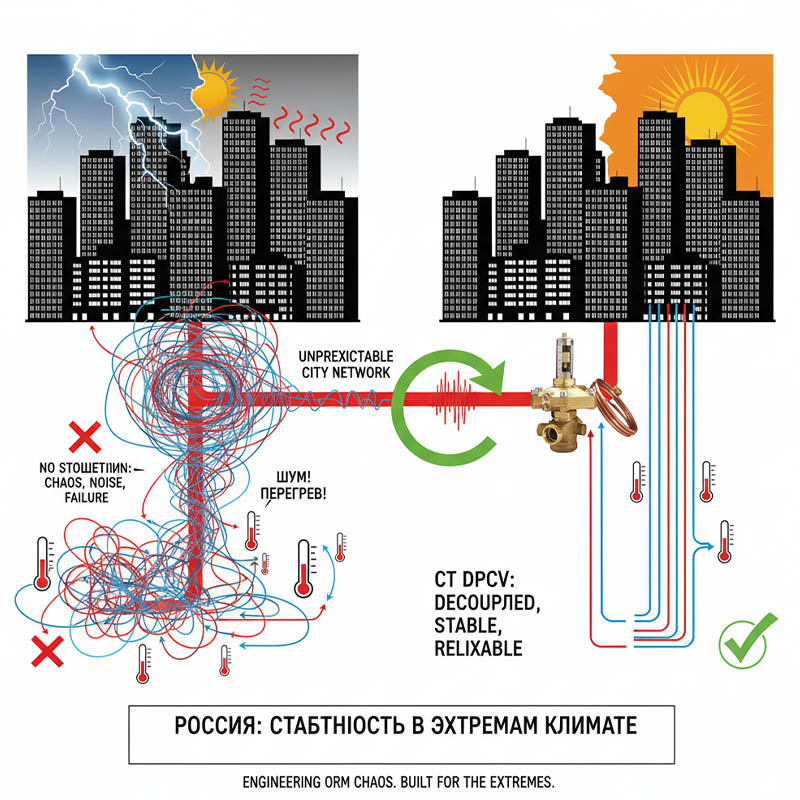

Russia's extreme climate, from bitter winters to hot summers, creates massive and rapid swings in heating and cooling demand. This chaos puts enormous stress on your systems.

The key is to create stable "micro-systems" that are insulated from the chaos of the main network. A DPCV acts as a gatekeeper for each branch, ensuring it gets a consistent pressure and flow no matter how wild the demand swings are upstream.

Think about a district heating plant serving thousands of apartments across a city. When a whole block of buildings turns their heat down in the morning, a massive pressure wave travels through the main pipes. Without protection, this surge hits other buildings, causing noisy pipes, overheating, and stressing thermostatic radiator valves (TRVs) until they fail. A DPCV on each building's connection absorbs this surge. It ensures that, inside your building, the pressure remains stable and predictable. As a designer, Jacky, you know this concept as "decoupling." You are decoupling the building's internal system from the unpredictable external supply, which is the only way to guarantee reliable performance in such a dynamic environment.

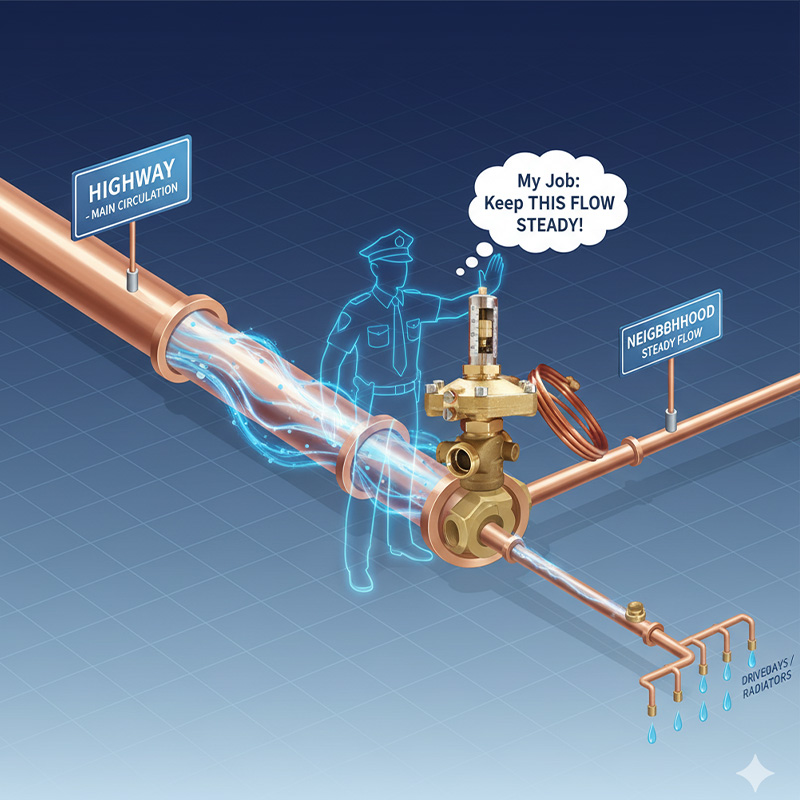

What is the "Intelligent Traffic Manager" for Your Fluid Systems?

Your fluid system is like a city's road network, with fluctuating traffic. Without control, you either get gridlock (no flow) or reckless speeding (pressure surges).

A Differential Pressure Control Valve is that intelligent traffic manager. It constantly senses the pressure difference in its local "neighborhood" and automatically adjusts to keep the flow of water smooth and consistent, regardless of the chaos on the main "highway."

Let's break down this analogy. The main circulation pump is the city's power station. The large primary pipes are the highways. The smaller pipes feeding different floors or zones are the city streets. The individual radiator valves are the driveways. A DPCV is like a skilled traffic cop placed at the off-ramp from the highway to a specific neighborhood. It doesn't care about the traffic jams or wide-open speeds on the highway. Its only job is to ensure the volume of cars entering the neighborhood streets is always steady and calm, allowing the little driveways at the end to function perfectly. It brings order to a potentially chaotic system through purely mechanical, automatic control.

Where Does a DPCV Matter Most in Powering Russian Industry and Comfort?

In any large-scale hydronic system, some users get too much flow and others get too little. This leads to wasted energy, premature equipment failure, and constant complaints.

DPCVs are most critical in three areas that form the backbone of Russia's infrastructure: district heating for residential comfort, large HVAC systems in commercial centers, and industrial process lines where equipment protection is paramount.

This is where the theory meets the real world, Jacky. Let's look at the three most critical applications.

In a massive apartment block in Novosibirsk, the apartments closest to the main riser often get blasted with high pressure, causing noisy, overheating radiators. Meanwhile, the apartment at the far end of the hall is cold. This is because the high flow is not balanced. A DPCV installed on the riser for each vertical section of the building ensures every section gets the same operating pressure. This allows the simple thermostatic valves on each individual radiator to do their job properly, guaranteeing every single apartment gets a fair and steady share of warmth.

3.2. Robust HVAC: Guaranteeing Consistent Climate Control in Megacities like Moscow & St. Petersburg

Consider a modern skyscraper in Moscow City. The south side baking in the sun needs maximum cooling, while the north side needs much less. Without control, the high demand from the south side's air handling units would "steal" all the chilled water flow from the north side. By placing a DPCV on each zone's circuit, you guarantee that every zone has a stable pressure to draw from. This ensures the Variable Air Volume (VAV) systems can operate efficiently, providing consistent and reliable climate control across the entire building, no matter the external conditions.

3.3. Industrial Processes: Protecting Expensive Equipment from Destructive Pressure Surges

In a Siberian gas processing plant, a heat exchanger worth hundreds of thousands of euros requires a very specific and stable flow rate of coolant to operate safely. But elsewhere in the plant, a large reactor might suddenly demand a huge volume of water, causing a pressure drop across the whole facility. That pressure fluctuation can starve the heat exchanger of coolant, causing it to overheat and fail catastrophically. A DPCV installed directly before the heat exchanger acts as a personal bodyguard, ensuring that no matter what happens in the rest of the plant, its flow of coolant remains absolutely constant, protecting that critical asset from damage.

How Does a DPCV Directly Impact Your Bottom Line, Turning Challenges into Solutions?

Wasted energy, unexpected equipment failures, and complaints from occupants are not just annoyances; they are direct hits to your operational budget.

A DPCV directly reduces these costs. By optimizing the system, it slashes pump energy consumption, eliminates the pressure surges that kill equipment, and provides the stable temperatures that ensure comfort and compliance with building codes.

-

What Key Specifications Matter When Choosing a DPCV for the Demanding Russian Market?

The market is flooded with valves, and a cheap option looks tempting. But a valve failure during a -30°C winter is not just an inconvenience; it's a disaster.

For the demanding Russian market, you must prioritize specifications that guarantee reliability: a robust body made of ductile iron or brass, a wide operating temperature range, a high pressure rating (PN16/PN25), and a proven track record from a reputable manufacturer.

This is not the place to cut corners, Jacky. Procuring a critical component like this is the same as choosing the steel for a high-volume mold. You must choose for durability and performance, not just price. Key things to demand from your supplier are:

- Material Strength: The body must be able to withstand the incredible thermal stress of going from ambient temperature to high heat, day after day. Forged brass or ductile iron are the standards.

- Pressure and Temperature Ratings: Ensure the valve is rated for the maximum pressure and temperature of your system, with a healthy safety margin. PN16 (16 bar) is a common minimum.

- Leak-Proof Design: Look for valves with high-quality EPDM or Viton seals that won't harden or crack in extreme cold or heat.

- Proven Reliability: Partner with a manufacturer who understands the Russian market and has a history of their products performing reliably in its extreme conditions.

Why is a DPCV More Than a Component, but a Strategy for Unshakable System Reliability?

You can continue to chase problems, reacting to pipe noise here and a cold room there. It's an endless, frustrating, and expensive game of whack-a-mole.

Installing DPCVs is a fundamental shift in strategy. It's moving from a reactive, break-fix approach to a proactive, systems-design approach. You are engineering a balanced, resilient, and self-regulating system that prevents problems from ever happening.

This is the ultimate goal for any engineer. You are building inherent stability into the design. In mold making, we call this a "robust process." We design the mold's cooling and venting so well that it can handle small variations in melt temperature or pressure and still produce a perfect part every time. A building fitted with DPCVs has a robust hydronic system. It can handle massive demand swings from the utility and still provide perfect comfort and efficiency inside. It's not just a part; it's a strategy that creates a foundation of unshakable reliability for the entire operation.

Conclusion

A Differential Pressure Control Valve is an essential investment for Russia's industries. It is the key to creating efficient, reliable, and comfortable buildings by conquering system instability at its source.