How Can a Simple Adapter System Drastically Cut Your Installation Time and Labor Costs?

Your setup team wastes hours with pipe wrenches and thread tape. Each connection is slow and risks leaks, blowing out your labor budget and your project timeline.

The right fire adapter system, like a Storz or Camlock, allows for instant, tool-free connections. It replaces minutes of manual work per fitting with a few seconds of simple action.

This question takes me back to setting up a huge, complex automotive mold for a bumper fascia. It had something like 48 individual cooling lines. The setup team, two good guys, spent an entire 8-hour shift just plumbing that tool with traditional threaded NPT fittings. They were struggling with wrenches in tight spaces, dealing with sealant, and fixing pesky drips. I watched them and thought, "This is insane. We're paying for 16 hours of skilled labor just to connect water lines." That one experience made me obsessed with finding faster, smarter, and more reliable ways to connect our systems. The cost isn't in the fitting; it's in the time spent fighting with it.

What Makes a Quick-Connect Adapter System So Much Faster Than Traditional Fittings?

You specify standard threaded fittings because it's what you've always done. But on the floor, your assembly team is fighting with heavy wrenches in tight spaces, and every connection is tedious.

A quick-connect system's speed comes from its design. Storz adapters use a simple quarter-turn mating action, and Camlocks use levers. Both designs are tool-free and provide positive locking feedback, turning a multi-minute task into seconds.

As a designer, you appreciate mechanical elegance. That's what a quick-connect system offers. The beauty of a Storz or Camlock system isn't just about being fast; it's about being repeatable and certain. With a threaded NPT fitting, you're always guessing. Is it tight enough? Too tight? Will it leak? With a quarter-turn Storz connection, you simply engage the lugs and turn until they stop. With a Camlock, you close the arms, and they snap shut. You feel and hear the connection happening. This positive feedback eliminates guesswork and the need for rework, making the process not only faster but also far less prone to operator error.

A Tale of Two Connections: NPT vs. Quick-Connect

| Feature | Traditional NPT Threaded Fitting | Quick-Connect System (Storz/Camlock) |

|---|---|---|

| Action Required | Multiple full rotations (5-8+ turns) | Quarter-turn or closing two levers |

| Tools Required | Two pipe wrenches, thread sealant/tape | None |

| Time per Connection | 2-5 minutes | 3-10 seconds |

| Risk of Error | High (cross-threading, over/under-tightening) | Low (provides positive locking feedback) |

How Do These Time Savings Actually Translate into Measurable Cost Reductions?

You're trying to justify a higher-cost component to management. It can be difficult to prove the ROI when they only see the initial purchase price of the adapters.

The cost savings are direct and easy to calculate. By multiplying the time saved per connection by the number of connections and the hourly labor rate, you can demonstrate a clear, rapid ROI.

Jacky, I know you have to prove the value of every component you spec. This is one of the easiest arguments you'll ever make. The upfront cost of a quick-connect system might be higher, but the investment is often paid back in a single complex tool change. You can build a simpleROI model to show your manager. The numbers don't lie. When you can take a process that takes hours and reduce it to minutes, the labor savings are immediate and substantial. This isn't just a small improvement; it's a fundamental change in how you manage setup costs, allowing you to reallocate that saved labor to more value-added tasks. It directly impacts the profitability of every single job.

The ROI on Speed: A Sample Calculation

| Metric | Traditional NPT System | Quick-Connect System (Storz) |

|---|---|---|

| Connections per Mold | 24 | 24 |

| Avg. Time/Connection | 3 minutes | 10 seconds (0.17 minutes) |

| Total Setup Time | 72 minutes | 4 minutes |

| Labor Rate (example) | $50/hour | $50/hour |

| Total Labor Cost | $60.00 | $3.33 |

| Savings Per Setup | - | $56.67 |

Are Quick-Connect Systems Reliable Enough for High-Pressure Mold Applications?

You worry that a "quick" connection is also a "weak" one. The idea of a fast-fitting failing under pressure and damaging an expensive mold is a designer's absolute nightmare.

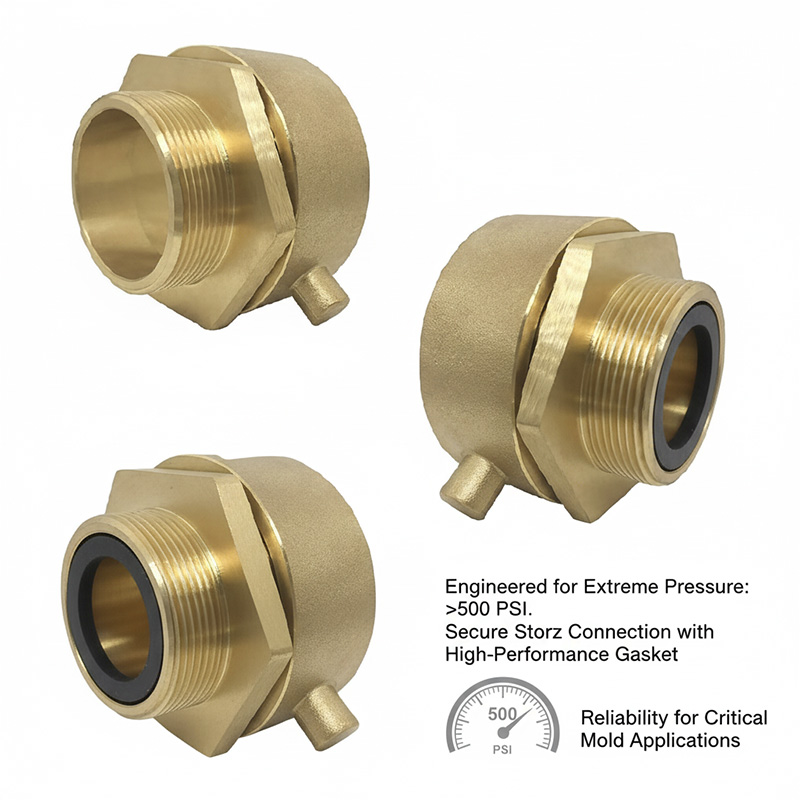

Yes, they are exceptionally reliable. High-performance forged adapters, especially Storz, are engineered for extreme-duty use in firefighting. Their design, combined with quality gaskets, creates a secure seal that often has a higher pressure rating than the hose itself.

This is a totally valid concern. Nobody wants to be responsible for a failed fitting that causes thousands in damage. But you have to remember the origin of these designs. Storz adapters were invented for firefighting, where failure is not an option. The connection gets tighter as internal pressure increases. High-quality Camlock fittings use precision-machined surfaces and robust arms to create a powerful clamping force. The key is specifying high-performance versions made from forged materials, not cheap cast ones. A forged aluminum or brass Storz adapter is incredibly tough and resists the daily abuse and vibration on a factory floor. In my experience, a properly installed quick-connect fitting is actually more reliable than a threaded fitting because it removes the variable of human error during tightening.

Conclusion

A quick-connect adapter system is a simple change that delivers huge returns. It saves time, cuts labor costs, and improves the operational efficiency of your most valuable molding assets.