What Do Industrial Buyers Really Look For in a Reliable Valve Partner?

You're facing immense pressure to prevent downtime. One bad valve can shut down an entire line, costing a fortune and damaging your company's reputation with downstream customers.

A truly reliable valve partner provides more than just a product. They deliver certified quality assurance, deep material expertise, consistent manufacturing processes, and responsive engineering support to guarantee performance and protect your operations.

Making things is my passion, but I've learned that you're only as strong as your weakest link. For many of my clients, that weak link turned out to be a component they didn't make themselves, like a valve. I remember a call from a client in a panic. Their entire assembly line was stopped because a batch of ball valves from a new, cheaper supplier was failing pressure tests. They saved a few dollars per unit but were now losing thousands of dollars an hour in downtime. This experience is all too common. An industrial buyer isn't just purchasing a part; they are purchasing reliability. They are buying peace of mind. So, when you're sourcing a critical component like a valve, the price tag is only one small part of the story. Let's break down what truly separates a simple vendor from a long-term partner.

Is 'Good Enough' Quality Actually Costing You a Fortune?

You approved a perfect "golden sample," but now the first production batch is showing a high failure rate. You're stuck sorting parts and facing costly recalls or warranty claims.

This inconsistency comes from a lack of robust quality systems. A true partner guarantees consistency through documented processes like ISO 9001, providing proof that every single valve meets the same high standard.

In industrial applications, consistency is everything. Anyone can make one good part. The real challenge is making ten thousand of them exactly the same. This is where you must look beyond the promises and ask for proof. A reliable partner doesn't just say they have "good quality"; they prove it with documentation. As a buyer, you have the right to ask for this. It's the foundation of trust.

Beyond the Golden Sample

The first sample you approve should be representative of mass production, not a one-off hero part. A good partner achieves this through strict process control. They don't change materials or tooling without notifying you.

The Power of Documentation

Ask for the paperwork that backs up their claims. This is non-negotiable for serious buyers. This includes Material Test Reports (MTRs) to certify the exact alloy being used, and Certificates of Conformance (CoC) that state the parts meet your specifications. For critical applications, you can even request batch-specific pressure test results. This paper trail is your insurance policy.

| Metric | Price-Focused Supplier | True Engineering Partner |

|---|---|---|

| Quality System | Informal or undocumented | ISO 9001 Certified (or similar) |

| Material Proof | "It's brass." | Provides Material Test Reports (MTRs) |

| Inspection | Basic spot checks | 100% testing on critical features |

| Consistency | Varies from batch to batch | High consistency, low variance |

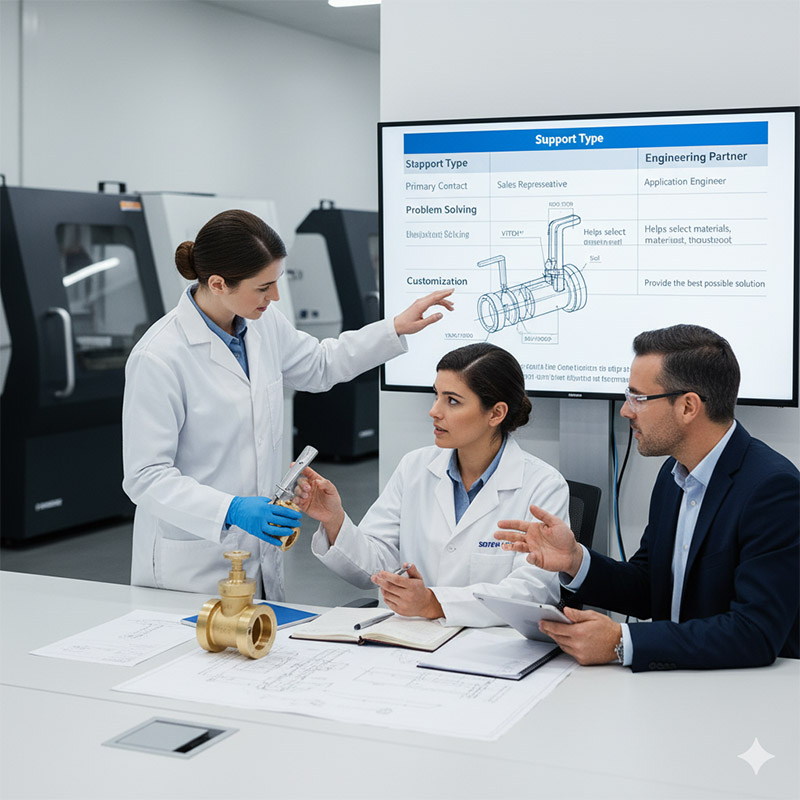

Does Your Supplier Just Sell Parts, or Do They Solve Problems?

You have a unique challenge—a specific temperature, pressure, or chemical compatibility issue. But the person you're talking to is just a salesperson who can only offer what's in the catalog.

You're left to guess, risking a design failure. An ideal partner provides direct access to their engineers who collaborate with you to find or create the perfect solution for your specific need.

A catalog is a starting point, not the final answer. In my experience, most industrial needs have at least one unique requirement. The supplier you choose must be able to move beyond their standard product list. The most valuable partners I've ever worked with acted more like engineering consultants than salespeople. They listen first and sell second. They ask about your operating pressures, your media, your temperature cycles, and your assembly process. This kind of collaborative relationship doesn't just get you a better part; it makes your own design process stronger and safer.

From Salesperson to Engineering Consultant

The first sign of a great partner is when your initial contact can either answer deep technical questions or immediately connect you with an engineer who can. You shouldn't have to fight to get technical support.

Customization is Key

Ask about their capability to make modifications. This could be as simple as a different handle, a specific color, or different thread standards. Or it could be more complex, like changing the seal material from standard NBR to Viton™ or EPDM for specific chemical or temperature resistance. A partner who is willing and able to customize is a partner invested in your success.

| Support Type | Standard Vendor | Engineering Partner |

|---|---|---|

| Primary Contact | Sales Representative | Application Engineer |

| Problem Solving | Refers to catalog | Helps select materials, troubleshoot |

| Customization | Limited to standard options | Offers design modifications |

| Goal | Sell a part from stock | Provide the best possible solution |

Can Your Partner Deliver When Your Production Line Can't Wait?

Your production schedule is set, but your component supplier just pushed back the delivery date again. Now your entire operation is at risk, and every day of delay is costing you money.

This uncertainty stems from a fragile or opaque supply chain. A dependable partner provides clear lead times, proactively manages their inventory, and communicates honestly and transparently about their production status.

| - | Supply Chain Aspect | Uncertain Supplier | Reliable Partner |

|---|---|---|---|

| Lead Times | Often shifts without notice | Stable and predictable | |

| Inventory | Little to no safety stock | Proactively manages raw materials | |

| Communication | Reactive (excuses after delay) | Proactive (updates before problems) | |

| Flexibility | Rigid and unresponsive | Works with you to meet deadlines |

Conclusion

Choosing a valve partner is about securing quality, expertise, and reliability. It's a strategic decision that protects your production, your budget, and your company's reputation in the long run.