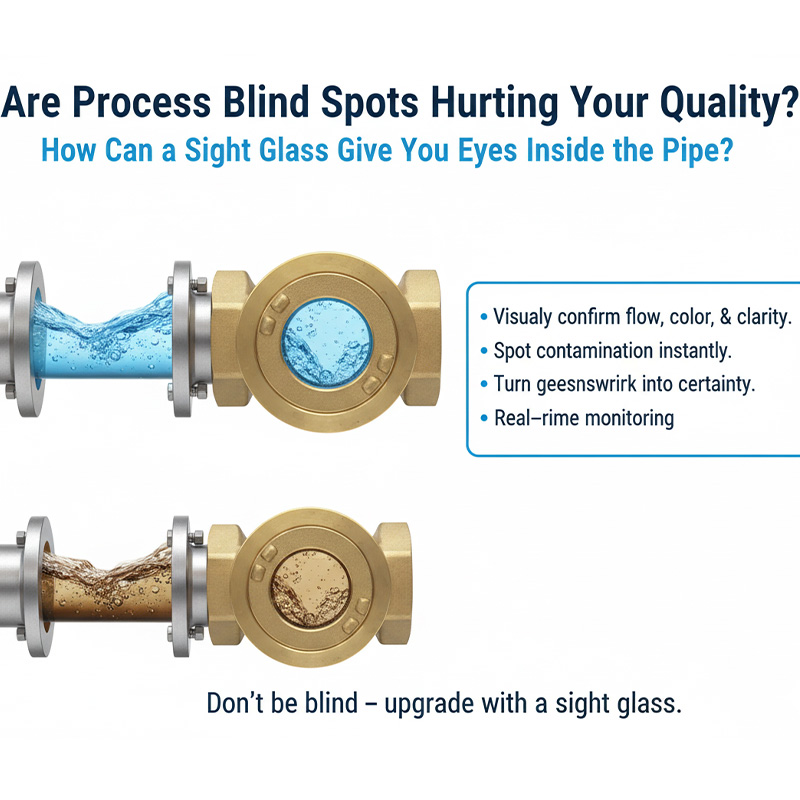

Are Process Blind Spots Hurting Your Quality, and How Can a Sight Glass Give You Eyes Inside the Pipe?

Your system is running, but you're blind to what's inside the pipes. Bad flow or contamination could be ruining your product, and you won't know until it's too late.

A pipe sight glass is a durable, transparent window installed directly in a pipeline. It allows you to visually confirm the flow, color, and clarity of fluids in real-time, turning guesswork into certainty and helping you spot costly problems instantly.

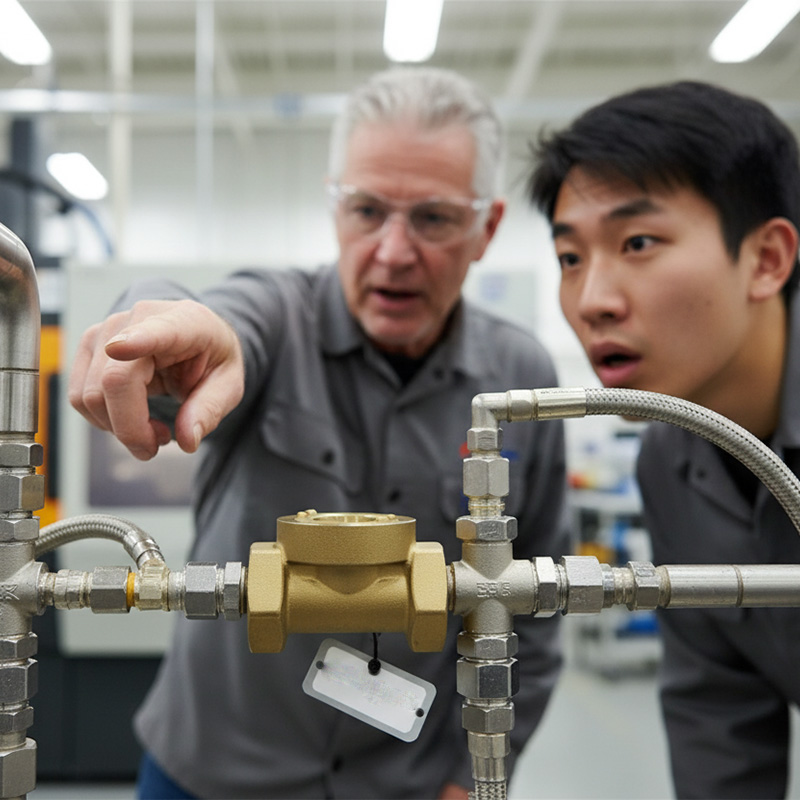

Jacky, this topic brings back a frustrating memory. We were molding a tricky polycarbonate lens and kept getting subtle haze marks. All a machine's sensors—pressure, temperature, flow rate—told us the mold's cooling circuit was perfect. We spent days troubleshooting. Finally, an old-timer suggested we check the return water line. We cut the hose open and saw tiny, almost invisible air bubbles. The pump was cavitating just enough to disturb the laminar flow, affecting the steel temperature by a fraction of a degree. A ten-dollar sight glass would have shown us the problem in ten seconds. It taught me a powerful lesson: sometimes, the most advanced sensor is your own eyes.

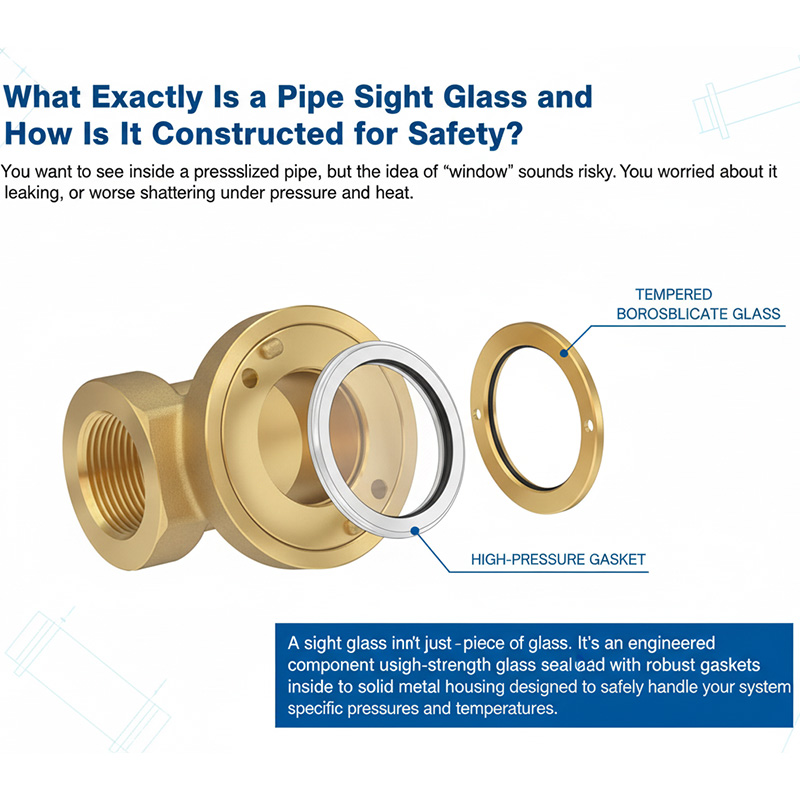

What Exactly Is a Pipe Sight Glass and How Is It Constructed for Safety?

You want to see inside a pressurized pipe, but the idea of installing a "window" sounds risky. You're worried about it leaking, or worse, shattering under pressure and heat.

A sight glass isn't just a piece of glass. It's an engineered component using tempered, high-strength glass sealed with robust gaskets inside a solid metal housing designed to safely handle your system's specific pressures and temperatures.

As a designer, you'll appreciate that these aren't just off-the-shelf parts. They are designed with safety factors just like any other critical industrial component. The reliability comes from the synergy of its materials.

The Key Components of a Sight Glass

- The Body (or Frame): This is the metal housing that holds everything together and connects to the pipe. It can be made from materials like Stainless Steel, Carbon Steel, or Brass. It typically connects via threads (like NPT) or flanges for larger, high-pressure systems.

- The Glass: This is the critical window. It's not ordinary glass. For most applications, it’s Borosilicate glass (like Pyrex), which is highly resistant to thermal shock and chemical attack. For lower pressures, it might be tempered soda-lime glass.

- The Gaskets: These are the unsung heroes. Placed on either side of the glass, they create the seal. The material must be compatible with the fluid and temperature. Common choices include Teflon (PTFE) for chemical resistance or Viton for high temperatures.

This robust sandwich construction ensures that the sight glass can safely contain the process fluid while giving you that priceless window inside.

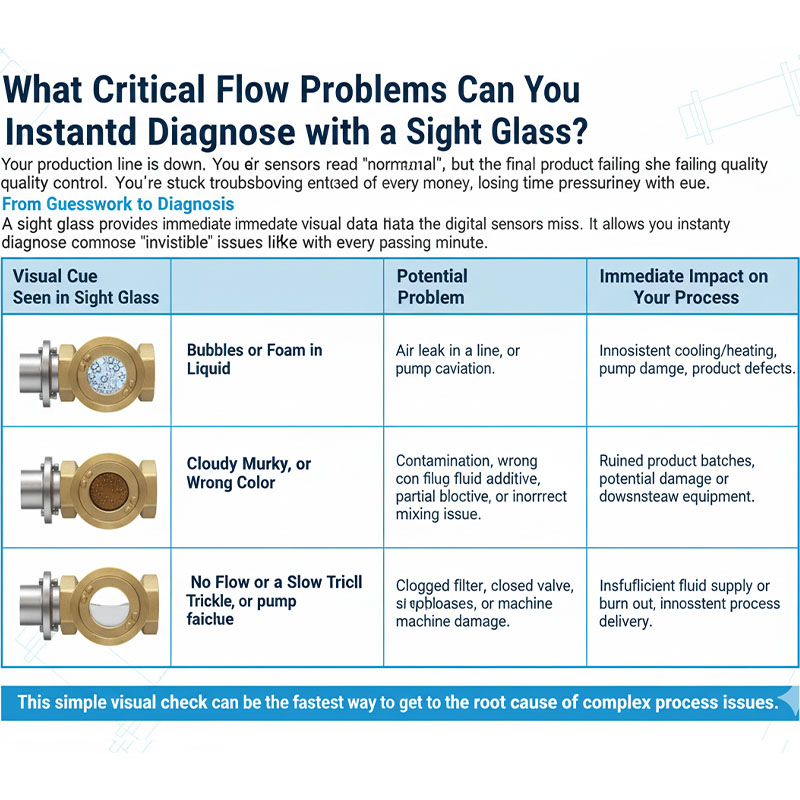

What Critical Flow Problems Can You Instantly Diagnose with a Sight Glass?

Your production line is down. The sensors read "normal," but the final product is failing quality control. You're stuck troubleshooting instead of producing, losing time and money with every passing minute.

A sight glass provides immediate visual data that digital sensors can miss. It allows you to instantly diagnose common "invisible" issues like aeration, contamination, partial blockages, or incorrect fluid mixing.

Think of it as adding a basic diagnostic screen to a black box system. Instead of relying solely on indirect data from sensors, you get to see the actual state of the fluid. This is invaluable for troubleshooting.

From Guesswork to Diagnosis

In my experience, what you see can solve problems far faster than what a spreadsheet of data tells you. Here are some common things I've learned to look for.

| Visual Cue Seen in Sight Glass | Potential Problem | Immediate Impact on Your Process |

|---|---|---|

| Bubbles or Foam in Liquid | Air leak in the line, or pump cavitation. | Inconsistent cooling/heating, pump damage, product defects. |

| Cloudy, Murky, or Wrong Color | Contamination, wrong fluid additive, or mixing issue. | Ruined product batches, potential damage to downstream equipment. |

| No Flow or a Slow Trickle | Clogged filter, closed valve, or pump failure. | System overheating, production halt, machine damage. |

| Pipe Only Partially Full | Insufficient fluid supply or siphoning effect. | Pump can run dry and burn out, inconsistent process delivery. |

This simple visual check can be the fastest way to get to the root cause of complex process issues.

Where Are the Most Strategic Places to Install a Sight Glass for Maximum Impact?

You're sold on the idea, but where do you put one? Placing a sight glass randomly in a long pipe might not give you the information you need, wasting the opportunity.

For maximum value, install sight glasses at critical transition points. Place them after pumps, before and after filters, on steam trap outlets, and on main return lines to confirm circulation.

Strategic placement is everything. You want the sight glass to tell you a story about a specific component or part of the process. You wouldn't put a temperature sensor a meter away from your mold, and the same logic applies here.

Strategic Placement for Process Visibility

Here are the four most valuable locations I recommend for installing sight glasses:

- Directly After a Pump: This is non-negotiable for me. It instantly tells you if the pump is primed and delivering a solid, bubble-free flow. Spotting cavitation here can save you from destroying a very expensive pump.

- Before and After Filters: Placing a sight glass on both the inlet and outlet of a filter housing is brilliant. It lets you see what kind of debris the filter is catching, and you can visually gauge when the filter is getting clogged by noticing a significant drop in flow on the outlet side.

- On Steam Trap Outlets: In systems that use steam for heating, this is crucial. A sight glass here shows if the trap is working correctly (discharging condensate) or failing—either blocked (damaging equipment) or blowing live steam (wasting huge amounts of energy).

- On Main Return Lines: Placing one just before the fluid re-enters the main tank or reservoir provides final confirmation that the entire loop is complete and flowing correctly.

Conclusion

A pipe sight glass is a simple, powerful tool that eliminates blind spots. It replaces risky assumptions with direct visual evidence, helping you protect your equipment, ensure quality, and solve problems faster.