Is Frequent Boiler Maintenance a Sign Your Drain Valve is Failing?

You’re tired of the constant hassle and expense of boiler maintenance. You fix one problem, only to have another one pop up a few months later.

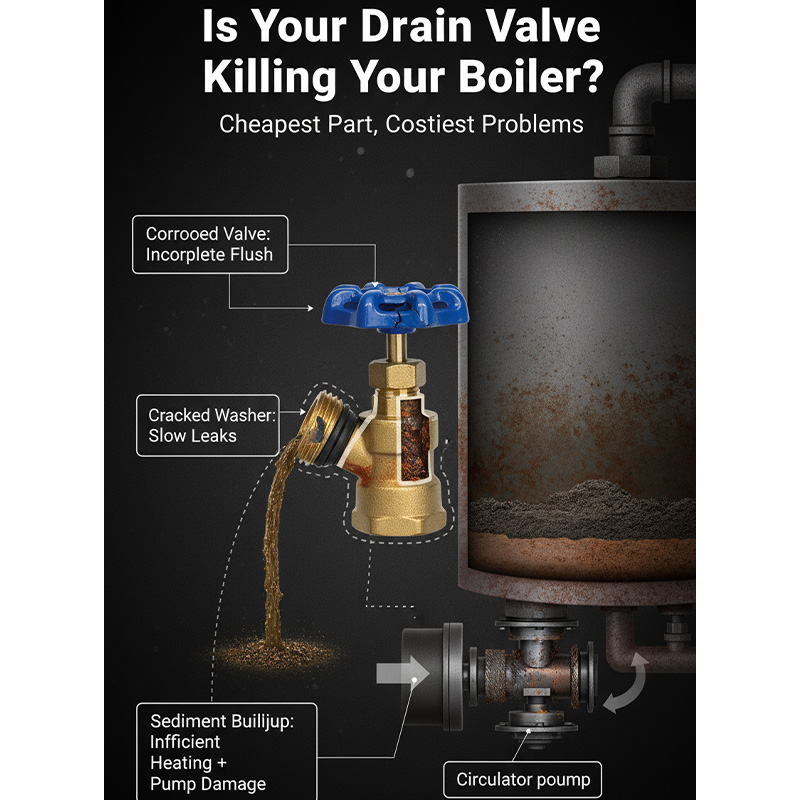

The problem might not be your boiler, but its cheapest and most neglected part: the drain valve. A failing valve causes incomplete flushes, sediment buildup, and slow leaks, which are the root causes of kettling, corrosion, and repeated system failures.

This situation reminds me of a critical lesson from my early days in the mold factory. We had a million-dollar mold that kept producing parts with cosmetic defects. We checked everything—the temperature, the pressure, the plastic itself. The real problem? A tiny, $10 water fitting on a cooling line was clogged, causing the mold to overheat in one specific spot. It’s always the small, overlooked component that causes the biggest headache. For a designer like you, Jacky, you know this principle well: a complex system is only as reliable as its weakest link.

What Makes a Drain Valve the Hidden Culprit Behind Recurring Boiler Issues?

You hear strange noises from your boiler and your heating is inefficient. You call a technician, but the problems always seem to come back, leaving you frustrated.

The drain valve is the hidden culprit because its failure is slow and silent. A cheap, corroded valve can't open fully for a proper flush, and it can't close tightly to prevent leaks, creating the perfect conditions for sludge buildup and system-wide damage.

Let’s dive deeper into the mechanics. Your boiler's health depends on an annual flush to remove mineral scale and sludge that settles at the bottom. A standard, cheap gate valve corrodes easily. The rubber washer inside hardens and cracks. As a result, when you try to open it, it might only open halfway, preventing the heavy sediment from being properly flushed out. This leftover sludge acts like an insulator, forcing your boiler to work harder and longer. It also becomes an abrasive that grinds away at the expensive circulator pump's internals. It's a classic example of a "garbage in, garbage out" failure, Jacky. If you can't get the bad stuff out of the system, the system will eventually destroy itself from the inside.

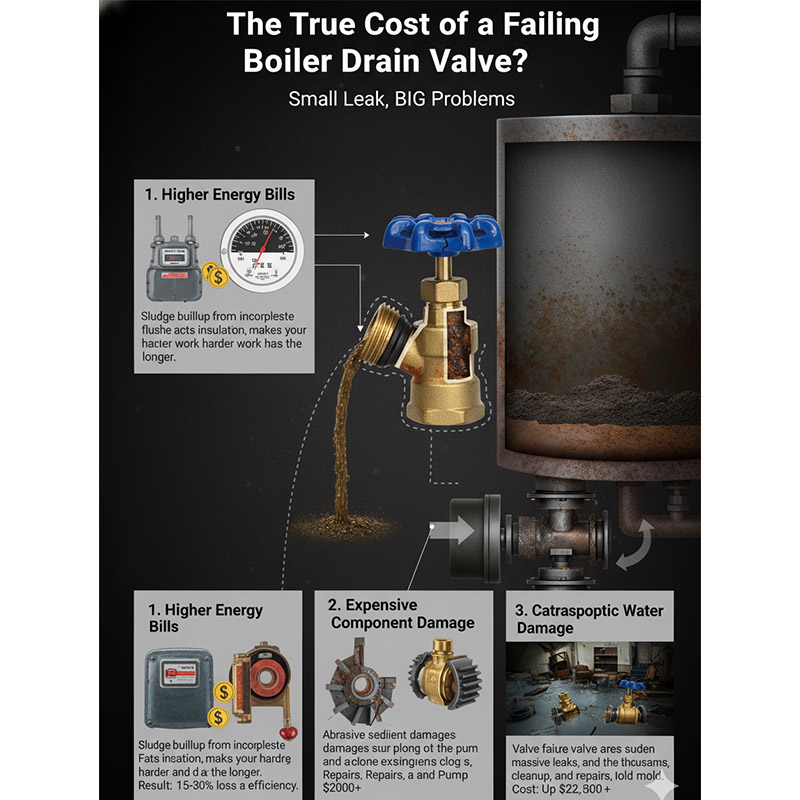

How Does a Failing Drain Valve Cost You More Than Just Leaked Water?

You see a small drip from the valve and think it's no big deal. But that tiny leak is a symptom of much more expensive problems that are already happening.

A failing valve costs you money in three ways: higher energy bills from efficiency loss, expensive damage to critical components like the heat exchanger and pump, and the risk of catastrophic water damage when the valve finally breaks completely.

This goes beyond the cost of a simple repair. It's about the total cost of ownership of a single, poorly designed component. Think about it in terms of a mold design. If you use a cheap, soft steel for a mold core to save a few hundred dollars, the eventual cost of repair, downtime, and scrapped parts will be thousands of dollars. The drain valve is no different. The gradual buildup of sediment forces your boiler to burn more fuel to heat the water, directly increasing your energy bills. That abrasive sludge wears out the circulator pump bearings and can cause hotspots on the heat exchanger, leading to premature failure. And finally, that slow drip can one day become a full-on burst, causing thousands in water damage.

The Financial Impact of a Failed Valve

| Failure Mode | Direct Cost | Indirect Cost |

|---|---|---|

| Incomplete Flush | Increased fuel/energy consumption. | Premature failure of heat exchanger and pumps. |

| Slow Leak (Drip) | Wasted water. | Potential for mold growth and minor water damage. |

| Catastrophic Failure | Cost of emergency plumber and new valve. | Major water damage to floors, walls, and structure. |

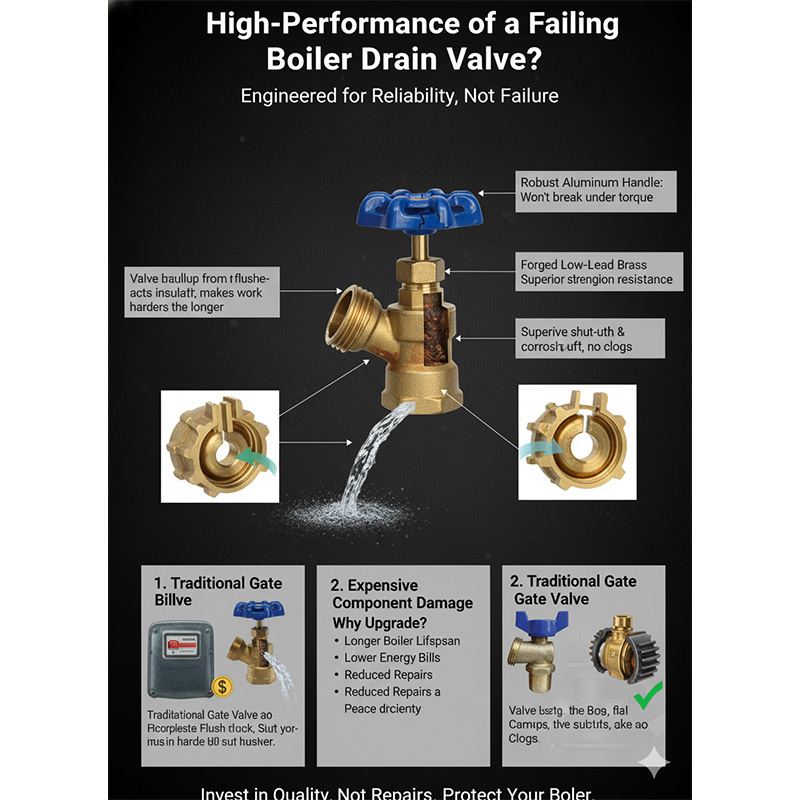

What Should You Look for in a High-Performance Boiler Drain Beyond the Basics?

You are ready to solve this problem for good, but when you look at valves, they all seem the same. How do you tell a reliable part from another future failure?

Look beyond the price tag and focus on the engineering. A high-performance drain features a forged low-lead brass body, a quarter-turn ball valve design for a positive seal, a full-bore opening for maximum flow, and a robust handle that won't break under torque.

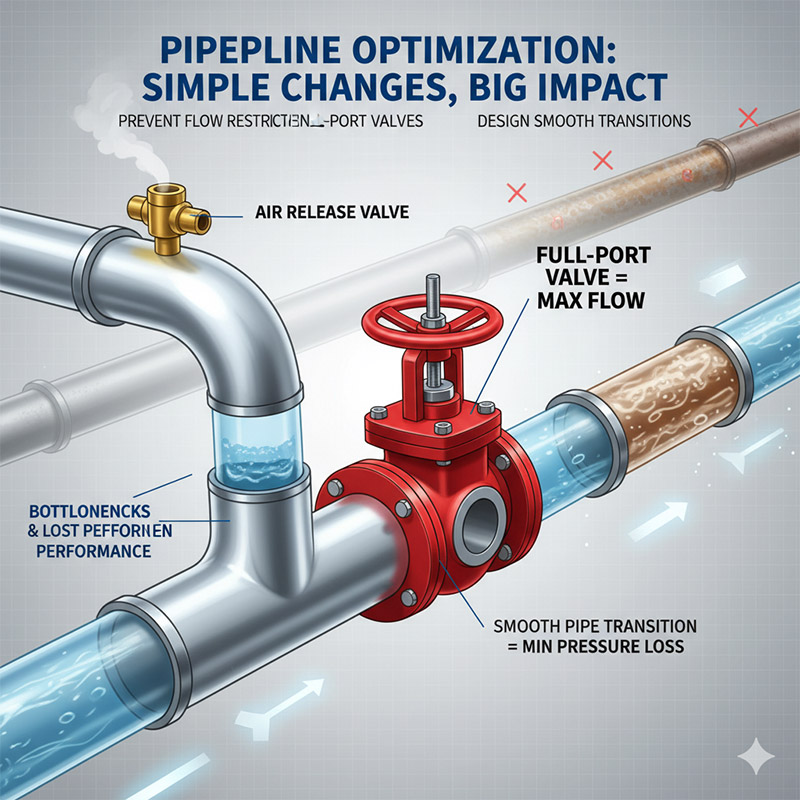

As a product designer, Jacky, you know that product excellence is found in the details of its design and material selection. The same is true here. A traditional drain often uses a multi-turn gate valve. You have to turn it multiple times, and the gate mechanism can easily get clogged with debris and fail to close properly. A quarter-turn ball valve is a far superior design. A simple 90-degree turn of the handle moves a solid ball with a hole through it, providing a clear flow path when open and a guaranteed seal when closed. The "full-bore" or "full-port" design means the hole in the ball is the same size as the pipe, so there are no restrictions during a flush. These aren't just features; they are deliberate design choices made to eliminate common failure points.

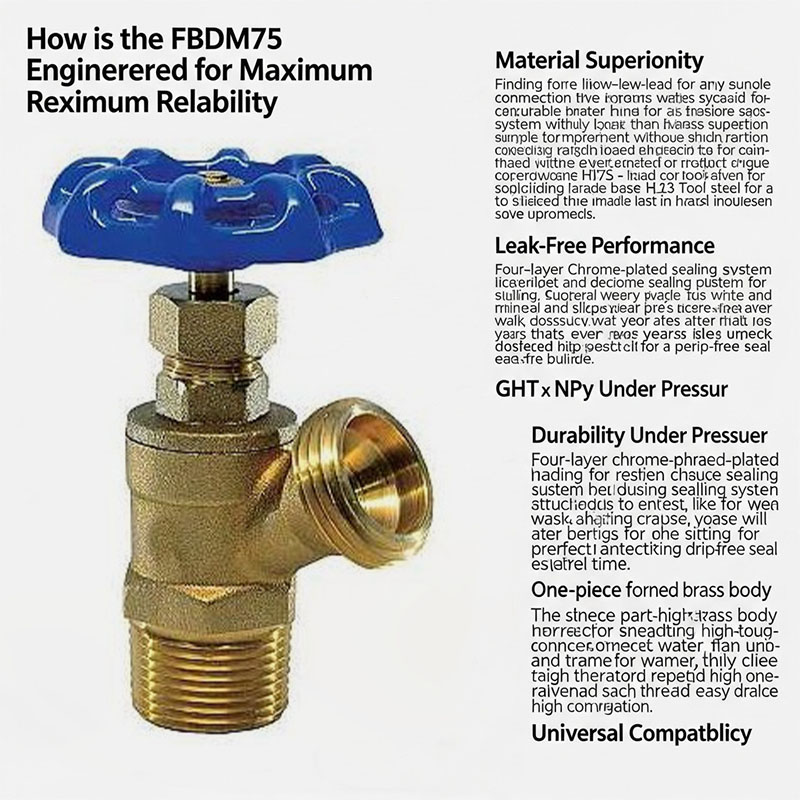

How is the FBDM75 Boiler Drain Valve Engineered for Maximum Reliability?

Finding a valve with all the right features seems difficult. You want a single product that combines superior materials, design, and durability without any guesswork.

The FBDM75 is engineered specifically to solve these problems. It uses a superior low-lead forged brass body, a four-layer chrome-plated sealing system for a leak-proof guarantee, a robust one-piece body, and universal threads for easy installation.

When I was sourcing parts for my CNC trading company, I learned to appreciate components that were designed without compromise. That is what I see in the FBDM75. Let's break down its features from an engineer's perspective:

Material Superiority

The body is made from low-lead brass, which is critical for any connection to a potable water system. More importantly for the boiler, this material is highly resistant to corrosion and dezincification, which is what causes lesser valves to seize up or become brittle over time. It's like choosing H13 tool steel for a mold instead of a softer steel—it's made to last in a harsh environment.

Leak-Free Performance

This is the key innovation. Instead of a simple rubber washer, it uses a four-layer chrome-plated sealing system. This provides an incredibly robust and slick surface that resists wear and mineral buildup. It ensures that even after years of sitting idle, the valve will close to a perfect, drip-free seal every single time.

Durability Under Pressure

The one-piece forged brass body is incredibly strong. Forging creates a denser, more uniform grain structure than casting, making it far less likely to crack under the stress of a wrench or from water hammer. This is a part designed for repeated, high-torque use without failure.

Universal Compatibility

The GHT x NPT thread design is a simple but brilliant touch. The GHT (Garden Hose Thread) end means any standard hose connects for easy draining. The NPT (National Pipe Taper) end is the US standard for plumbing, ensuring it will thread securely into your boiler. It’s designed for the real world.

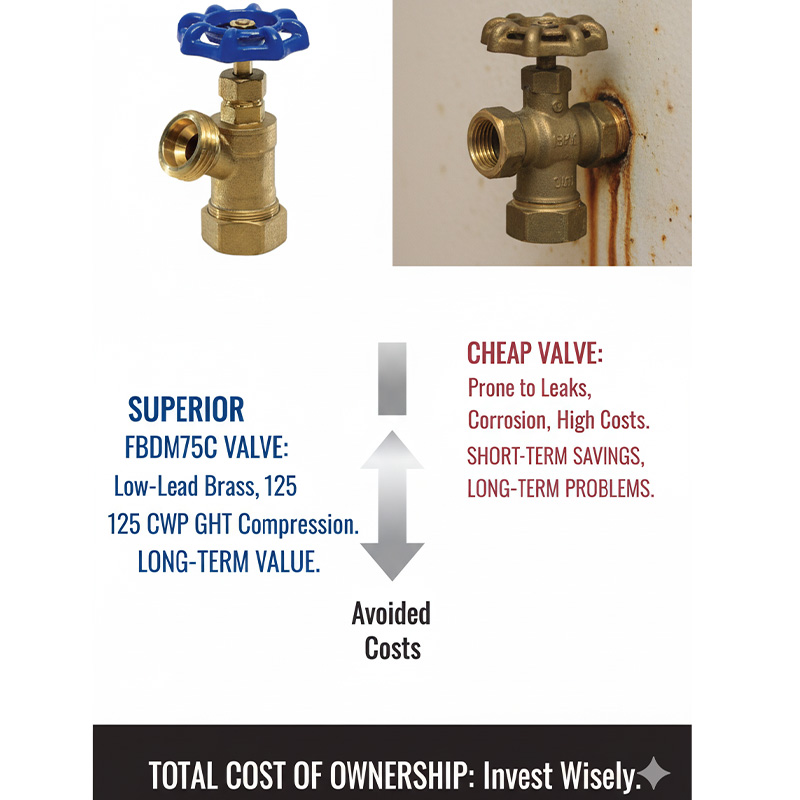

What is the Long-Term Value of a Superior Drain Valve?

It's tempting to save $15 and buy the cheaper valve. But that short-term saving sets you up for a repeat of the same problems in a few years.

The long-term value of a superior valve is measured in avoided costs. It's the money you don't spend on extra service calls, high energy bills, and replacing other expensive boiler components that are damaged by a poorly maintained system.

This is a classic Total Cost of Ownership calculation, Jacky. The purchase price of a component is only a small part of its true cost. The cheap drain valve might cost $10, but if it causes your energy bill to go up by $10 a month and leads to a $500 pump replacement in three years, its total cost is immense. The superior FBDM75 valve might cost $25, but it protects that $500 pump and keeps your energy bills low. It pays for itself many times over. In my business, I'd always choose the more expensive, high-endurance cutting tool for our CNC machines. Why? Because it lasted longer, produced a better finish, and reduced machine downtime. The initial cost was higher, but the value was far greater.

Why Should You Stop Replacing and Start Upgrading Your Boiler Drain?

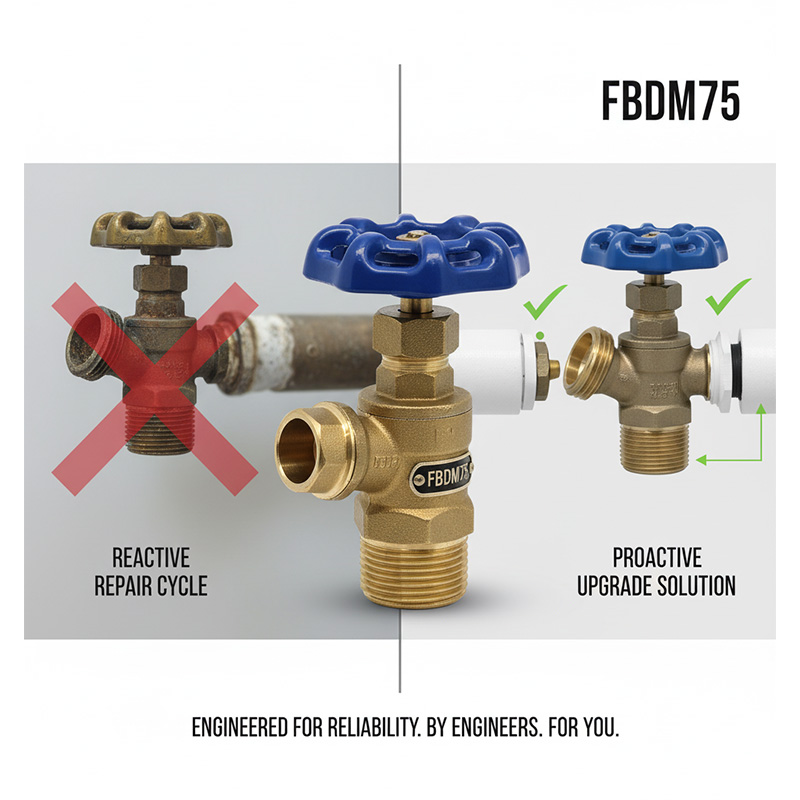

You're caught in a reactive cycle of repair. When a part fails, you replace it. But this approach guarantees that you will face the same problem again.

You need to shift from a "replace" mindset to an "upgrade" mindset. Replacing a failed part with an identical cheap part just resets the clock on the next failure. Upgrading to a superior component breaks the cycle by permanently engineering the weak link out of the system.

As an engineer, Jacky, your job is to create better, more reliable products. You should apply that same logic to your own home. When a component fails due to a clear design flaw, you wouldn't just replace it with an identical one in your own product designs; you would conduct a root cause analysis and specify a better component. This is no different. The standard boiler drain is a known failure point. Recognizing this and choosing a product specifically engineered to overcome these failures—like the FBDM75—is the most logical, efficient, and satisfying solution. It's the difference between being a parts-swapper and being a problem-solver. You are choosing to improve the system, not just patch it.

Conclusion

Your boiler's reliability depends on its weakest part. Upgrading your drain valve is a small, proactive investment that eliminates a common point of failure, saving you money and ensuring lasting peace of mind.