What Do Global Buyers Really Demand from Valve and Fitting Suppliers Today?

You source parts globally, but face inconsistent quality and unreliable delivery. This uncertainty puts your project timelines and your company's reputation at constant risk.

Buyers today demand more than just a low price. They look for proven reliability through verifiable data, a resilient supply chain they can trust, and a true expert partner.

I had a discussion with a new client a few months ago. He was a lead engineer for a large water treatment company in Germany. For years, his company's policy was to source from the lowest-cost supplier who could meet the basic specifications. Then, a massive project was derailed by a shipment of fittings that had hairline cracks. The supplier was on the other side of the world, communication was difficult, and the whole project ground to a halt for six weeks. He told me, "Mike, that disaster cost us more than we'd saved in ten years of buying cheap parts. We're not buying products anymore; we are buying certainty." His story perfectly captures the shift I'm seeing everywhere. The global market isn't just about price anymore. It's about trust, reliability, and removing risk.

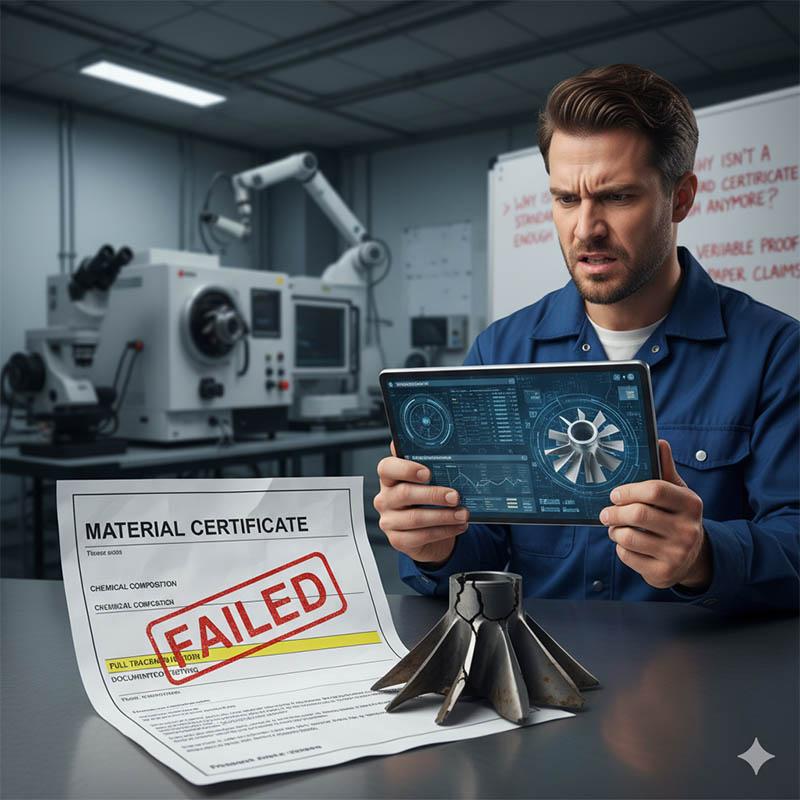

Why Isn't a Standard Material Certificate Enough Anymore?

A component that meets the spec on paper fails prematurely in the field. You are left questioning the supplier's true quality, feeling frustrated by the material's poor performance.

A certificate proves what a part should be. Sophisticated buyers now want verifiable proof of what it is, demanding full traceability and documented testing for every single component they purchase.

For decades, the Mill Test Report (MTR) was the gold standard. It’s a document from the steel mill certifying that the metal meets a certain standard, like ASTM A479 for 316 stainless steel. But experienced designers like you, Jacky, know there's a gap between that certification and the finished part in your hand. What happened between the mill and the final product? Was the material stored properly? Was there a mix-up on the factory floor? A piece of paper can't answer those questions. That's why savvy buyers now demand more. They want proof of a continuous chain of custody. They want to see Positive Material Identification (PMI) results from when the material arrived at the factory. And they want to see the hydrostatic or pneumatic test results for the specific valve they are holding, not just one from a random batch. This move from "paper quality" to "proven quality" is the new baseline.

From Paper Assurance to Proven Reality

-

### The Traceability Chain True reliability comes from an unbroken chain of data. Buyers want to see a clear line from the original material heat number on the MTR to the unique serial number marked on their finished part.

-

### The Power of 100% Testing Batch testing is a cost-saving measure that introduces risk. Testing every single valve ensures that a hidden flaw in one part doesn't bring down your entire system.

| Standard Assurance (The Old Way) | Modern Assurance (The New Standard) |

|---|---|

| Provides Mill Test Report (MTR) only. | Provides MTR and in-house PMI results. |

| Batch tests a small sample of parts. | Pressure tests 100% of finished valves. |

| Relies on paperwork for proof. | Provides serialized parts with unique test reports. |

How Can You Trust a Supply Chain You Can't See?

Your project is stalled because a supplier's supplier had a problem. You are left in the dark, unable to get clear answers, and your critical production deadlines are slipping.

You can't. That is why buyers are now choosing partners with vertically integrated or tightly controlled manufacturing. They need visibility into the entire process to trust the timeline and the quality.

Recent world events have taught us all a painful lesson about fragile supply chains. A problem in one small factory in one country can create a ripple effect that shuts down production thousands of miles away. Buyers are tired of this uncertainty. They’ve been burned by suppliers who are just middlemen, reselling parts from a dozen different smaller factories. When a problem occurs, nobody takes responsibility. To counter this, buyers are now actively seeking partners who control their own destiny. They want to work with factories that handle everything from raw material verification to final testing under one roof or in a very tightly managed system. This gives you, the designer, a single point of contact and a single source of truth. You know that if there's a question, you'll get a real answer, not an excuse. It transforms the supply chain from a source of risk into a source of strength.

Building a Supply Chain You Can Count On

-

### The Weakness of Anonymous Sourcing When a supplier is just a trader, they have little control over the quality or production schedule of the actual manufacturer. They are passing the risk on to you.

-

### The Strength of Controlled Manufacturing A manufacturer who controls their own process can provide accurate lead times, consistent quality, and immediate answers when challenges arise.

| Fragile Supply Chain | Resilient Supply Chain |

|---|---|

| Opaque; many unknown sub-suppliers. | Transparent; clear line of sight to manufacturing. |

| Communication is slow and indirect. | Communication is direct and fast. |

| Quality is inconsistent between batches. | Quality is consistent due to single process control. |

| High risk of unexpected delays. | Predictable and reliable lead times. |

Is Your Supplier Just a Vendor or a True Partner?

You have a complex design challenge, but your supplier just sends you a catalog. They lack the engineering insight to help, leaving you to solve the difficult problems alone.

A vendor sells parts; a partner solves problems. Global buyers now actively seek suppliers with deep engineering expertise who act as an extension of their own team, offering valuable design and material advice.

This is perhaps the most important shift of all. In the old model, the relationship was purely transactional. You sent a purchase order for a part number, and the supplier shipped a box. Today, the products and systems we are building are far too complex for that model. As a product designer, Jacky, you are an expert in your field, but you can't be an expert in everything. You need a valve supplier who is also a world-class expert in fluid dynamics, material science, and high-volume manufacturing. You need someone you can call and say, "I have this corrosive media at this temperature and pressure, what do you recommend?" A true partner will engage in that conversation. They will provide suggestions based on real-world experience, potentially offering a solution that is more reliable or cost-effective than what you had originally planned. This collaborative approach, known as Design for Manufacturability (DFM), is what turns a simple supply arrangement into a powerful strategic partnership.

Moving from Transaction to Partnership

-

### From Order Taker to Problem Solver A partner proactively seeks to understand your challenges. They ask "why" to ensure the product they provide is the best possible solution, not just the one you asked for.

-

### Collaborative Design for Success By working together early in the design process, a partner can help you avoid costly mistakes, optimize performance, and reduce lead times.

| The Vendor Transaction | The Partner Relationship |

|---|---|

| Responds to RFQs with price lists. | Engages in technical discovery calls. |

| Provides a catalog of standard parts. | Offers custom solutions and material advice. |

| Relationship ends at shipment. | Provides ongoing support and expertise. |

| Solves their problem (making a sale). | Solves your problem (making your project succeed). |

Conclusion

Global buyers now seek more than just parts. They demand verifiable quality, a resilient and transparent supply chain, and a supplier who serves as a true expert engineering partner.