How Can You Recharge Your Car AC Like a Pro with a Gauge Hose?

Your car's A/C is blowing warm, and you're sweating the repair bill. Adding refrigerant blindly with a cheap kit is a huge gamble that could wreck your car.

The secret to a pro-level recharge is using a charging hose with an integrated pressure gauge. This simple tool lets you see the system's pressure in real-time, preventing dangerous overcharging and ensuring you add the perfect amount for ice-cold air.

I learned early in my manufacturing career that you can't control what you can't measure. Trying to inject molten plastic into a mold without a pressure sensor is asking for disaster—you'll either underfill the part or blow out the tool. An A/C gauge hose is that pressure sensor. It's the one simple device that transforms a wild guess into a controlled, repeatable process. For a designer like you, Jacky, this isn't just a tool; it's the essential feedback loop that makes a complex system understandable and manageable.

What is the “Just-Go-for-It” Mistake That Can Cost You a Compressor?

Your AC is weak, so you grab a DIY can. The instructions seem simple, but this impulse can lead to a catastrophic failure that costs thousands to fix.

The biggest mistake is "blind charging" without a gauge. This makes it incredibly easy to overcharge the system, creating extreme pressure that destroys the A/C compressor—the heart of the system—and contaminates the lines with metal shavings.

System Condition vs. Compressor Risk

| System State | Low-Side Pressure | Compressor Risk | Result |

|---|---|---|---|

| Undercharged | Too Low | Runs constantly or cycles rapidly, causing premature wear. | Warm Air |

| Correctly Charged | Correct Range | Operates as designed, with normal cycling. | Cold Air |

| Overcharged | Dangerously High | Risk of "liquid slugging," which leads to catastrophic failure. | Poor Cooling & Destruction |

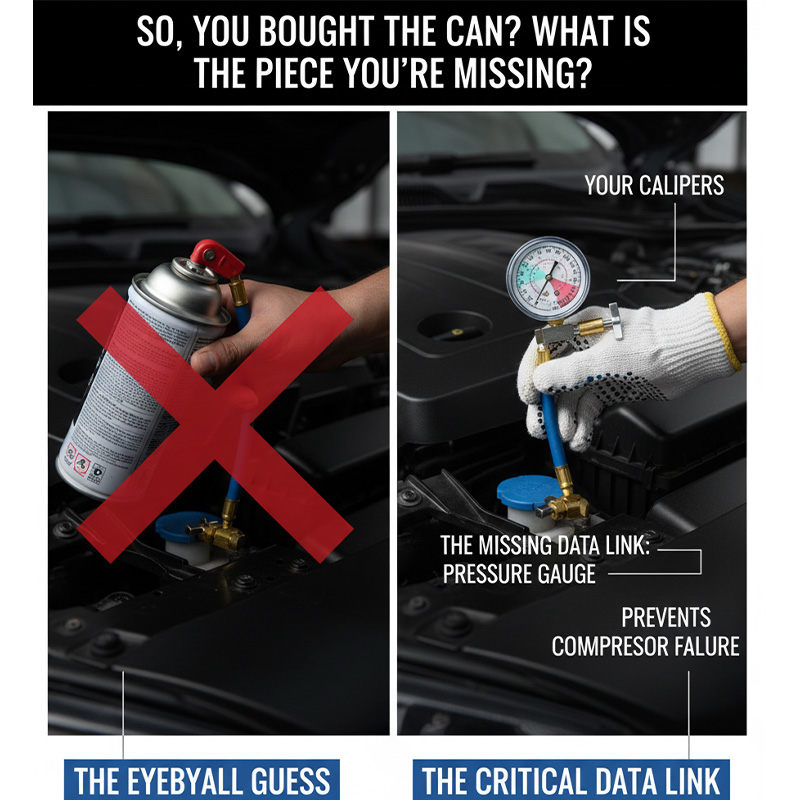

So, You Bought the Can? What is the Piece You’re Missing?

You have the refrigerant can, ready to go. But that simple trigger dispenser it came with is setting you up for failure by hiding the most important information.

You are missing the pressure gauge. A basic trigger hose offers zero visibility into your A/C system's pressure. You are working completely blind, with no way of knowing if the system is truly low, already full, or dangerously over-pressurized.

Think about it this way. In your work, Jacky, would you ever approve a critical dimension on a part just by eyeballing it? Of course not. You'd grab a set of calipers. The gauge on an A/C hose is your set of calipers. The cheap trigger hose is the eyeball guess. It lets you inject refrigerant, but it doesn't give you the feedback needed to do it correctly. It's a one-way tool in a process that demands a feedback loop. When I started my CNC business, I quickly learned that machines without real-time load monitoring were far more likely to have costly tool crashes. The load meter provided the data to prevent disaster. The gauge on your A/C hose does the same thing. It is the missing data link that makes the job possible to do right.

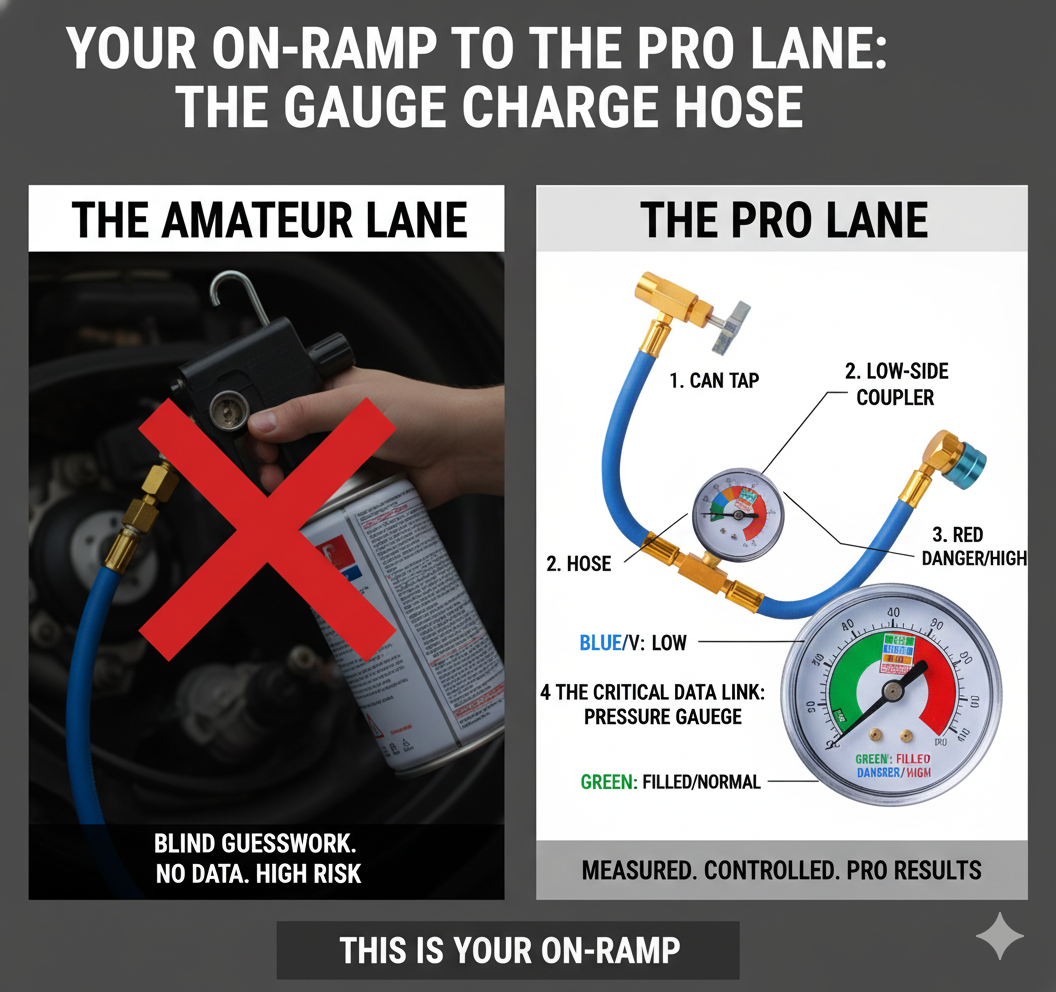

What is Your On-Ramp to the Pro Lane: The Gauge Charge Hose?

You want the satisfaction of a DIY fix but the results of a pro repair. The gap seems huge, but it can be closed with one inexpensive tool.

The gauge charge hose is your on-ramp. This single device integrates the can tap, the hose, the low-side quick coupler, and the all-important pressure gauge. It transforms the A/C recharge from a blind gamble into a measured, visible, and controlled procedure.

The beauty of this tool is in its user-centered design, something you know all about, Jacky. It takes a complex system and makes it easy to read. The gauge dial isn't just numbers; it's often color-coded. The "V" or blue zone for "low/vaccum," the green for "filled/normal," and the red for "alert/danger." This visual shortcut instantly tells you the system's status. It’s a perfect "go/no-go" gauge for a specific task. The tool is designed with a clear purpose: to allow a user with minimal training to perform a sensitive task safely. It’s an elegant piece of functional design that empowers you to work on your own car with the confidence of a professional, all because it provides one critical piece of information clearly and simply.

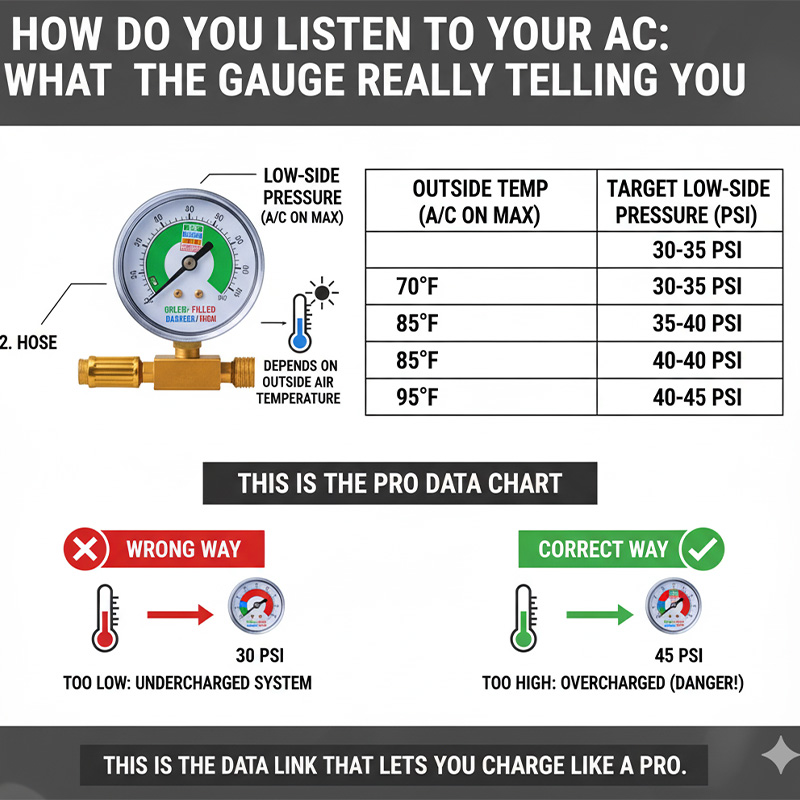

How Do You Listen to Your AC: What is the Gauge Really Telling You?

You've connected the hose and the needle is moving, but what does it all mean? A number without context is useless and can lead to a bad charge.

With the A/C on max and the engine running, the gauge shows the low-side pressure. A correct reading is not a single number but a range (often 25-45 PSI) that depends directly on the outside air temperature. This is the true sign of a healthy system.

Think of it like tuning an engine; the parameters change based on conditions. The same is true for your A/C. The system's pressure naturally increases as the outside air gets hotter. This is because the refrigerant has to work harder to shed heat in the condenser. Trying to charge to 30 PSI on a 95°F day will leave you undercharged, while charging to 45 PSI on a 70°F day will overcharge you. This is where you go from amateur to pro. You're no longer just filling until the can is empty; you're charging to a specific target based on environmental data. As a designer, Jacky, you work with data tables and tolerance charts every day. This is no different. You're simply using a data chart to hit the correct tolerance for your A/C system's performance.

Ambient Temp vs. Target Low-Side Pressure (Example)

| Outside Air Temp | Target Pressure Range (PSI) | Gauge Reading |

|---|---|---|

| 70°F (21°C) | 25 - 35 PSI | Lower Green Zone |

| 80°F (27°C) | 35 - 40 PSI | Mid Green Zone |

| 90°F (32°C) | 40 - 45 PSI | Upper Green Zone |

| 100°F (38°C) | 45 - 55 PSI | High Green/Yellow Zone |

What is The “Aha!” Moment: Feeling the Perfect Charge Click Into Place?

You are carefully adding refrigerant, watching the needle. How do you know exactly when to stop? The fear of adding too much or too little is real.

The "Aha!" moment is a combination of three things: the gauge needle is stable in the correct pressure range for the day's temperature, the air from the vents is consistently cold, and the A/C compressor is running in smooth, long cycles.

This is where you combine data with sensory feedback. You're not just looking at the gauge. You're an active part of the system. You have one hand on the refrigerant can and the other in front of the A/C vent. You add refrigerant in short bursts, then you wait and watch the needle stabilize. At the same time, you feel the air from the vent. It will get colder and colder. You also listen. An undercharged compressor clutch might click on and off rapidly. As you add refrigerant, these cycles will get longer and smoother. When the pressure is right, the air is cold, and the compressor is running smoothly—that’s it. That’s the sweet spot. It's like tuning a precision machine. You make small adjustments and observe the outputs until the entire system is operating in perfect harmony.

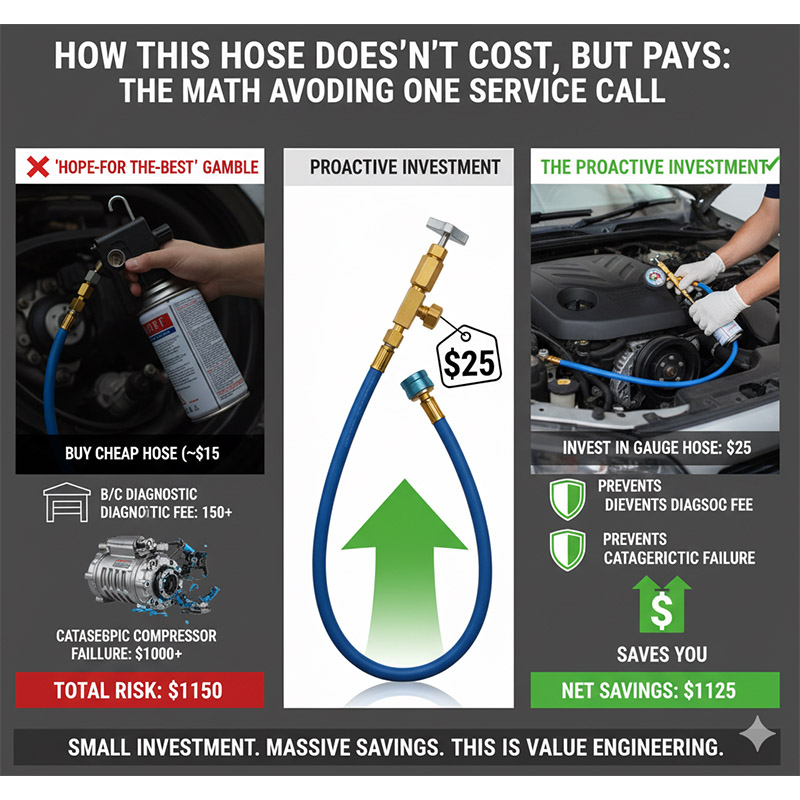

How Does This Hose Not Cost, But Pay: The Math Behind Avoiding One Service Call?

A $25 gauge hose might seem like another expense. It's tempting to just buy the basic can to save a few dollars now and hope for the best.

That $25 hose pays for itself the very first time you use it. An A/C diagnostic at a shop can be $150. A compressor replacement can exceed $1,000. The hose saves you the diagnostic fee and protects you from the catastrophic repair, making it a powerful investment.

The math is simple and undeniable. I've built my businesses on this kind of thinking: a small, smart investment in a tool or a process to prevent a massive, costly failure is always the right move. I once spent a few hundred dollars on an advanced vibration sensor for a million-dollar CNC machine. My foreman thought it was a waste of money. Six months later, it alerted us to a bearing failure before it happened, saving us a $30,000 spindle and weeks of downtime. That sensor didn't cost us money; it made us money by avoiding loss. Your gauge hose is the exact same thing on a smaller scale. For you, Jacky, this is the essence of value engineering. It's not about being cheap; it's about being smart and investing in the tools that mitigate the biggest risks for the lowest cost.

The math is simple and undeniable. I've built my businesses on this kind of thinking: a small, smart investment in a tool or a process to prevent a massive, costly failure is always the right move. I once spent a few hundred dollars on an advanced vibration sensor for a million-dollar CNC machine. My foreman thought it was a waste of money. Six months later, it alerted us to a bearing failure before it happened, saving us a $30,000 spindle and weeks of downtime. That sensor didn't cost us money; it made us money by avoiding loss. Your gauge hose is the exact same thing on a smaller scale. For you, Jacky, this is the essence of value engineering. It's not about being cheap; it's about being smart and investing in the tools that mitigate the biggest risks for the lowest cost.

Ready to Stop Sweating the Repair and Start Planning Your Next Road Trip?

Car A/C trouble is stressful. It hangs over your head, ruins your commute, and puts your travel plans on hold while you worry about a big repair bill.

Using a gauge hose empowers you to take control. This simple tool lets you safely fix the most common A/C issue yourself in under 30 minutes. It turns a major source of stress into a small, satisfying, and manageable task.

There is a huge amount of satisfaction that comes from understanding and fixing your own equipment. It's more than just saving money; it's about being self-reliant. As an engineer and designer, Jacky, you live in a world of solving problems. This is just a small-scale version of that. You identify the problem (warm air), you acquire the right tool (a gauge hose), you gather the data (pressure reading), and you implement the solution (add refrigerant to the correct level). The result is not just a cold car, but the confidence that comes from mastering a system. So, stop worrying about the heat and the repair shop. Take on this small project, get it done right, and get back to planning where the open road will take you next.

There is a huge amount of satisfaction that comes from understanding and fixing your own equipment. It's more than just saving money; it's about being self-reliant. As an engineer and designer, Jacky, you live in a world of solving problems. This is just a small-scale version of that. You identify the problem (warm air), you acquire the right tool (a gauge hose), you gather the data (pressure reading), and you implement the solution (add refrigerant to the correct level). The result is not just a cold car, but the confidence that comes from mastering a system. So, stop worrying about the heat and the repair shop. Take on this small project, get it done right, and get back to planning where the open road will take you next.

Conclusion

Stop guessing with your car's A/C. A simple gauge hose is the non-negotiable tool for a safe and effective DIY recharge, giving you professional results and saving you a fortune.