How Do We Keep Every Valve and Fitting Up to Standard?

Your design is perfect, but the physical parts you receive are inconsistent. This causes frustrating assembly delays and puts your entire project and reputation at risk.

We guarantee standards by embedding a rigorous quality system into every stage. It begins with proactive design collaboration, continues with real-time process control, and ends with data-driven final verification.

I remember visiting a potential client's assembly line years ago. They were having trouble with fittings from their current supplier. On a table was a large bin of rejected parts—dozens of them. The assembly technician told me, "Some fit, some don't." I picked up two identical-looking fittings from the 'good' bin and measured them with my own calipers. They were visibly different. Their supplier's "standard" was a range so wide it was almost meaningless. That visit burned a lesson into my mind: a standard isn't just a number on a drawing. It is a promise of absolute consistency, part after part, batch after batch. We built our entire quality system around delivering on that promise.

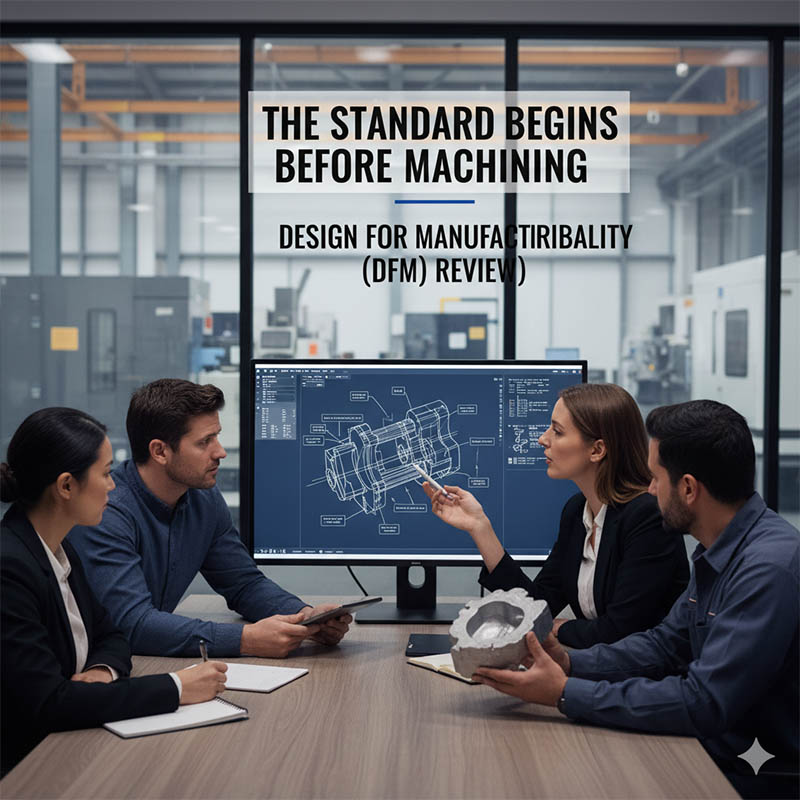

Does the Standard Begin Before Machining Starts?

You send a perfect drawing, but the final part has issues. The supplier just followed instructions without truly understanding the design's intent, creating manufacturability problems you didn't foresee.

Yes, the standard is set long before any metal is cut. It begins with a deep, collaborative Design for Manufacturability (DFM) review to ensure your design's intent is perfectly preserved.

The most critical moment for setting a standard happens at the very beginning. A drawing can tell us what to make, but a conversation with you, the designer, tells us why. Is that tight tolerance for a bearing press-fit or for an O-ring seal? Does that surface finish need to be smooth for fluid flow or for aesthetics? This is the purpose of our Design for Manufacturability (DFM) process. We don't just take your CAD file and load it into a machine. We sit down with it and analyze every feature. We look for potential challenges, like sharp internal corners that are difficult to machine, or wall thicknesses that might warp during heat treatment. By having this discussion with you, Jacky, before we start, we can make minor adjustments that have a major impact on the quality, consistency, and even the cost of the final part.

Setting the Blueprint for Success

-

### Translating Design Intent We work to understand the function of every feature. This allows us to apply the right manufacturing techniques to achieve your performance goals, not just dimensional accuracy.

-

### Proactive Problem Solving Our DFM review identifies potential manufacturing issues early. This prevents costly surprises and delays down the line, ensuring a smooth path from design to production.

| Standard "Order Taking" | Collaborative DFM Partnership |

|---|---|

| Accepts drawing as-is. | Analyzes drawing for intent. |

| Issues are found during production. | Issues are prevented before production. |

| Focus is on dimensions only. | Focus is on function and performance. |

| Risk lies with the designer. | Risk is shared and mitigated together. |

How Do You Control Quality in Real-Time?

A perfect first-off part gives you confidence, but the last part in the batch fails. This inconsistency forces you to waste your own valuable time inspecting everything.

We use strict in-process quality control (IPQC). Our machine operators are empowered with calibrated tools to check parts at regular intervals, catching any potential deviation the moment it occurs.

A standard that is only checked at the end of a production run is not a standard at all; it’s a gamble. Quality must be controlled in real-time. Our process for this is called In-Process Quality Control, or IPQC. It starts with a "First-Off Inspection." After setting up a new job, the operator machines a single part. That part is then taken to our quality lab and fully inspected against the drawing. The machine does not run the full batch until that first part gets a 100% pass. But it doesn't stop there. Our operators are trained and equipped to be the first line of defense for quality. At their workstation, they have a set of calibrated gauges and micrometers. Every few parts, they pull one from the machine and check its critical dimensions, ensuring the process remains perfectly stable from the first part to the last.

Building Quality into the Process

-

### First-Article Inspection (FAI) This is our gatekeeper. No mass production begins until the first part is proven to be a perfect match for your design, guaranteeing the machine setup is correct.

-

### Operator Empowerment We treat our operators as craftsmen. They are responsible and empowered to perform regular checks, stopping the line if they see even the slightest drift from the nominal specification.

| Common Approach (End-of-Line Check) | Our Approach (In-Process Control) |

|---|---|

| Finds defects after a full batch is made. | Prevents defects from ever multiplying. |

| Leads to high scrap rates and rework. | Leads to high consistency and efficiency. |

| Operators just run machines. | Operators own the quality of their work. |

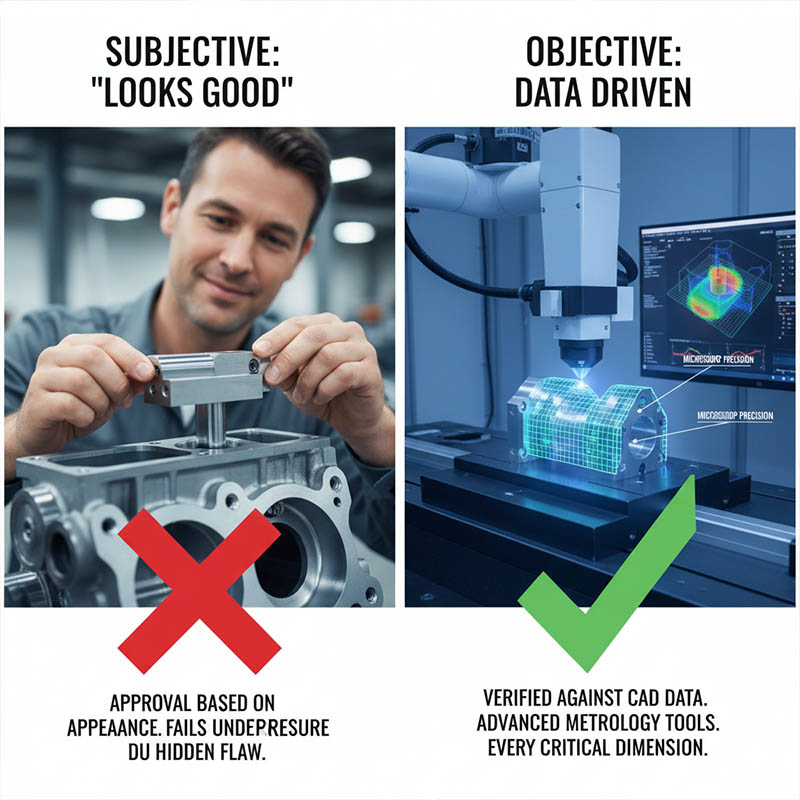

Is 'Looks Good' a Real Inspection Standard?

A part looks and fits perfectly, so you approve it. But it fails under pressure due to a hidden dimensional flaw a simple visual check could never catch.

No. "Looks good" is not a standard; objective data is. Our final inspection uses advanced metrology tools to verify every critical dimension against your original CAD data with microscopic precision.

The final step is to prove that everything we've done is correct. This happens in our dedicated quality lab, and it goes far beyond what the human eye can see. Our most powerful tool here is the Coordinate Measuring Machine, or CMM. Think of it as a hyper-accurate robot. It uses a sensitive probe to touch hundreds or even thousands of points on the part's surface. It then compares this real-world "point cloud" directly against your original 3D CAD model. A CMM can detect deviations as small as a few microns (thousandths of a millimeter). For you, Jacky, this means you can have absolute confidence that complex geometries, hole positions, and sealing surfaces are not just "close," but dimensionally perfect. This isn't about opinion or feel; it's about generating an empirical, data-driven report that proves the part meets the standard.

Verifying the Standard with Data

-

### Beyond Calipers: CMM Inspection For complex geometries, a CMM is the only way to ensure true conformance to the design. It removes all human error and subjectivity from the final inspection process.

-

### Data-Driven Quality Reports We don't just tell you a part is good; we show you the data. A detailed inspection report accompanies our shipments, providing the ultimate proof of quality.

| Basic Inspection | Advanced Metrology |

|---|---|

| Visual Check & Calipers | CMM & Optical Comparison |

| Subjective ("It looks right.") | Objective ("The data is correct.") |

| Can miss complex geometric errors. | Catches all deviations from the CAD model. |

| Provides opinion. | Provides proof. |

Conclusion

Maintaining a standard is a system, not a single action. It's our commitment to proactive design, real-time control, and data-driven verification that ensures every part we make is perfect.