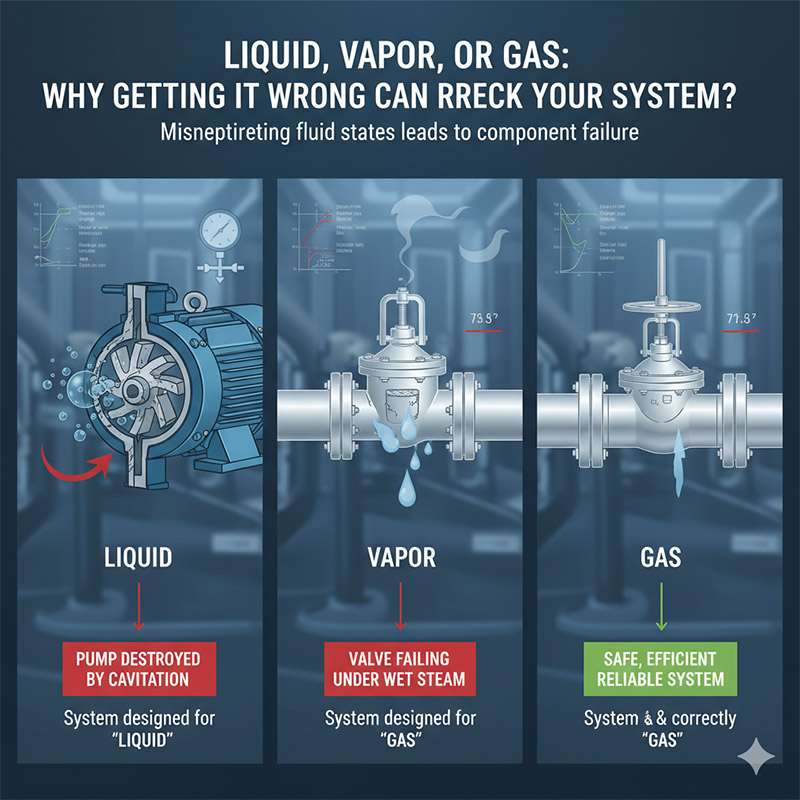

Liquid, Vapor, or Gas: Why Getting It Wrong Can Wreck Your System? You designed your system for a “liquid,” but the pump is getting destroyed by cavitation. Or you specified a valve for a “gas,” but it’s failing under wet steam. T

How Can You Avoid Costly Leaks in Your Pipeline System? A single, tiny leak can cause huge problems. It leads to product loss, safety risks, and expensive downtime, damaging your company’s reputation and bottom line. Avoiding leak

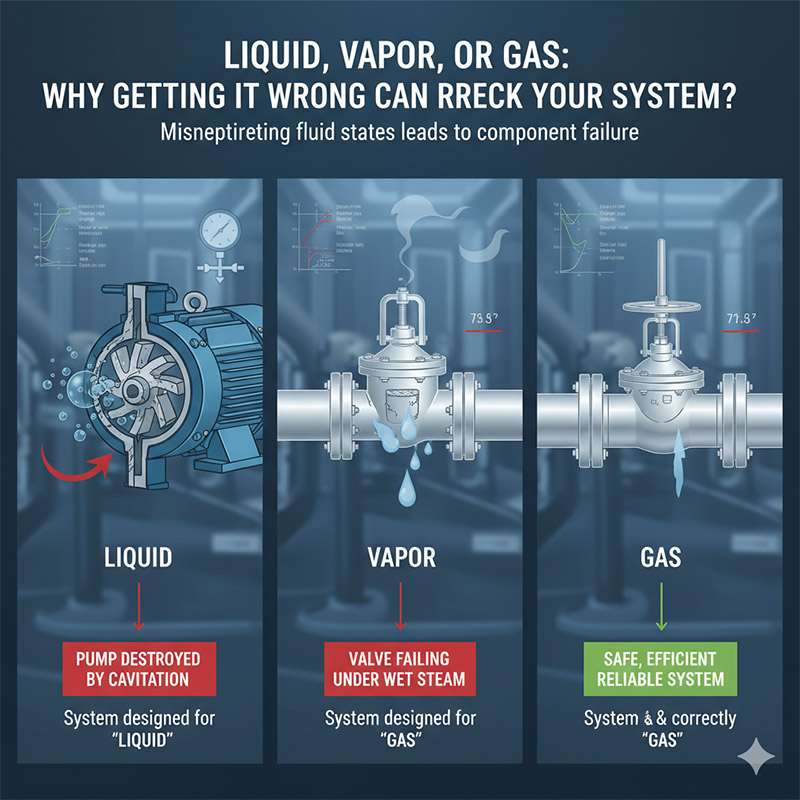

How Do Right Valves and Fittings Solve Common Piping System Problems? Your design is flawless on paper, but in the real world, it fails. Persistent leaks, unexpected corrosion, and poor flow can ruin a project and your reputation.

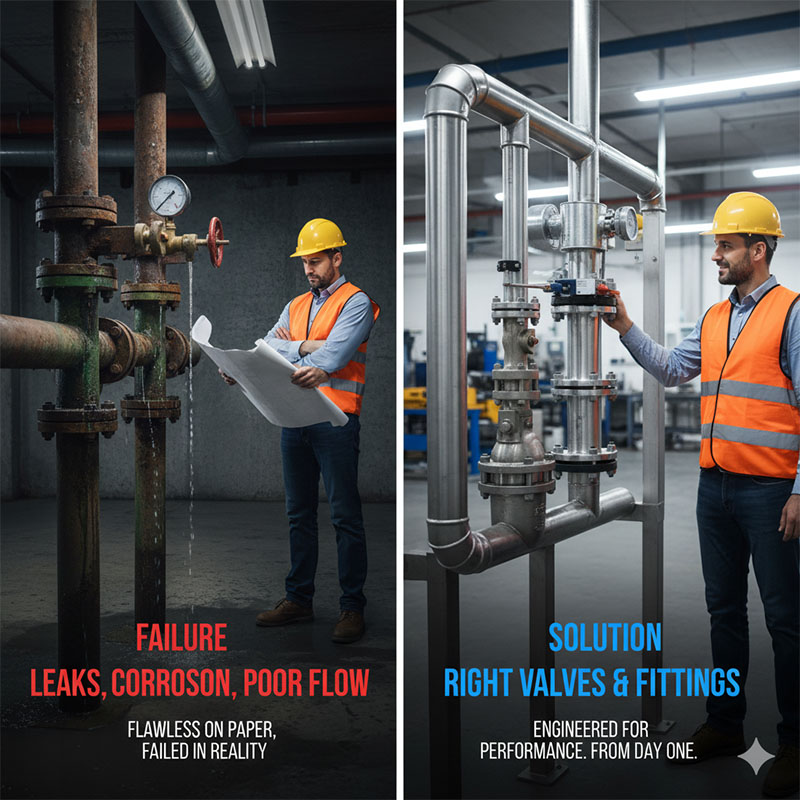

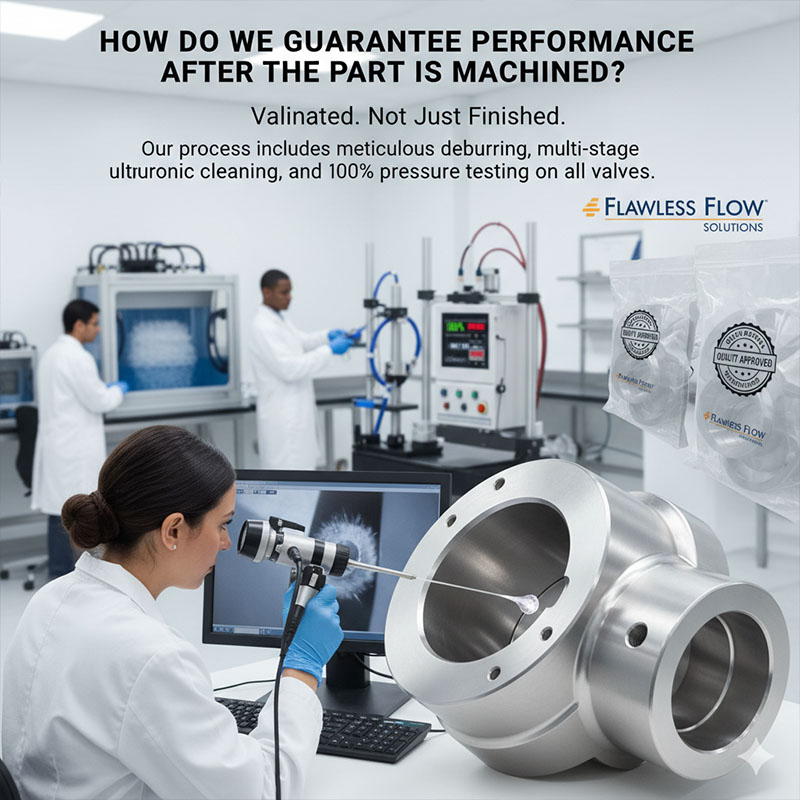

How Do We Prove Our Valves and Fittings Will Perform Flawlessly? You’ve approved the design, but will it perform under pressure? A hidden flaw in a finished part can cause a catastrophic field failure, destroying your product’s re

How Do We Guarantee Quality from Raw Material to a Finished Valve? You’ve specified a high-grade material for a critical valve. But how can you be sure the factory used that exact alloy, and not a cheaper look-alike? Our qua

How Do We Turn Raw Metal into Trusted Precision Parts? You receive a shipment of gleaming new parts, but a nagging doubt remains. You can’t see the internal quality, leaving you to hope that they perform as promised. Our factory b

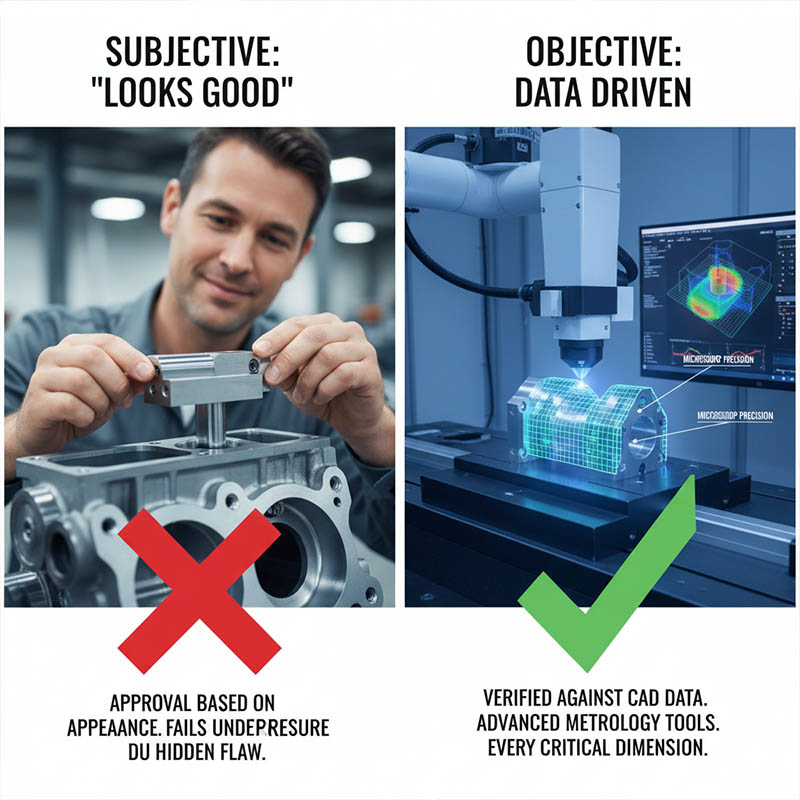

How Do We Keep Every Valve and Fitting Up to Standard? Your design is perfect, but the physical parts you receive are inconsistent. This causes frustrating assembly delays and puts your entire project and reputation at risk. We gu

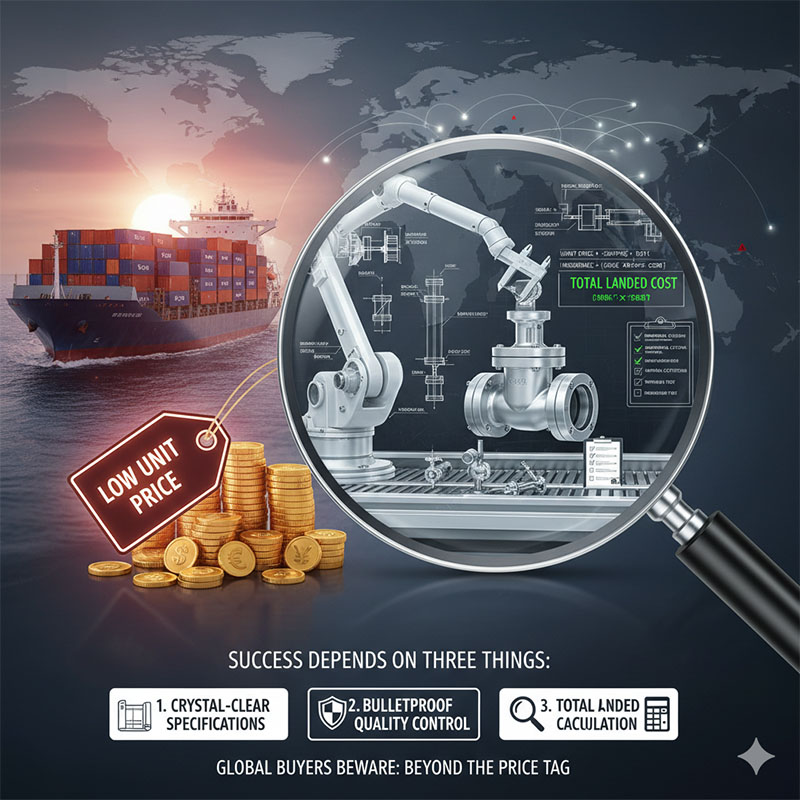

What Do Global Buyers Really Demand from Valve and Fitting Suppliers Today? You source parts globally, but face inconsistent quality and unreliable delivery. This uncertainty puts your project timelines and your company’s reputati

What Does a “Quality First” Commitment Really Mean in Manufacturing? You see “Quality First” in every supplier’s brochure, but you still worry about hidden flaws. The slogan feels empty when a single faulty component can jeopardiz

How Do We Make Every Single Valve and Fitting Count? You’ve designed a perfect system on paper. But a single, seemingly insignificant fitting fails, causing a leak that shuts everything down and puts your project weeks behind sche

Why Are High-Quality Valves More Critical Than Ever Before? You’re designing advanced systems, but component failures continue to cause setbacks. The standard valves that worked for years are now becoming a source of unreliability

What Does Quality Valve Manufacturing Really Take? You specify a quality valve, but it fails unexpectedly. Hidden manufacturing defects can undermine even the best designs, causing frustrating and costly downtime that reflects on

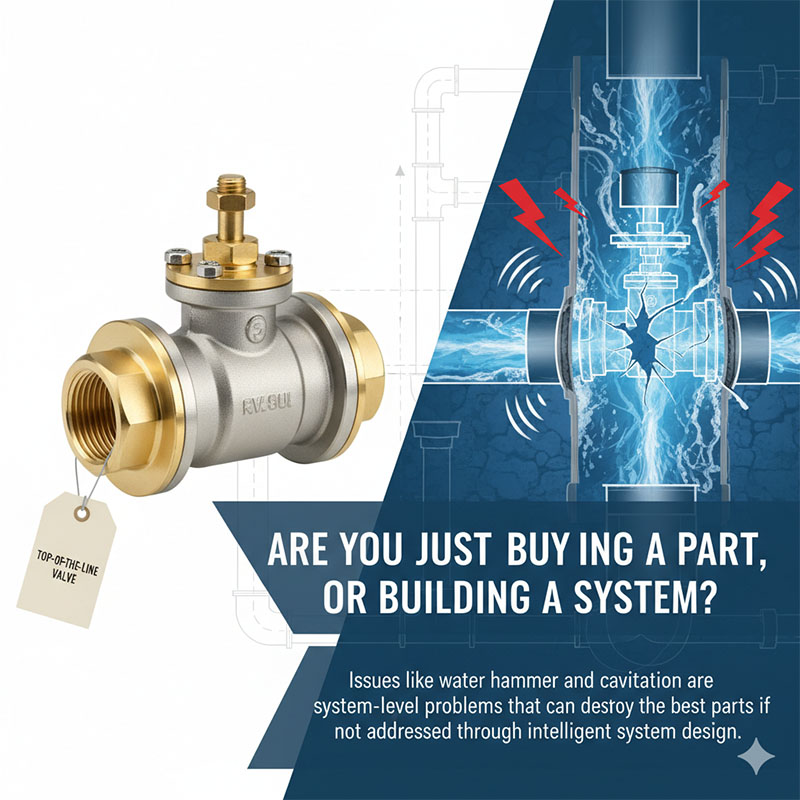

What Makes a Flow Control System Truly Robust? You meticulously design a system with quality parts. But unexpected failures, leaks, or vibration still occur, causing costly downtime and threatening your project’s reputation. A tru

How Can Custom Metal Parts Actually Save You Time and Cost? You need a specific part, but a custom solution feels too expensive. So you design around standard components, adding complexity, extra fittings, and unexpected labor cos

How Can You Fix Common Valve Issues Before They Cost You Time and Money? A simple valve failure can shut down an entire production line. It’s a small component causing a huge, expensive headache, and you are left to pick up the pi

What Should Global Buyers Know Before Sourcing Valves and Fittings from Overseas? Sourcing overseas seems cheap, but you’re worried about quality and delays. A single mistake in communication or quality can wipe out all your initi