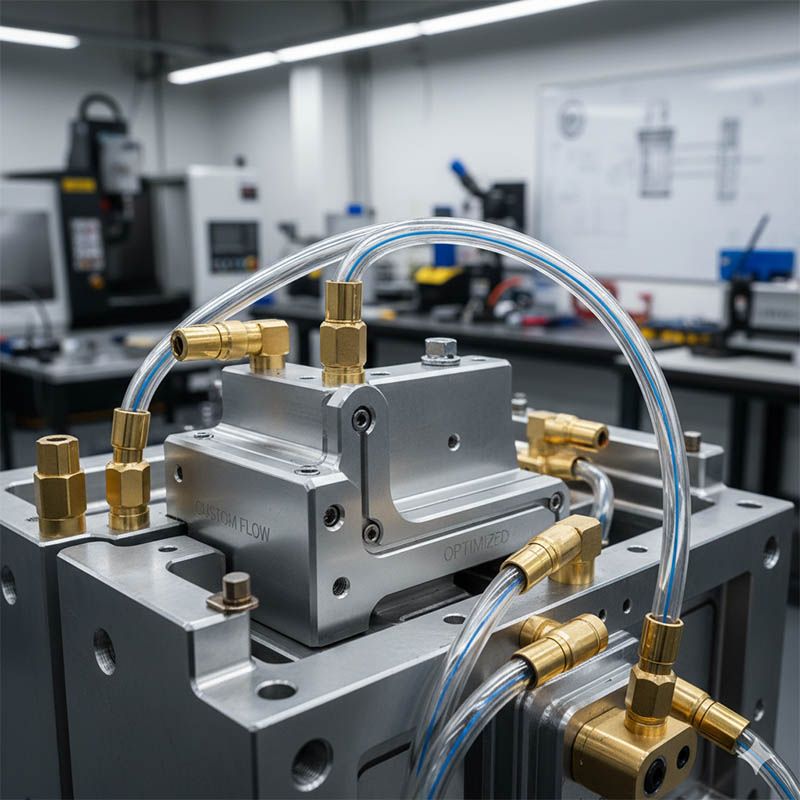

How Can You Double the Life of Your Mold's Piping Components?

Your high-performance mold is plagued by premature failures. Constant leaks from corroded or cracked piping components are causing frustrating downtime and eating into your production schedule and budget.

You can dramatically extend component life by focusing on two critical areas: selecting the right materials to prevent corrosion and correctly managing mechanical stress from vibration. These proactive steps are the secret to building a truly robust and reliable mold.

Early in my career, I visited a factory that was having a nightmare with a brand-new, expensive mold from Europe. It was constantly leaking. When I looked closer, I saw the problem immediately. The mold was designed to run hot oil for a high-temperature process, but it was plumbed entirely with standard brass fittings and cheap rubber hoses meant for cold water. The high heat was degrading the seals and the oil was slowly eating away at the components. The client had tried to "save" a few hundred dollars on the plumbing. That "saving" was costing them thousands per day in downtime and oil cleanup. It taught me a permanent lesson: the piping isn't just an accessory to the mold; it is the mold's circulatory system. And if it fails, the whole mold is dead.

Is a "One-Size-Fits-All" Material Strategy Silently Destroying Your Molds?

You're using standard brass fittings for all your cooling and hydraulic lines because it's simple and the parts are cheap. But now you're seeing green corrosion and pitting on some lines.

This common practice is a false economy. Matching your material to the fluid type and operating temperature is crucial. Using the wrong material invites chemical and galvanic corrosion, which guarantees premature failure and leaks.

As a designer, it’s easy to think of a fitting as just a fitting. But the chemistry tells a different story. If you’re just running standard city water through a mold at room temperature, brass is often a great, cost-effective choice. But the moment you start using treated water with rust inhibitors and other chemicals, or you use a temperature controller to run hot glycol or oil, everything changes. Those chemicals and temperatures can attack the zinc in the brass alloy, causing it to weaken and crumble from the inside out. This is why paying a little more for stainless steel in those critical applications isn’t an upgrade; it’s a necessity. It’s the difference between a system that lasts for years and one you’re fixing every few months.

Understanding Galvanic Corrosion

This is a silent killer for molds. When you connect two different metals (like a brass fitting to a steel mold plate) in the presence of water, you create a small battery. One metal (the less noble one, like the zinc in brass) will start to corrode to protect the other. That’s why you might see a fitting that looks fine on the outside get eaten away at the threads. You can prevent this by using materials that are close together on the galvanic scale, like using stainless steel fittings on a steel mold.

Matching Materials to the Job

There is no single "best" material, only the "right" material for the specific application. Creating a simple selection guide for your projects can save countless hours of future maintenance.

| Fluid Type | Max Temperature | Recommended Material | Why It's the Right Choice |

|---|---|---|---|

| Standard Tower Water | < 80°C (175°F) | Brass, Stainless Steel 304 | Good general performance and cost-effective. |

| Treated/Glycol Water | < 120°C (250°F) | Stainless Steel 304/316 | Resists the chemicals found in treated water. |

| High-Temp Oil | > 120°C (250°F) | Stainless Steel 316, Carbon Steel | Handles high temperatures without degradation. |

| Aggressive Fluids | Varies | Specialty Alloys, PTFE Lined | Required for specific chemical compatibility. |

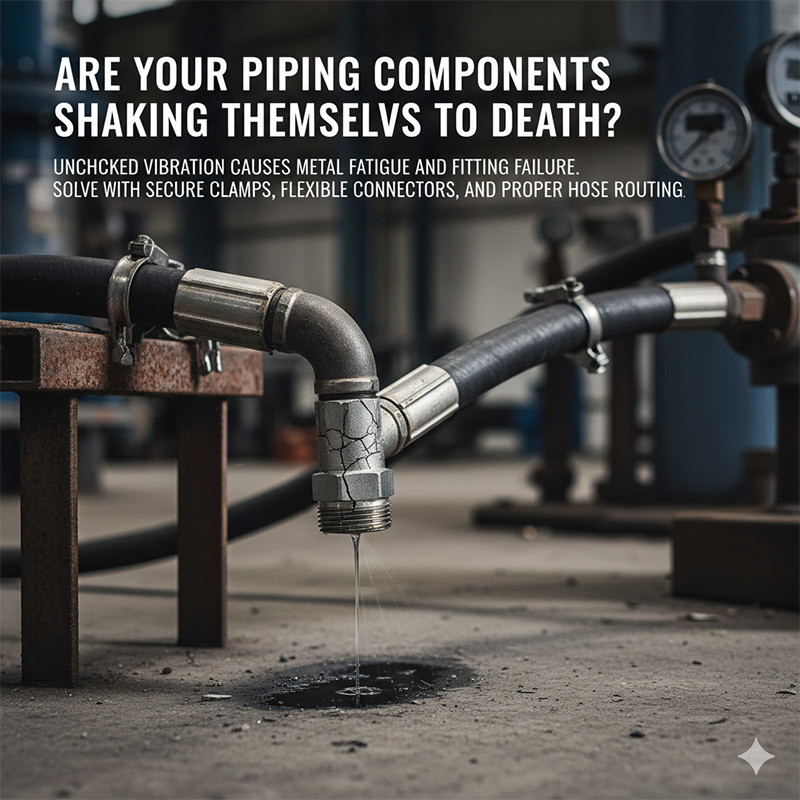

Are Your Piping Components Shaking Themselves to Death?

You have a hydraulic line that keeps failing at the connector. You replace the fitting, but the intense vibration and pressure pulses from the system just cause it to leak again.

Yes, unchecked vibration creates metal fatigue, which is a primary reason for fitting failure. You can solve this by securely clamping hoses, using flexible connectors, and ensuring proper hose routing and length.

I've seen so many mold designs where the hydraulic and water lines look like an afterthought—a spaghetti mess draped over the mold. This isn't just messy; it's dangerous. A whipping hydraulic hose under pressure carries incredible force. More commonly, the constant, tiny vibrations from the machine travel down a taut hose and concentrate all their destructive energy right at the fitting threads. It’s like hitting the fitting with a tiny hammer, millions of times, until it cracks. This is why proper clamping and hose routing isn't about looking tidy. It's about stress and energy management. You are intentionally building weak points (gentle bends in the hose) and strong points (cushioned clamps) to control the vibration and protect your connections.

The Role of Proper Clamping

Clamps are not just for organizing hoses. They are critical vibration dampers. A hose should be clamped securely to a stable part of the mold to isolate the fitting from the machine's movement. Using cushioned "P-clamps" is a best practice, as the rubber insert absorbs high-frequency vibrations before they can reach the connection point. This single, simple step can drastically reduce fatigue-related failures.

Hose Routing and Length Best Practices

The way you route a hose is just as important as the hose itself. The length needs to be just right—not too short and not too long. A hose that is pulled tight acts like a guitar string, transmitting every vibration directly to the fitting. A hose that is too long can get snagged, rub against a sharp edge, or whip around during pressure changes.

| Common Routing Mistake | The Problem It Creates | The Correct Professional Practice |

|---|---|---|

| Hose pulled taut between two points | High static tension, magnifies vibration stress. | Leave a gentle slack or S-bend to absorb movement. |

| Routing hoses against sharp corners | Abrasion can cut through the hose, causing a burst. | Use protective sleeves or route lines away from edges. |

| Long, unsupported hose runs | Hose can sag, kink, or whip violently. | Clamp hoses at regular intervals (approx. every 18-24 inches). |

| Using many 90° fittings | Creates flow restriction and turbulence. | Use bent tube adapters or hoses with sweep fittings. |

Conclusion

Proactive design choices in material selection and vibration control are direct investments in your mold's uptime. They turn your piping from a weak point into a pillar of reliability.