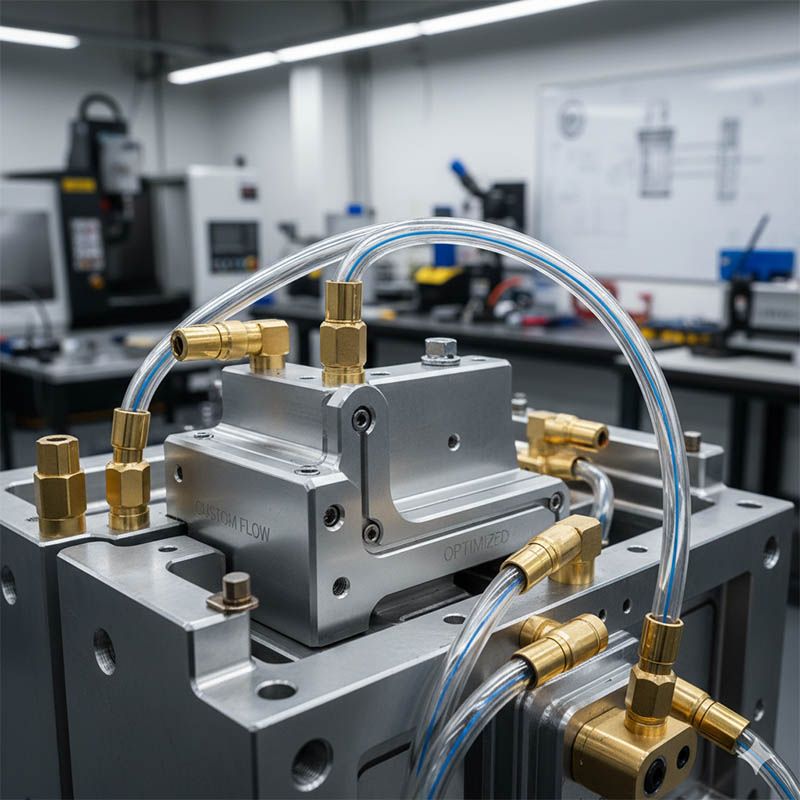

Are Your Valves and Fittings Secretly Sabotaging Your Mold?

You've spent weeks perfecting your mold design. But the humble valves and fittings are an afterthought. This mistake can lead to leaks, pressure drops, and catastrophic downtime.

Yes, poor-quality or incorrectly specified valves and fittings are a primary cause of mold failure. Choosing the right material (brass vs. stainless steel) and connection type (threaded vs. compression) for your specific pressure, temperature, and fluid is the key to creating a truly reliable system.

I learned this the hard way early in my career. We had a huge production run for a client, and everything was going smoothly. I went home on a Friday feeling great. When I came in on Monday, the entire production floor was shut down. A single, cheap brass fitting on a cooling line had developed a pinhole leak over the weekend. It sprayed a fine mist of water directly onto a control panel, shorting out the entire cell. Weeks of work were ruined and the cost was enormous, all because someone tried to save a few dollars on a tiny part. That day, I realized that the smallest components often carry the biggest risk. You have to respect them, or they will make you sorry.

Is Brass Good Enough, or Do You Need Stainless Steel?

You need to connect a cooling line. Brass is cheaper and readily available. But what if it fails? The risk of corrosion and contamination could jeopardize the entire project.

Choosing the right material isn't about cost; it's about risk management. Brass is a reliable workhorse for standard water and air applications. However, for aggressive fluids, high temperatures, or food-grade processes, the superior corrosion resistance of stainless steel becomes essential.

Selecting the material for your valves and fittings is a critical decision that impacts the long-term reliability of your mold. It’s a trade-off between cost and performance. I always encourage designers to think about the "cost of failure" rather than just the "cost of the part." Does the fluid you are using have corrosive properties? Will the mold operate at elevated temperatures? Is this for a medical or food-grade application where contamination is unacceptable? Answering these questions guides your choice.

The Case for Brass: The Workhorse

Brass is an alloy of copper and zinc. It has good corrosion resistance for most common applications, especially for standard water cooling lines in molds. It is easy to machine, which makes brass fittings widely available and affordable. It is the default choice for general-purpose applications where conditions are not extreme.

When to Upgrade to Stainless Steel: The Fortress

Stainless steel is the premium choice. Its chromium content creates a passive layer that provides excellent protection against rust and corrosion, even with aggressive chemicals or deionized water. It also handles much higher temperatures than brass. For any medical, food-grade, or high-performance mold, stainless steel is not just an option; it's a requirement.

| Feature | Brass | Stainless Steel |

|---|---|---|

| Cost | Lower | Higher |

| Corrosion Resistance | Good for water/air | Excellent for chemicals/high purity |

| Temperature Limit | Lower (~400°F / 200°C) | Much Higher (>800°F / 425°C) |

| Best For | General cooling, non-corrosive fluids | Medical, food-grade, aggressive media |

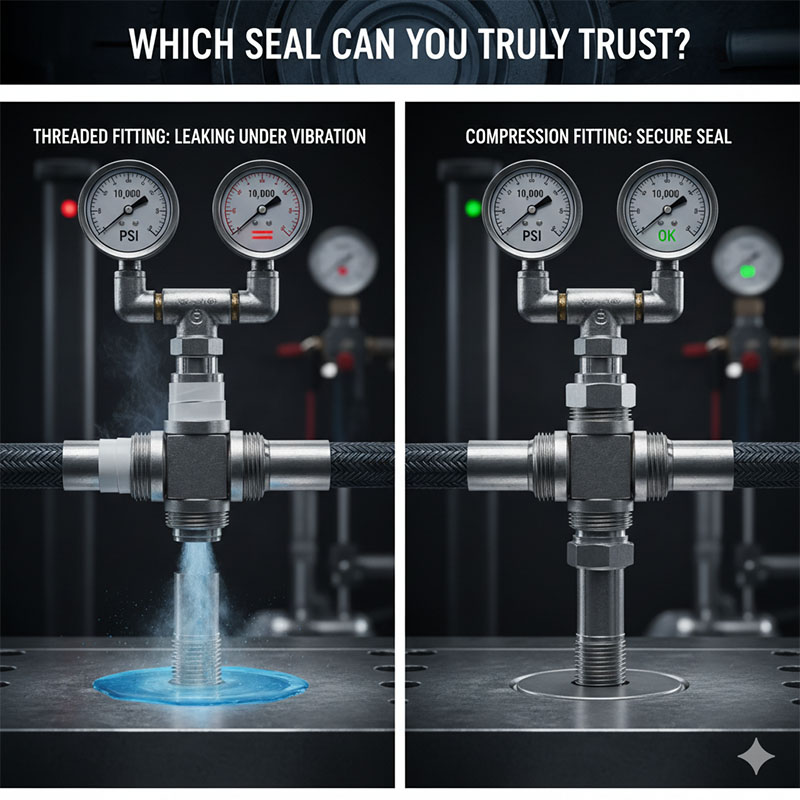

Threaded vs. Compression Fittings: Which Seal Can You Truly Trust?

You need to connect a high-pressure line. A standard threaded fitting is easy, but will it hold? A slow leak or a sudden blowout under pressure could be a disaster.

This choice determines your system's integrity under stress. Threaded fittings (like NPT) are common but rely on sealant and are vulnerable to vibration. Compression fittings create a superior mechanical seal that is far more resistant to leaks, pressure spikes, and vibration.

The a fitting connects parts is just as important as what it's made of. The two most common types in mold and industrial design are tapered threads and compression fittings. They work in fundamentally different ways and are suited for different jobs. I've seen countless "mystery leaks" that were simply a case of using a threaded fitting in a high-vibration environment where a compression fitting was needed. The vibrations slowly worked the connection loose over time, creating a small but persistent drip.

The Familiar Choice: Tapered Threads (NPT)

National Pipe Thread (NPT) is the most common type of threaded fitting. The threads are tapered, so as you tighten the male and female ends, they wedge together to form a seal. This design almost always requires a sealant like PTFE tape or pipe dope to fill the microscopic gaps. They are great for static applications like plumbing or permanent pipe installations where vibration is minimal. Their main weakness is that they can leak if under-tightened, or be damaged if over-tightened.

The High-Reliability Option: Compression Fittings

A compression fitting uses a different principle. It has three parts: the body, a ferrule (a small ring), and a nut. As you tighten the nut, it compresses the ferrule onto the pipe, creating an impressively strong mechanical grip and seal. This design is far superior for applications with vibration, pressure cycles, or thermal changes. It’s the standard for hydraulic systems and critical instrumentation for a reason. While more expensive, they provide peace of mind that threaded fittings can't match.

| Feature | Threaded (NPT) | Compression |

|---|---|---|

| Sealing Method | Thread deformation + sealant | Mechanical compression of a ferrule |

| Vibration Resistance | Poor | Excellent |

| Installation | Requires sealant, risk of over/under tightening | No sealant needed, simpler assembly |

| Best For | Static, low-vibration, low-cost systems | High pressure, vibration, critical applications |

Conclusion

Valves and fittings are not just commodity hardware; they are the guardians of your flow control. Investing in the right ones is a direct investment in your product's reliability.