How Can a Simple Brass Nozzle Boost Your Margins and Customer Loyalty?

You're using generic nozzles that wear out fast. This causes stringing, leaks, and costly downtime, frustrating your production team and eating into your profits with every bad part produced.

A high-quality brass nozzle builds loyalty by delivering consistency. Its superior heat transfer and durability reduce defects and downtime, making it a reliable component that engineers and production managers trust and re-order.

Jacky, your question reminds me of a panic-filled afternoon early in my career. We had a huge order for a major electronics brand, and their quality inspector was visiting the factory. We were running a tricky ABS plastic. Suddenly, the operator noticed black specks on the parts. The cause? A cheap nozzle that couldn't hold a stable temperature was degrading the plastic. We had to stop the machine, purge the barrel, and replace the nozzle, all while the client was watching. The savings from that cheap nozzle were wiped out in 30 minutes of downtime and scrap. It taught me that saving a few dollars on a critical component is one of the most expensive mistakes you can make.

Why Does the Specific Brass Alloy Make Such a Big Difference in Performance?

You assume all brass nozzles are basically the same. But you're dealing with inconsistent melt temperatures and premature orifice wear, especially with tougher materials, which leads to frustrating production defects.

A premium brass alloy offers superior thermal conductivity for rapid, stable heating. Its specific composition provides greater hardness and wear resistance, maintaining the orifice geometry for millions of cycles and ensuring consistent part quality.

The difference between a standard, generic brass and a high-performance alloy is something you feel in the final product. It's not just about melting plastic; it's about controlling that melt with precision. The material science here is critical. Standard yellow brass works, but it can be too soft and its thermal properties can vary. A purpose-engineered alloy, often with traces of other elements, provides a performance edge.

Material Properties That Matter

- Thermal Conductivity: This is the most important factor. The faster and more evenly a nozzle can transfer heat from the heater band to the plastic, the more stable your process will be. This reduces cycle times and prevents material degradation.

- Wear Resistance: Even unfilled plastics can be abrasive over time. A harder alloy prevents the nozzle's orifice from eroding or "washing out," which would change the shot size and gate quality.

- Machinability: The alloy must be able to be machined to incredibly tight tolerances, ensuring a smooth internal flow path with no dead spots where plastic could hang up and burn.

How Does a Component Part Actually Build Customer Loyalty?

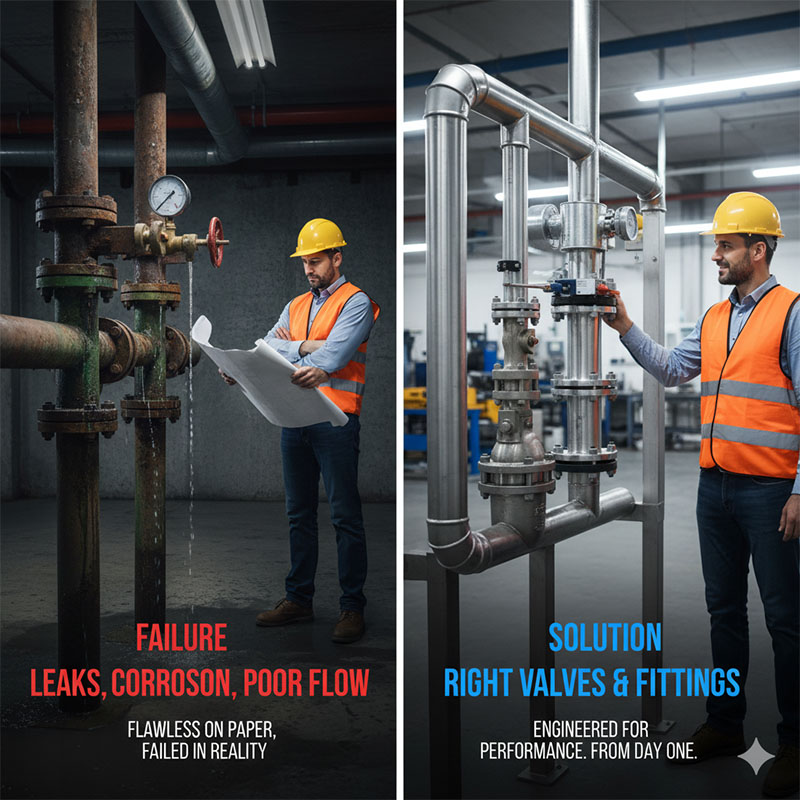

You're focused on the initial purchase price of components. But the frequent failures and unexpected downtime are frustrating your production team—your internal customers—and eroding trust in your design specifications.

Loyalty is built on reliability. When a component like a nozzle just works, it eliminates a source of production headaches. Engineers, technicians, and managers remember what's reliable and will specify it again, creating repeat business and trust.

We often think loyalty is about relationships and service, and it is. But in manufacturing, loyalty is also forged in performance. Every minute of unplanned downtime on a molding machine can cost hundreds of dollars. If a component you specified causes that downtime, it reflects poorly on you. Conversely, when a part runs smoothly for millions of cycles, it makes the whole team successful.

Total Cost of Ownership: The Real Math

The initial price is only a tiny part of the story. A premium component pays for itself many times over.

| Cost Factor | Standard (Cheap) Nozzle | Premium Brass Nozzle |

|---|---|---|

| Initial Cost | $20 | $40 |

| Expected Lifespan | 500,000 cycles | 2,000,000+ cycles |

| Downtime Events | 3-4 (replacement) | 0-1 (replacement) |

| Scrap Rate Impact | Higher due to wear | Lower due to stability |

| Total Cost / Cycle | Significantly Higher | Significantly Lower |

When your components are rock-solid, production runs smoothly, deadlines are met, and profits are protected. That's how a simple nozzle builds unshakable loyalty.

Which Molding Applications Benefit Most from a Premium Brass Nozzle?

You need to choose the right nozzle for every job. Using a generic nozzle for a demanding application can lead to poor results and premature failure, making your entire mold design seem less robust.

Premium brass nozzles excel with commodity resins like Polypropylene (PP), Polyethylene (PE), and Polystyrene (PS) where precise thermal control is critical. They are also ideal for jobs with frequent color changes due to their smooth internal finish.

While a premium brass nozzle is a fantastic workhorse, it's not the solution for everything. Knowing where it shines is key. This nozzle is the undisputed king for high-volume, general-purpose molding. It's the component you stock in depth because it covers the majority of your jobs. However, for highly specialized and aggressive materials, you need a different tool.

A Simple Nozzle Selection Guide

Here’s a quick guide I've used to help designers like you make the right call. The goal is to match the nozzle material to the plastic resin's properties.

| Plastic Resin Material | Recommended Nozzle Type | Key Reason |

|---|---|---|

| PP, PE, PS, ABS | Premium Brass | Excellent thermal control for great part quality and speed. |

| Nylon (Glass-Filled), PC | Hardened Tool Steel | High abrasion resistance is needed for the glass fibers. |

| PVC, CPVC | Stainless Steel | Corrosion resistance is essential to handle acidic gases. |

| PEEK, LCP | High-Temp Specialty Alloy | Maintains hardness at the very high processing temperatures. |

By choosing the premium brass nozzle for the right applications, you get the perfect balance of performance, lifespan, and cost, making it the most profitable and reliable part in your inventory.

Conclusion

A high-quality brass nozzle is more than a part; it's an investment in efficiency. It reduces downtime, improves quality, and builds the trust that is the foundation of long-term customer loyalty.