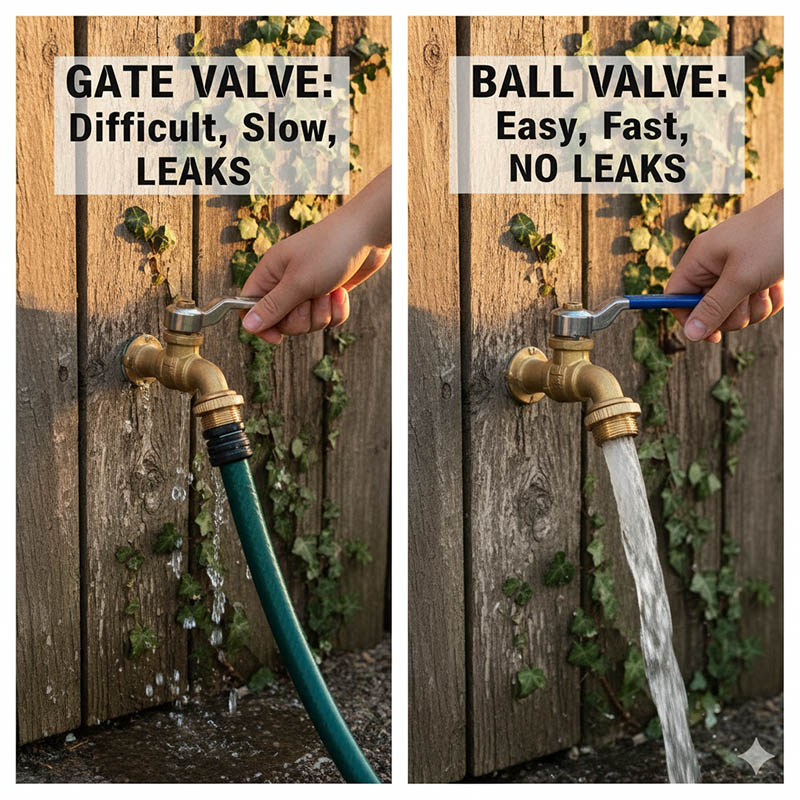

Gate Valve vs. Ball Valve: Which is Right for Your Garden Hose?

You grab your garden hose, but the outdoor spigot is a nightmare. The handle is stiff, it takes a dozen turns to open, and when you finally shut it off, it still drips.

For a garden hose, a ball valve is almost always the better choice. Its simple quarter-turn design provides a fast, reliable on/off function that is less prone to leaking. A gate valve is better suited for tasks that require fine-tuning the flow rate, not simple shutoff.

This question reminds me of a weekend project I had a few years ago. The spigot on the side of my house was leaking, driving me crazy with its constant dripping. It was an old-style gate valve, and I spent a frustrating hour trying to tighten it and replace the packing washer, only to make the leak worse. I finally gave up, went to the hardware store, and bought a modern quarter-turn ball valve. Installing it took 15 minutes. It worked perfectly with a flick of the wrist. No leaks, no effort. As I was cleaning up, I realized this was the exact same problem we face in industrial mold design, just on a smaller scale. Choosing the right component isn't just a technical detail; it's the difference between constant frustration and effortless reliability.

Why is a Ball Valve the Winning Choice for On/Off Control?

You just want to turn the water on or off, quickly and completely. So why are you struggling with a handle that needs endless turns and still allows a frustrating drip?

This is because you're using a valve designed for regulation, not for shutoff. A ball valve is built for one job: on/off control. Its simple, robust mechanism provides a fast, positive seal every time, making it the ideal choice for a garden hose.

The beauty of the ball valve is its simplicity, and as any good designer knows, simplicity leads to reliability. The internal mechanism is just a solid ball with a hole drilled through it. When you turn the handle a quarter turn, the hole aligns with the pipe, and water flows freely. When you turn it back, the solid side of the ball blocks the water completely. There are no delicate parts to wear out or get jammed with sediment from the water line. This is the exact reason we use ball valves in critical industrial applications, like isolating a specific cooling circuit on a mold. When a technician needs to shut off a line for maintenance, they need it to be fast, obvious, and 100% effective. A ball valve's handle clearly shows its state at a glance—aligned with the pipe means on, perpendicular means off.

The Internal Mechanics

A gate valve works by slowly lowering a solid "gate" to block the flow of water, like a miniature dam. This design requires multiple turns and the sliding gate can be a magnet for small debris and mineral buildup (scale). Over time, this buildup prevents the gate from seating properly, which is why they so often start to drip.

The Clear Winner for Shutoff Applications

A ball valve's smooth, wiping action as it closes helps clear debris from the sealing surfaces. It's a self-cleaning design. For any application where the primary job is to simply start or stop flow, the ball valve is superior.

| Feature | Ball Valve (Quarter-Turn) | Gate Valve (Multi-Turn) |

|---|---|---|

| Primary Use | On/Off Control | Throttling/Regulating Flow |

| Operation Speed | Very Fast (90° turn) | Slow (Multiple rotations) |

| Durability | High (Simple design) | Moderate (Prone to wear/debris) |

| Sealing Ability | Excellent, positive shutoff | Good, but prone to leaks over time |

| Industrial Parallel | Main shutoffs, circuit isolation | Balancing flow in distribution lines |

So, When Would You Ever Want a Gate Valve?

You're trying to water delicate seedlings and the full blast from the hose is too strong. But when you try to partially close your ball valve, it's either on or off, with no control.

This is the one scenario where a gate valve shines. It is designed specifically for throttling—the act of precisely controlling the volume of flow. Partially opening the valve allows you to fine-tune the output, which is something a ball valve is very bad at.

While a gate valve is a poor choice for a simple shutoff, its design is perfect for regulation. As you slowly turn the handle, the gate raises or lowers incrementally, giving you a smooth, linear change in the flow rate. Trying to do this with a ball valve is a recipe for problems. When you partially open a ball valve, the high-velocity water blasts one side of the ball and the internal seals. This creates turbulent flow and can quickly erode the components, a phenomenon called "jetting." This uneven wear will eventually prevent the valve from ever sealing properly again, even in the fully closed position. In the industrial world, this principle is critical. For sensitive processes that require precise a flow rate of cooling water or hydraulic fluid, we would never use a ball valve for control. We would choose a specialized globe valve or needle valve, which operate on the same principle as the gate valve but offer even finer control.

The Right Tool for the Job

Think of it like using a light switch versus a dimmer switch. A ball valve is a light switch: it's either on or it's off. A gate valve is a dimmer switch: it allows you to choose any level of brightness in between.

Matching Valve Type to Application

Understanding this fundamental difference is key to designing any fluid system, from a garden hose to a multi-million dollar injection mold. Using the wrong valve type leads to poor performance and premature failure.

| Task | Recommended Valve | Why it Works Best |

|---|---|---|

| Garden Hose Shutoff | Ball Valve | Fast operation, reliable seal, long life. |

| Isolating a Mold Circuit | Ball Valve | Quick visual confirmation, positive shutoff for safety. |

| Adjusting Sprinkler Flow | Gate Valve (or Globe Valve) | Allows fine-tuning of flow without damaging the valve. |

| Balancing Multiple Cooling Lines | Needle Valve (a type of Gate Valve) | Provides very precise control to ensure even cooling. |

Conclusion

For your garden hose, choose a ball valve for simple, leak-free operation. But remember the principle: use ball valves for on/off tasks and gate valves for fine-tuning flow.