Why Are High-Quality Valves the Unseen Backbone of Industrial Reliability?

Your entire production process is running smoothly, but a single, cheap valve starts to leak. Suddenly, you're facing a costly shutdown, potential safety hazards, and a damaged reputation.

A high-quality valve isn't an expense; it's insurance against failure. This reliability comes from superior material science, extreme manufacturing precision, and rigorous testing, ensuring that your operations stay safe and productive.

Early in my career at the factory, I saw something I'll never forget. A main steam line blew out because a valve failed. It wasn't a huge explosion, but the sudden release of high-pressure steam was terrifying, and it shut down that entire section of the plant for days. The investigation found that the valve that failed was a cheaper, off-brand model purchased to save a few hundred dollars. That "savings" ended up costing the company tens of thousands in repairs and lost production. That day taught me a lesson that has stuck with me forever: some components are too important to compromise on. Valves are the gatekeepers of your entire process. They control the flow, pressure, and safety of everything you do. Choosing a high-quality valve isn't just a mechanical decision; it's a core business decision.

How Can the Wrong Metal in a Valve Cripple Your Entire Production Line?

You're trying to control a corrosive fluid, but your standard valve is already showing signs of pitting and failure after only a few months, forcing an unplanned and expensive replacement.

The problem lies in the material. A generic valve uses basic alloys, but true reliability comes from choosing a specific material, like SS316 or specialized brass, designed to resist your exact operational chemistry.

For a designer like you, Jacky, this is where a deep understanding of materials science pays off. A valve body isn't just a chunk of metal; it's a carefully selected barrier between the process fluid and the outside world. A standard 304 stainless steel valve might be fine for water, but it will get eaten alive by chlorides. The wrong type of brass can become brittle in certain chemical environments. A truly reliable supplier won't just sell you a "stainless steel valve." They will ask what's flowing through it, at what temperature, and at what pressure. Choosing the right material from the start prevents corrosion, ensures safety, and dramatically extends the service life of the valve, saving you from a cycle of constant replacement and downtime.

Common Valve Body Materials Compared

| Material | Best For | Weak Against | Cost Factor |

|---|---|---|---|

| Brass | Water, oil, air, non-corrosive gas | Ammonia, high chlorides, acetone | Low |

| 304 Stainless Steel | Water, food-grade applications | Chlorides, strong acids/alkalis | Medium |

| 316 Stainless Steel | Corrosive fluids, marine uses | High temperatures (above 800°C) | Medium-High |

| Carbon Steel | High-temp steam, oil, gas | Corrosive fluids unless lined | Medium |

Why Does a Thousandth of an Inch Matter So Much in Valve Performance?

You install a brand-new ball valve, but you can't get a perfect seal. There's a slow, persistent drip that contaminates your process or creates a mess on the factory floor.

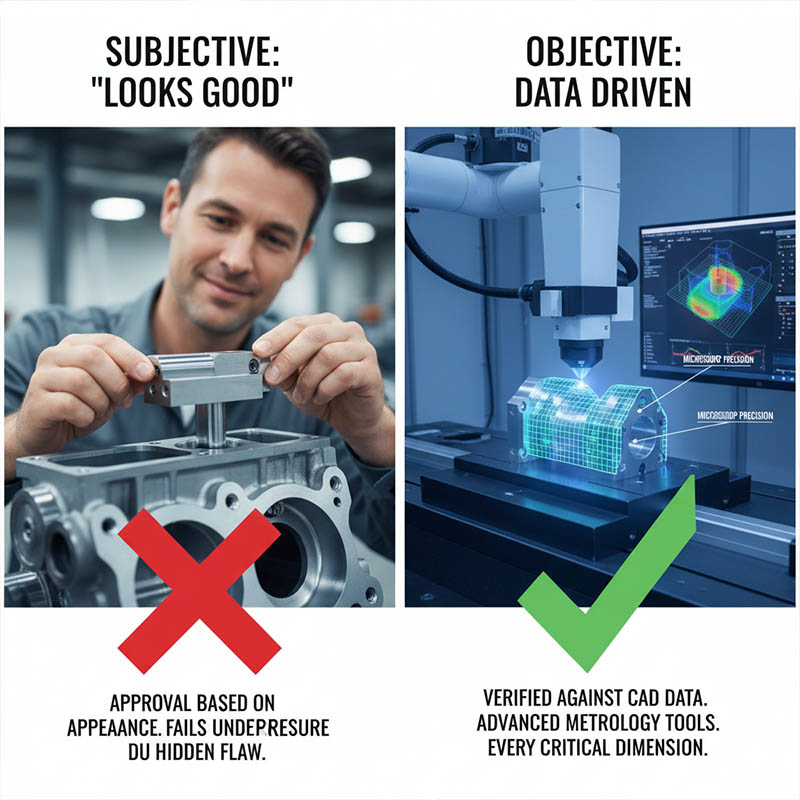

This frustrating leak is caused by poor manufacturing tolerances. A valve only works if its sealing components—the ball and the seats—are machined with extreme precision to create a perfect, void-free fit.

We love to talk about big, strong machines, but reliability often comes down to the smallest measurements. A valve is a system of moving parts. The "ball" in a ball valve has to be perfectly spherical. The "seats" it rests against have to be perfectly matched to its curvature. If the ball is slightly out-of-round, or if the surface finish on the seats has microscopic scratches, a leak path is created. This is why high-quality valve manufacturers are obsessed with precision CNC machining and grinding. We're not talking about "close enough." We're talking about tolerances measured in microns (thousandths of a millimeter). This level of precision, which is impossible to see with the naked eye, is what ensures a bubble-tight seal, first time, every time. It’s the difference between a valve that works and a valve that almost works.

Key Areas of Valve Machining Precision

- Ball Sphericity: The ball must be a near-perfect sphere to ensure uniform contact with the seats at all points of rotation.

- Seat Surface Finish: The PTFE or metal seats must have an ultra-smooth finish to eliminate microscopic leak paths.

- Stem Alignment: The shaft connecting the handle to the ball must be perfectly centered to prevent side-loading and uneven wear on the seats.

Is Your Valve's 'Pass' Just a Guess Without Rigorous Testing?

You trust the pressure rating stamped on the valve body. But when a pressure spike occurs in your system, the valve casing cracks, creating a dangerous and costly process failure.

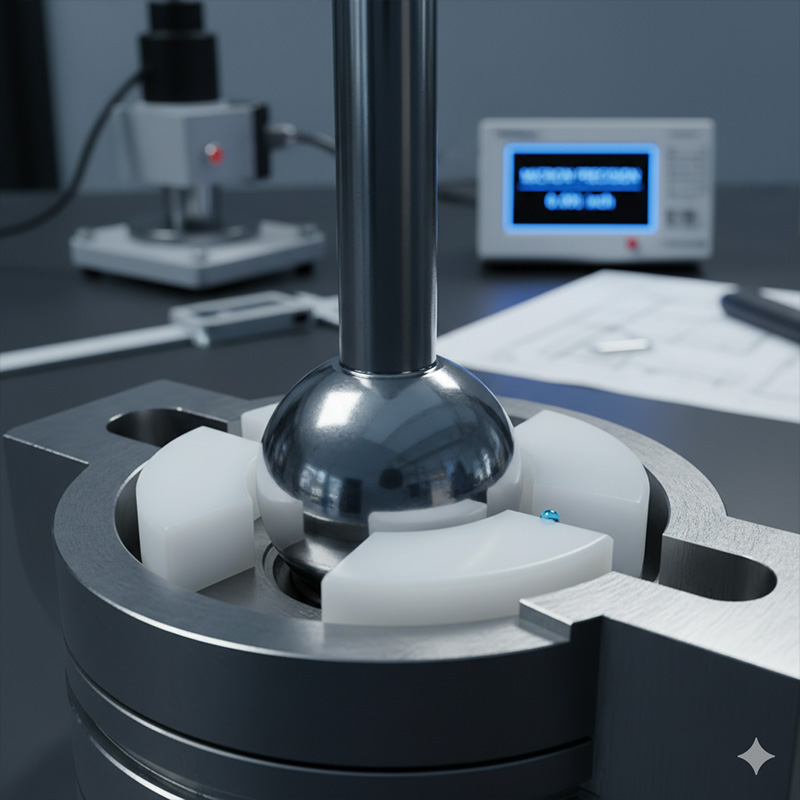

That stamped number is meaningless without proof. A quality valve is validated through rigorous, documented pressure testing on every single unit, proving it can safely handle its stated limits and beyond.

I can machine a part and stamp "1000 PSI" on it, but that doesn't make it true. The final, and maybe most important, step in ensuring reliability is testing. This is where a manufacturer puts their money where their mouth is. For every critical valve, there should be a documented testing procedure. The most common is a hydrostatic test. The valve is filled with water and pressurized to 1.5 times its working pressure rating to ensure the body (or "shell") is sound and won't leak or burst. Then, a seat leakage test is done, usually with air, to confirm it seals perfectly in the closed position. For a serious buyer, you should be able to request test certificates for your batch. This documentation is your guarantee that the valve in your hand is not just a guess; it's a proven, verified piece of safety equipment.

Understanding Common Valve Tests

| Test Type | What It Does | Why It Matters | Standard |

|---|---|---|---|

| Hydrostatic Shell Test | Pressurizes the valve body. | Confirms the valve won't burst under maximum pressure. | API 598 |

| Pneumatic Seat Test | Applies air pressure to one side. | Checks for bubble-tight shutoff and internal leaks. | API 598 |

| Cycle Testing | Opens and closes the valve thousands of times. | Confirms long-term durability of the stem and seals. | Manufacturer Specific |

Conclusion

A high-quality valve is the foundation of industrial reliability. It's an investment in safety, productivity, and peace of mind that pays for itself every day your process runs without failure.