Is Your Steam Boiler a Gentle Giant or an Explosive Powerhouse?

You design a brilliant piece of equipment that uses steam. You assume the steam supply from the wall is consistent and reliable. But it's not.

The problem isn't your design; it's the boiler you can't see. Understanding if your facility uses a massive, slow fire-tube boiler or a fast, high-pressure water-tube boiler is the secret to creating a product that actually works in the real world.

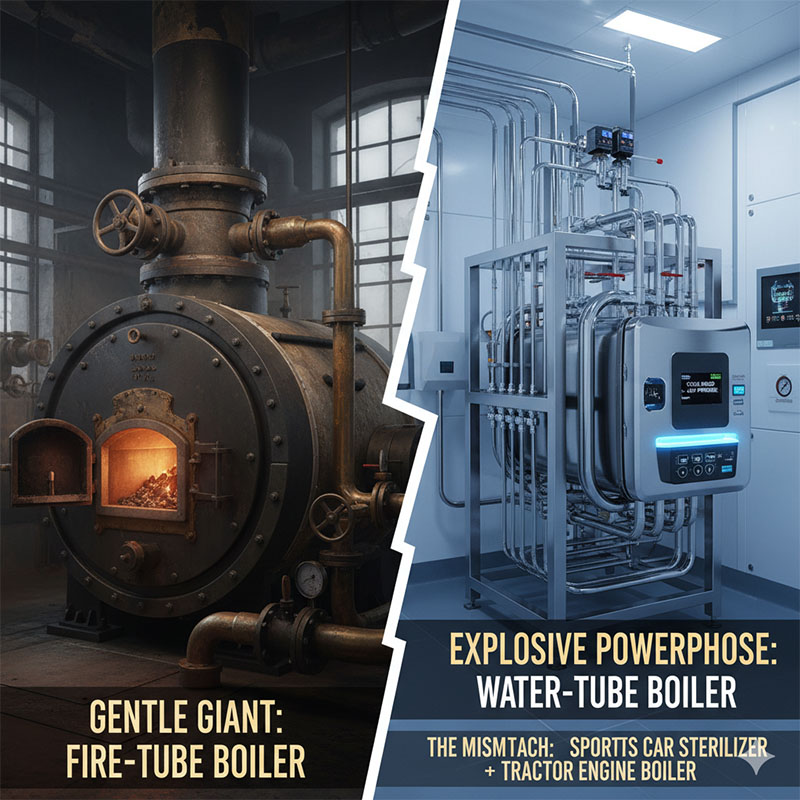

I once worked with a company that developed a state-of-the-art sterilizer for medical tools. Their design was perfect—on paper. It required precise, rapid pulses of steam to meet strict cycle times. But when they installed the first unit at a hospital, it failed miserably. The cycles were taking twice as long as they should. The client was furious. I flew out to the site and the first thing I asked to see was the hospital's boiler room. Down in the basement was a massive, old fire-tube boiler. It was a "gentle giant," great for heating the building, but it couldn't respond to the sterilizer's sudden demands for steam. The pressure would drop and take forever to recover. They had designed a sports car but connected it to a tractor engine.

Is the "Fire-Tube" Boiler a Gentle Giant Holding You Back?

Your process needs a large, steady supply of high-quality steam. But when demand suddenly changes, your system's pressure drops and it's slow to recover, ruining your efficiency.

This is the classic sign of a fire-tube boiler. It holds a huge volume of water, acting like a thermal battery. This makes it incredibly stable for consistent loads, but very slow to react to changes.

Think of a fire-tube boiler like a giant pot of water on the stove with the lid on. The heat source—the fire—is ducted through tubes running through the water. Because there is a massive volume of water to heat, it takes a long time to get up to temperature and start producing steam. Once it's running, however, that huge thermal mass makes it very stable. It produces consistent, high-quality "dry" steam, which is great for continuous processes like heating or simple sterilization. But if your application suddenly draws a large amount of steam, the pressure will drop, and it will take that massive pot of water a long time to "catch up" and rebuild pressure. As a designer, if your product needs quick bursts of steam, and you're connected to a fire-tube boiler, you will have a problem.

The Designer's Reality: Pros and Cons

- ### The Big Picture Fire-tube boilers are the workhorses for applications that need stability over speed. They are simpler in construction and more forgiving.

- ### The Trade-Off You get stability and high-quality steam at the cost of slow response time and lower pressure limits (typically under 350 PSI).

| Feature | Fire-Tube Boiler Performance | Why It Matters to Your Design |

|---|---|---|

| Response Time | Very Slow | Your product must have a steady, predictable steam demand. Avoid pulsed or variable loads. |

| Steam Quality | High (Dry) & Stable | Excellent for processes sensitive to water droplets in the steam line. |

| Pressure | Low to Medium | Not suitable for high-pressure turbines or applications needing >350 PSI. |

| Ideal Application | Building heating, food processing, large steady-state industrial processes. | A great, reliable choice if your load doesn't change quickly. |

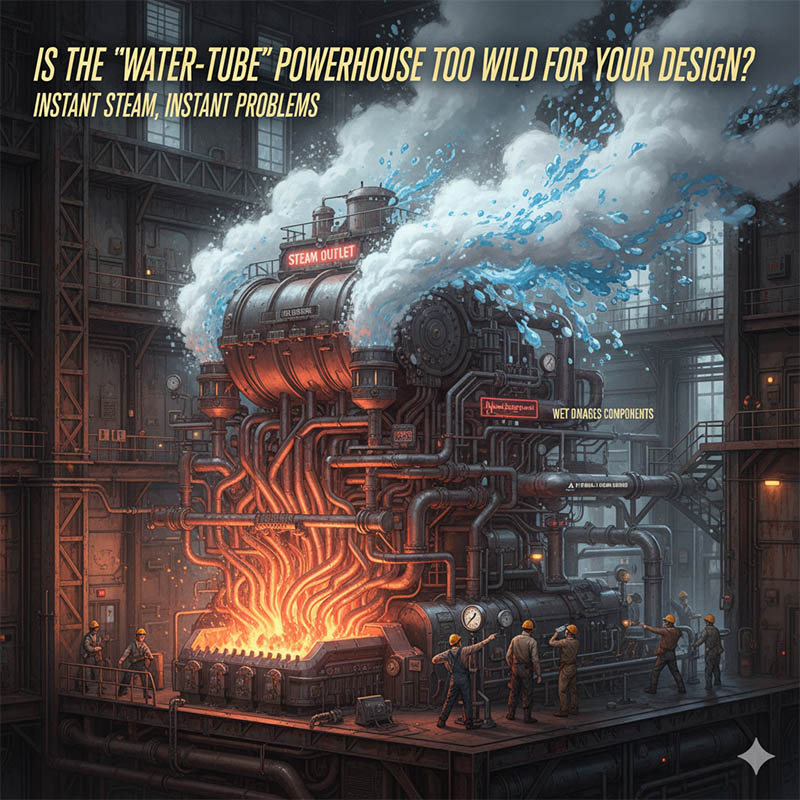

Is the "Water-Tube" Powerhouse Too Wild for Your Design?

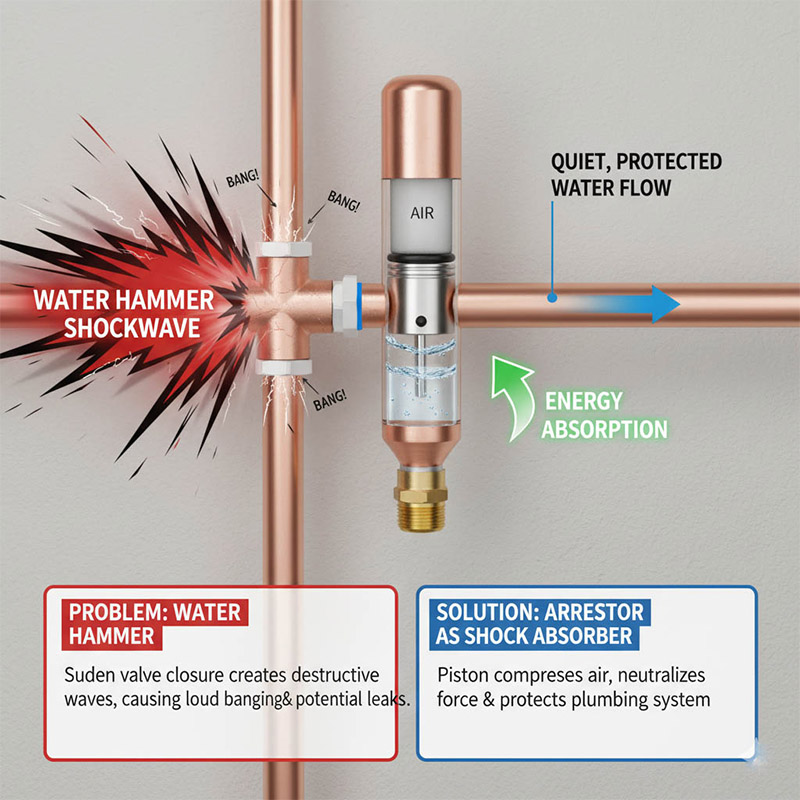

Your application needs steam right now, and lots of it. But you're constantly battling pressure fluctuations and "wet" steam that carries too much water and damages components.

You are likely connected to a water-tube boiler. Its design allows it to make steam incredibly fast, but this speed comes at the cost of the stability found in its larger cousin.

Now, imagine the opposite design. Instead of fire in the tubes, the water is in the tubes, and the fire is on the outside. This is a water-tube boiler. Because you are only heating the small amount of water inside the tubes, it can turn to steam almost instantly. This makes these boilers extremely responsive and allows them to generate steam at incredibly high pressures, often thousands of PSI. They are the standard for power generation plants and large industrial facilities that need a lot of energy, fast. The downside? They hold very little reserve water. A sudden increase in demand can cause pressure to fluctuate. They are also more susceptible to producing "wet" steam (steam with more water droplets) if the load changes too rapidly. If your design has delicate controls or is sensitive to water hammer, a wild water-tube boiler can be your worst enemy.

The Designer's Reality: Pros and Cons

- ### The Big Picture Water-tube boilers are high-performance machines built for speed and high-pressure applications.

- ### The Trade-Off You get rapid response and high pressure, but you must design your system to handle potential instability and lower-quality steam.

| Feature | Water-Tube Boiler Performance | Why It Matters to Your Design |

|---|---|---|

| Response Time | Very Fast | Perfect for applications with highly variable or rapidly changing steam loads. |

| Steam Quality | Can be less stable ("Wet") | Your design may need steam traps or separators to protect sensitive components. |

| Pressure | Very High | The only choice for power generation and applications needing thousands of PSI. |

| Ideal Application | Power plants, large refineries, any process needing fast, high-pressure steam. | The powerhouse option, but your design must be robust enough to handle it. |

Conclusion

The boiler is not just a utility. It's the heart of your steam system. By understanding its personality—gentle giant or wild powerhouse—you can design a product that thrives.